Journal of Agricultural Science and Technology ›› 2024, Vol. 26 ›› Issue (8): 112-121.DOI: 10.13304/j.nykjdb.2023.0029

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Xiuquan ZHANG( ), Wanping FENG, Jiawei WANG, Haiyan SONG, Decong ZHENG(

), Wanping FENG, Jiawei WANG, Haiyan SONG, Decong ZHENG( )

)

Received:2023-01-11

Accepted:2023-03-22

Online:2024-08-15

Published:2024-08-12

Contact:

Decong ZHENG

通讯作者:

郑德聪

作者简介:张秀全 E-mail:zhangxiuq1980@126.com;

基金资助:CLC Number:

Xiuquan ZHANG, Wanping FENG, Jiawei WANG, Haiyan SONG, Decong ZHENG. Design and Performance of a Kneading Threshing Device for Sorghum[J]. Journal of Agricultural Science and Technology, 2024, 26(8): 112-121.

张秀全, 冯晚平, 王嘉伟, 宋海燕, 郑德聪. 揉搓式高粱脱粒装置的设计与性能试验[J]. 中国农业科技导报, 2024, 26(8): 112-121.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2023.0029

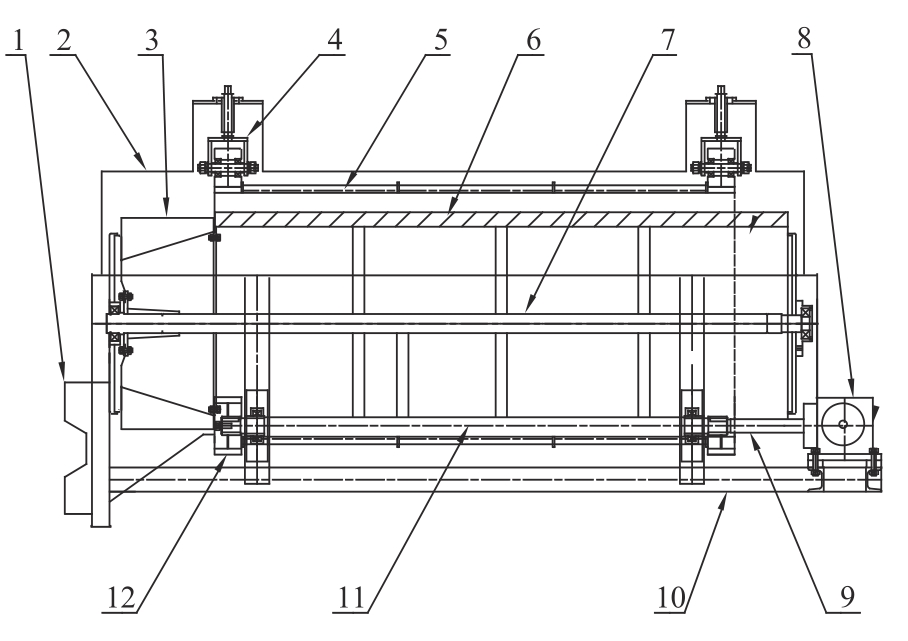

Fig. 1 Structure of kneading sorghum threshing deviceNote: 1—Feeding entrance; 2—Top cover; 3—Screw feeding device; 4—Grid roller pressing device; 5—Grid roller; 6—Rasp bar threshing roller;7—Threshing drum spindle; 8—Reducer; 9—Discharging gap;10—Machine frame; 11—Friction wheel drive shaft; 12—Friction wheel.

| 参数Parameter | 数值Value |

|---|---|

| 株高 Plant height/cm | 145~153 |

| 籽粒平均含水率 Grain average moisture content/% | 11.85 |

| 茎秆平均含水率/% Stem average moisture content/% | 40.04 |

| 谷草比 Grain to grass ratio | 1.34∶1.00 |

| 千粒重 Thousand weight/g | 22.6 |

Table 1 Main properties of buckwheat

| 参数Parameter | 数值Value |

|---|---|

| 株高 Plant height/cm | 145~153 |

| 籽粒平均含水率 Grain average moisture content/% | 11.85 |

| 茎秆平均含水率/% Stem average moisture content/% | 40.04 |

| 谷草比 Grain to grass ratio | 1.34∶1.00 |

| 千粒重 Thousand weight/g | 22.6 |

水平 Level | 因素 Factor | ||

|---|---|---|---|

x1:喂入量 Feed amount/(kg·s-1) | x2:纹杆滚筒转速 Rasp bar roller speed/(r·min-1) | x3:栅格滚筒转速 Grid roller speed/(r·min-1) | |

| +1.682 | 67.05 | 484.1 | 1.364 0 |

| +1 | +50.00 | 450.0 | 1.000 0 |

| 0 | +25.00 | 400.0 | 0.800 0 |

| -1 | 0 | 350.0 | 0.600 0 |

| -1.682 | 17.05 | 315.9 | 0.463 6 |

| Δ | 25.00 | 50.0 | 0.200 0 |

Table 2 Factor level

水平 Level | 因素 Factor | ||

|---|---|---|---|

x1:喂入量 Feed amount/(kg·s-1) | x2:纹杆滚筒转速 Rasp bar roller speed/(r·min-1) | x3:栅格滚筒转速 Grid roller speed/(r·min-1) | |

| +1.682 | 67.05 | 484.1 | 1.364 0 |

| +1 | +50.00 | 450.0 | 1.000 0 |

| 0 | +25.00 | 400.0 | 0.800 0 |

| -1 | 0 | 350.0 | 0.600 0 |

| -1.682 | 17.05 | 315.9 | 0.463 6 |

| Δ | 25.00 | 50.0 | 0.200 0 |

序号 Serial number | 因素水平Factor level | y1:夹带损失率Entrainment loss rate/% | y2:籽粒破碎率 Grain breakage rate/% | ||

|---|---|---|---|---|---|

x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed | |||

| 1 | 1 | 1 | 1 | 2.34 | 0.39 |

| 2 | 1 | 1 | -1 | 2.64 | 0.31 |

| 3 | 1 | -1 | 1 | 2.41 | 0.29 |

| 4 | 1 | -1 | -1 | 2.07 | 0.24 |

| 5 | -1 | 1 | 1 | 0.74 | 0.53 |

| 6 | -1 | 1 | -1 | 1.73 | 0.51 |

| 7 | -1 | -1 | 1 | 2.15 | 0.35 |

| 8 | -1 | -1 | -1 | 1.98 | 0.28 |

| 9 | 1.682 | 0 | 0 | 2.80 | 0.22 |

| 10 | -1.682 | 0 | 0 | 1.34 | 0.41 |

| 11 | 0 | 1.682 | 0 | 1.44 | 0.51 |

| 12 | 0 | -1.682 | 0 | 2.86 | 0.34 |

| 13 | 0 | 0 | 1.682 | 1.76 | 0.43 |

| 14 | 0 | 0 | -1.682 | 1.62 | 0.41 |

| 15 | 0 | 0 | 0 | 1.56 | 0.22 |

| 16 | 0 | 0 | 0 | 1.01 | 0.24 |

| 17 | 0 | 0 | 0 | 1.04 | 0.23 |

| 18 | 0 | 0 | 0 | 0.96 | 0.19 |

| 19 | 0 | 0 | 0 | 1.03 | 0.22 |

| 20 | 0 | 0 | 0 | 0.95 | 0.24 |

Table 3 Experimental plan and results

序号 Serial number | 因素水平Factor level | y1:夹带损失率Entrainment loss rate/% | y2:籽粒破碎率 Grain breakage rate/% | ||

|---|---|---|---|---|---|

x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed | |||

| 1 | 1 | 1 | 1 | 2.34 | 0.39 |

| 2 | 1 | 1 | -1 | 2.64 | 0.31 |

| 3 | 1 | -1 | 1 | 2.41 | 0.29 |

| 4 | 1 | -1 | -1 | 2.07 | 0.24 |

| 5 | -1 | 1 | 1 | 0.74 | 0.53 |

| 6 | -1 | 1 | -1 | 1.73 | 0.51 |

| 7 | -1 | -1 | 1 | 2.15 | 0.35 |

| 8 | -1 | -1 | -1 | 1.98 | 0.28 |

| 9 | 1.682 | 0 | 0 | 2.80 | 0.22 |

| 10 | -1.682 | 0 | 0 | 1.34 | 0.41 |

| 11 | 0 | 1.682 | 0 | 1.44 | 0.51 |

| 12 | 0 | -1.682 | 0 | 2.86 | 0.34 |

| 13 | 0 | 0 | 1.682 | 1.76 | 0.43 |

| 14 | 0 | 0 | -1.682 | 1.62 | 0.41 |

| 15 | 0 | 0 | 0 | 1.56 | 0.22 |

| 16 | 0 | 0 | 0 | 1.01 | 0.24 |

| 17 | 0 | 0 | 0 | 1.04 | 0.23 |

| 18 | 0 | 0 | 0 | 0.96 | 0.19 |

| 19 | 0 | 0 | 0 | 1.03 | 0.22 |

| 20 | 0 | 0 | 0 | 0.95 | 0.24 |

评价指标 Evaluation index | 变异来源 Sources of variation | 平方和 Sum of squares | 自由度 df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | 回归Regression | 7.62 | 8 | 14.36 | <0.000 1 |

| 剩余Residual | 0.73 | 11 | — | — | |

| 误差Error | 0.27 | 5 | — | — | |

| 总和 Cortotal | 8.35 | 19 | — | — | |

y2:籽粒破碎率 Grain breakage rate | 回归Regression | 0.22 | 7 | 38.55 | <0.000 1 |

| 剩余Residual | 0.009 6 | 12 | — | — | |

| 误差Error | 0.001 7 | 5 | — | — | |

| 总和Cortotal | 0.23 | 19 | — | — |

Table 4 Variance analysis of entrainment loss rate test results

评价指标 Evaluation index | 变异来源 Sources of variation | 平方和 Sum of squares | 自由度 df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | 回归Regression | 7.62 | 8 | 14.36 | <0.000 1 |

| 剩余Residual | 0.73 | 11 | — | — | |

| 误差Error | 0.27 | 5 | — | — | |

| 总和 Cortotal | 8.35 | 19 | — | — | |

y2:籽粒破碎率 Grain breakage rate | 回归Regression | 0.22 | 7 | 38.55 | <0.000 1 |

| 剩余Residual | 0.009 6 | 12 | — | — | |

| 误差Error | 0.001 7 | 5 | — | — | |

| 总和Cortotal | 0.23 | 19 | — | — |

评价指标 Evaluation index | 因素 factors | 平方和 Sum of squares | 自由度 Df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | x1 | 2.06 | 1 | 32.20 | 0.000 2** |

| x2 | 0.91 | 1 | 14.27 | 0.003 6** | |

| x3 | 0.02 | 1 | 0.33 | 0.580 5 | |

| x1x2 | 0.58 | 1 | 9.09 | 0.013 0* | |

| x1x3 | 0.09 | 1 | 1.39 | 0.265 6 | |

| x2x3 | 0.40 | 1 | 6.27 | 0.031 2* | |

| x12 | 1.69 | 1 | 26.32 | 0.000 4** | |

| x22 | 1.98 | 1 | 30.87 | 0.000 2** | |

| x32 | 0.63 | 1 | 9.76 | 0.010 8* | |

y2:籽粒破碎率 Grain breakage rate | x1 | 0.004 | 1 | 3.67 | 0.084 4 |

| x2 | 0.078 | 1 | 61.01 | <0.000 1** | |

| x3 | 0.042 | 1 | 32.91 | 0.000 2** | |

| x1x2 | 0.000 05 | 1 | 0.04 | 0.847 5 | |

| x1x3 | 0.000 2 | 1 | 0.16 | 0.701 3 | |

| x2x3 | 0.007 | 1 | 5.61 | 0.039 4* | |

| x12 | 0.050 | 1 | 38.57 | 0.000 1** | |

| x22 | 0.088 | 1 | 68.42 | <0.000 1** | |

| x32 | 0.006 | 1 | 5.18 | 0.046 0* |

Table 5 Variance analysis of Grain breakage rate test result

评价指标 Evaluation index | 因素 factors | 平方和 Sum of squares | 自由度 Df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | x1 | 2.06 | 1 | 32.20 | 0.000 2** |

| x2 | 0.91 | 1 | 14.27 | 0.003 6** | |

| x3 | 0.02 | 1 | 0.33 | 0.580 5 | |

| x1x2 | 0.58 | 1 | 9.09 | 0.013 0* | |

| x1x3 | 0.09 | 1 | 1.39 | 0.265 6 | |

| x2x3 | 0.40 | 1 | 6.27 | 0.031 2* | |

| x12 | 1.69 | 1 | 26.32 | 0.000 4** | |

| x22 | 1.98 | 1 | 30.87 | 0.000 2** | |

| x32 | 0.63 | 1 | 9.76 | 0.010 8* | |

y2:籽粒破碎率 Grain breakage rate | x1 | 0.004 | 1 | 3.67 | 0.084 4 |

| x2 | 0.078 | 1 | 61.01 | <0.000 1** | |

| x3 | 0.042 | 1 | 32.91 | 0.000 2** | |

| x1x2 | 0.000 05 | 1 | 0.04 | 0.847 5 | |

| x1x3 | 0.000 2 | 1 | 0.16 | 0.701 3 | |

| x2x3 | 0.007 | 1 | 5.61 | 0.039 4* | |

| x12 | 0.050 | 1 | 38.57 | 0.000 1** | |

| x22 | 0.088 | 1 | 68.42 | <0.000 1** | |

| x32 | 0.006 | 1 | 5.18 | 0.046 0* |

评价指标 Evaluation index | x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed |

|---|---|---|---|

| y1:夹带损失率Entrainment loss rate | 2.52 | 2.76 | 1.46 |

| y2:籽粒破碎率Grain breakage rate | 1.78 | 2.41 | 2.32 |

Table 6 Contribution rate of each factor to the test index

评价指标 Evaluation index | x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed |

|---|---|---|---|

| y1:夹带损失率Entrainment loss rate | 2.52 | 2.76 | 1.46 |

| y2:籽粒破碎率Grain breakage rate | 1.78 | 2.41 | 2.32 |

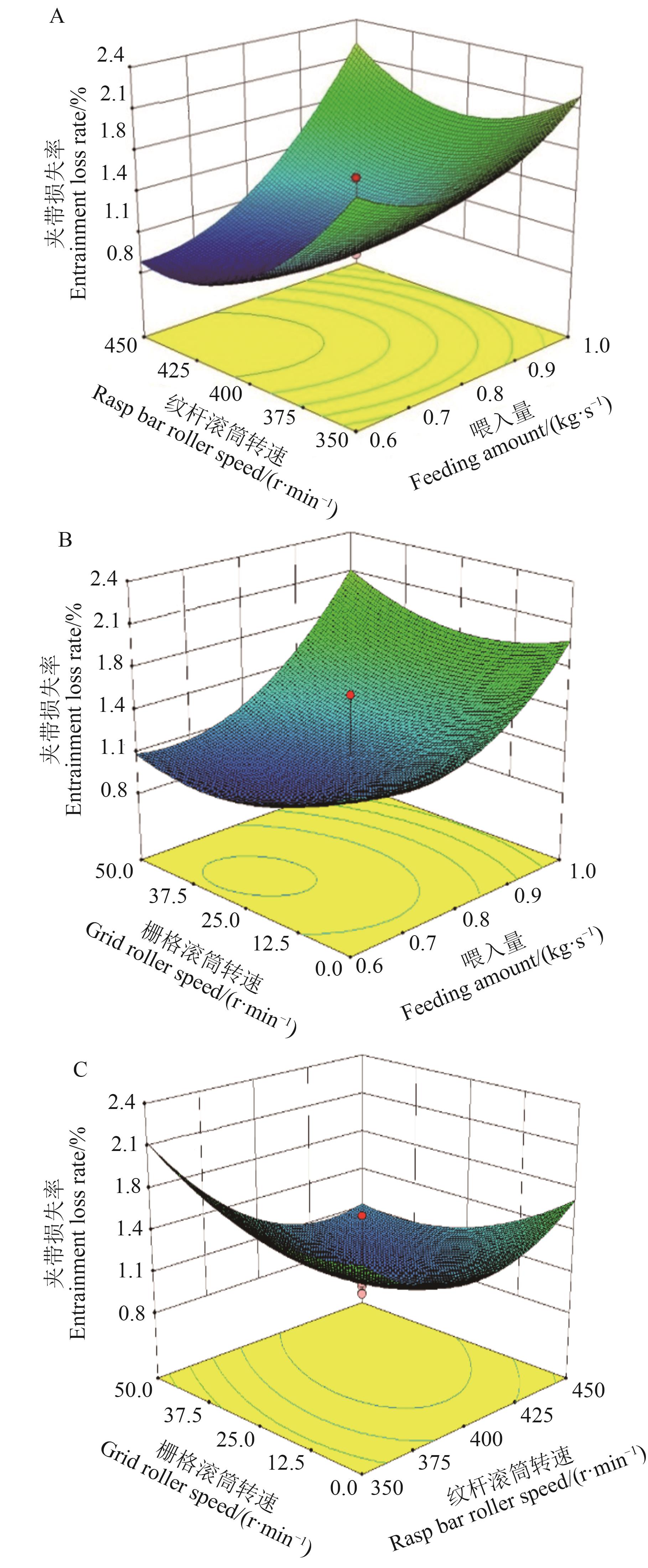

Fig. 6 Effect of double factors on entrainment loss rateA: Rasp bar roller speed and feed amount; B: Grid roller speed and feed amount; C: Grid roller speed and rasp bar roller speed

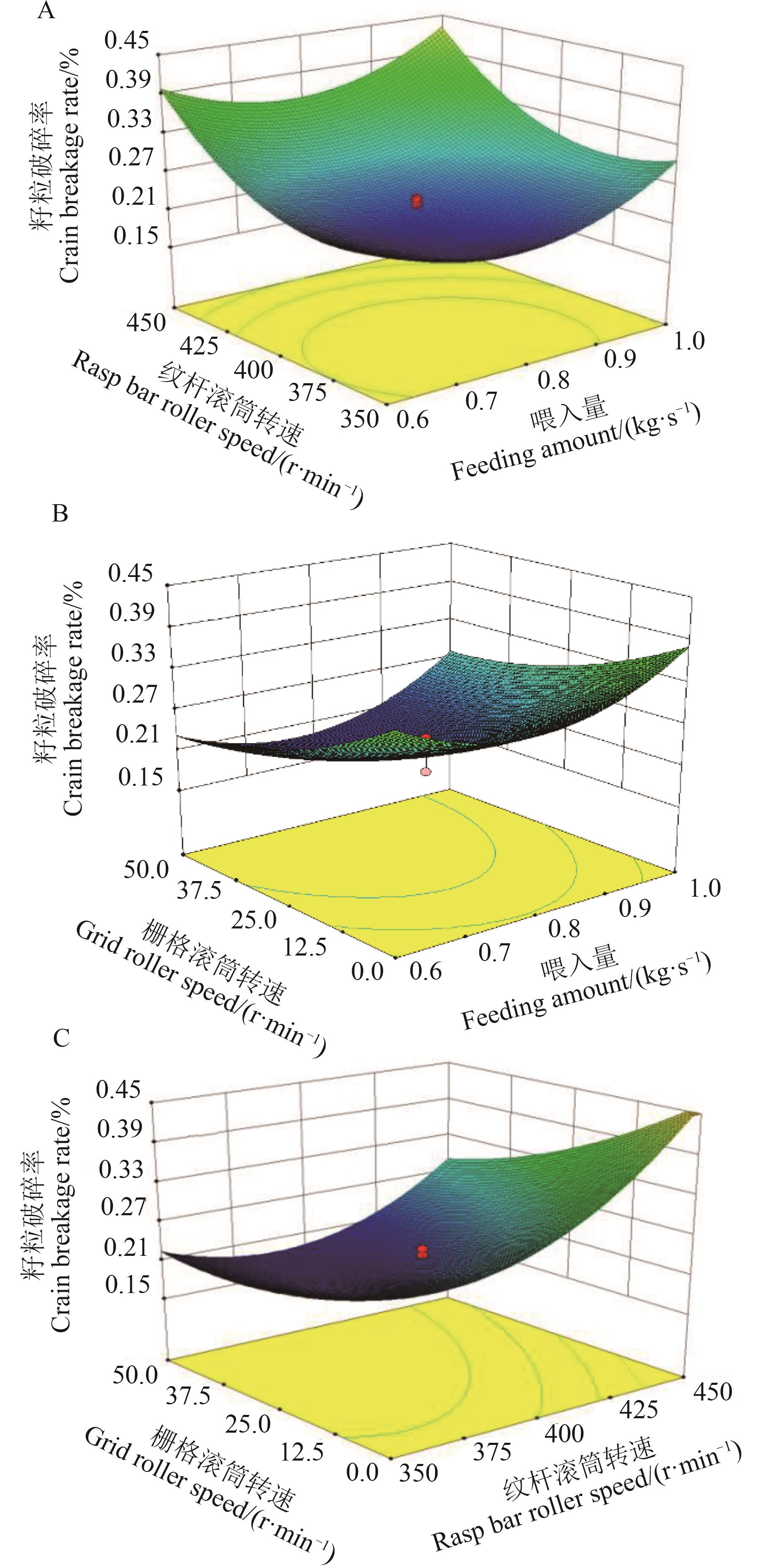

Fig. 7 Effect of double factors on kernel breakageA: Rasp bar roller speed and feed amount; B: Grid roller speed and feed amount; C: Grid roller speed and rasp bar roller speed

| 1 | 陈朝儒,王智,马强,等.甜高粱茎汁及茎渣同步糖化发酵工艺优化[J].农业工程学报.2016,32(3):253-258. |

| CHEN C R, WANG Z, MA Q, et al.. Optimization of ethanol production from bagasse and juice of sweet sorghum stem by simultaneous saccharification and fermentation [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(3): 253-258. | |

| 2 | 杨森,王石垒,张雷,等.甜高粱茎秆残渣生料多菌种固态发酵生产蛋白饲料[J].农业工程学报.2015,31(15):309-314. |

| YANG S, WANG S L, ZHANG L, et al.. Producing protein feedstuff by multiple strains solid-state fermentation with raw sweet sorghum stalk residue [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(15): 309-314. | |

| 3 | 韩立朴,马凤娇,谢光辉,等.甜高粱生产要素特征、成本及能源效率分析[J].中国农业大学学报,2012,17(6):62-75. |

| HAN L P, MA F J, XIE G H, et al.. Analysis of sweet sorghum’s characteristic of production factor, cost and energy efficiency [J]. J. China Agric. Univ., 2012,17(6): 62-75. | |

| 4 | CAO W X, SUN C, LIU R H, et al.. Comparison of the effects of five pretreatment methods on enhancing the enzymatic digestibility and ethanol production from sweet sorghum bagasse [J]. Bioresour. Technol., 2012, 111: 215-221. |

| 5 | 王家胜,王东伟,尚书旗,等. 4LZZ-1.0型小区稻麦联合收割机的研制及试验[J].农业工程学报,2016,32(18):19-25. |

| WANG J S, WANG D W, SHANG S Q, et al.. Development and experiment on 4LZZ-1.0 type plot grain combine [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(18): 19-25. | |

| 6 | 陈艳普,滕悦江,郭飞扬,等.联合收割机纵轴流脱粒系统研究进展[J].中国农机化学报,2019,40(9):13-19. |

| CHEN Y P, TENG Y J, GUO F Y, et al.. Research progress on longitudinal axial flow threshing system of combine harvester [J]. J. Chin. Agric. Mech., 2019, 40(9): 13-19. | |

| 7 | 孙志强,唐兴隆,贺桂春,等.高粱联合收割机改进试验与研究[J].农业开发与装备,2016(10):104-105. |

| SUN Z Q, TANG X L, HE G C, et al.. Experiment and research on improvement of sorghum combine [J]. Agric. Dev. Equip., 2016(10): 104-105. | |

| 8 | 滕悦江,金诚谦, 陈艳普,等. 稻麦联合收获机分段式脱粒装置设计与优化[J].农业工程学报,2020,36(12): 1-12. |

| TENG Y J, JIN C Q, CHEN Y P, et al.. Design and optimization of segmented threshing device of combine harvester for rice and wheat [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(12): 1-12. | |

| 9 | 梁振伟,李耀明,赵湛,等.纵轴流联合收获机籽粒夹带损失监测方法及传感器研制[J].农业工程学报,2014,30(3):18-26. |

| LIANG Z W, LI Y M, ZHAO Z, et al.. Monitoring method and sensor for grain seoaration loss on axial flow combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(3): 18-26. | |

| 10 | 钟挺,胡志超,顾峰玮,等.4LZ-1.0Q 型稻麦联合收获机脱粒清选部件试验与优化[J].农业机械学报,2012,43(10):76-81. |

| ZHONG T, HU Z C, GU F W, et al.. Optimization and experiment for threshing and cleaning parts of 4LZ-1.0Q cereal combine harvester [J]. Trans. Chin. Soc. Agric. Mach., 2012, 43(10): 76-81. | |

| 11 | 张东明,衣淑娟,陶桂香,等. 谷子轴流脱粒与分离试验台的研制[J].农业化研究,2019, 41(11): 62-67. |

| ZHANG D M, YI S J, TAO G X, et al.. Development of millet axial-flow threshing and separating test bed [J]. J. Agric. Mech. Res., 2019, 41(11): 62-67. | |

| 12 | 徐立章,李耀明,王成红,等.切纵流双滚筒联合收获机脱粒分离装置[J].农业机械学报,2014,45(2):105-108, 135. |

| XU L Z, LI Y M, WANG C H, et al.. A combinational threshing and separating unit of combine harvester with a transverse tangential and an axial rotor [J]. Trans. Chin. Soc. Agric. Mach., 2014, 45(2): 105-108, 135. | |

| 13 | 邸志峰,崔中凯,张华,等. 纹杆块与钉齿组合式轴流玉米脱粒滚筒的设计与试验[J]. 农业工程学报, 2018, 34(1):28-34. |

| DI Z F, CUI Z K, ZHANG H, et al.. Design and experiment of rasp bar and nail tooth combined axial flow corn threshing cylinder [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(1): 28-34. | |

| 14 | 侯守印,陈海涛.立式轴流大豆种子脱粒机参数优化[J].农业工程学报,2012, 28(5): 19-25. |

| HOU S Y, CHEN H T. Parameters optimization of vertical axial flow thresher for soybean breeding [J]. Trans. Chin. Soc. Agric. Eng., 2012, 28(5): 19-25. | |

| 15 | 郝玉伟,段斌,余永昌.室内大豆单株种子脱粒机设计[J].农业工程,2014,4(1):94-97. |

| HAO Y W, DUAN B, YU Y C. Design of indoor thresher for soybean sheller [J]. Agric. Eng., 2014, 4(1): 94-97. | |

| 16 | 李毅念,陈俊生,丁启朔,等.轴流式和切流式机械脱粒对稻谷损伤及加工品质的影响[J].农业工程学报,2017,33(15):41-48. |

| LI Y N, CHEN J S, DING Q S, et al.. Effects of axial flow and tangential flow mechanical threshing on rice damage and milling quality [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(15): 41-48. | |

| 17 | 李耀刚.一种高粱联合收获装置设计与试验[J].农业工程,2017,7(2):118-121. |

| LI Y G. Design and test on a kind of sorghum combined harvesting device [J]. Agric. Eng., 2017, 7(2): 118-121. | |

| 18 | 钱震杰,金诚谦,袁文胜,等. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J].吉林大学学报(工学版),2021,51(3):1121-1130. |

| QIAN Z J, JIN C Q, YUAN W S, et al.. Frictional impact dynamics model of threshing process between flexible teeth and grains [J]. J. Jilin Univ. (Eng. Tech.), 2021,51(3):1121-1130. | |

| 19 | 金诚谦,郭飞扬,徐金山.大豆联合收获机作业参数优化[J].农业工程学报,2019,35(13):10-22. |

| JIN C Q, GUO F Y, XU J S. Optimization of working parameters of soybean combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(13): 10-22. | |

| 20 | 黄小娜,张卫国,党威龙,等.荞麦收获机械研究现状及发展趋势[J].农业机械,2018,850(10):65-71. |

| HUANG X N, ZHANG W G, DANG W L, et al.. Research status and development trend of buckwheat harvesting machinery [J]. Agric. Mach., 2018, 850(10): 154-156. | |

| 21 | 王金双,熊永森,徐中伟,等.纵轴流联合收获机关键部件改进设计与试验[J].农业工程学报,2017,33(10):25-31. |

| WANG J S, XIONG Y S, XU Z W, et al.. Improved design and test of key components for longitudinal axial flow combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(10): 25-31. | |

| 22 | 唐忠,李耀明,梁振伟. 纵轴流脱粒装置水稻最佳脱粒分离参数预测与控制[J]. 农业工程学报,2016,32(22):70-76. |

| TANG Z, LI Y M, LIANG Z W. Optimal parameters prediction and control of rice threshing for longitudinal axial threshing apparatus [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(22): 70-76. | |

| 23 | 邓军,张琦,马兴,等. 脱粒机试验方法: [S].北京:中国标准出版社,2017. |

| 24 | 董殿文, 刘继明, 常智发,等. 高粱: [S]. 北京:中国标准出版社,2007. |

| 25 | 何冯光,邓干然,崔振德,等. 自走式木薯茎叶青贮饲料收获机作业性能研究[J]. 中国农业科技导报,2022,24(8):109-115. |

| HE F G, DENG G R, CUI Z D, et al.. Operating performance of self-propelled silage cassava stem and leaf harvester [J]. J. Agric. Sci. Technol., 2022, 24(8): 109-115. |

| [1] | Manhong WANG, Meijuan XIAO, Ahmad IRSHAD, Eltyb Ahmed Nimir NIMIR, Ibrahim El Dessougi HANADI, Guisheng ZHOU, Guanglong ZHU. Identification and Evaluation of Salt Tolerance in Sorghum at Seedling Stage [J]. Journal of Agricultural Science and Technology, 2025, 27(6): 52-63. |

| [2] | Tingting MA, Yanrong ZHAO, Yuqing WEI, Yuejuan WANG, Xuefei WANG, Erdong ZHANG. Dynamic Characteristics of Stem Growth and Sugar Accumulation of Sweet Sorghum at Late Growth Stage Under Soil Salt Stress [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 42-50. |

| [3] | Yu FENG, Shujin QIU, Xiangyang YUAN, Qingliang CUI, Zhiqiang JI. Research on Compression Mechanical Characteristics of Sorghum Grains [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 102-110. |

| [4] | Zhidan WANG, Jili LIU, Na WU. Effects of Fenlong Tillage on Photosynthetic Physiological Characteristics and Yield of Sweet Sorghum [J]. Journal of Agricultural Science and Technology, 2022, 24(1): 148-156. |

| [5] | CUI Jianghui§, YANG Puyuan§, CHANG Jinhua*. Identification and Expression Analysis Under Abiotic Stress of GRF Gene Family in Sorghum [J]. Journal of Agricultural Science and Technology, 2021, 23(4): 37-46. |

| [6] | WANG Zhiheng, YANG Xiuliu, ZOU Fang, HUANG Siqi, ZHOU Wuyan, XU Zhongwei, WEI Yuqing*. Effects of Salt and Drought Cross Stress on Germination and Physiological Characteristics of Sweet Sorghum Seeds [J]. Journal of Agricultural Science and Technology, 2021, 23(2): 37-49. |

| [7] | FAN Na, PENG Zhidong, BAI Wenbin*, ZHAO Jianwu. Influences of Microbial Agents on Soil Enzyme Activity and Sorghum Growth [J]. Journal of Agricultural Science and Technology, 2021, 23(2): 185-192. |

| [8] | HAO Zhenggang, ZHAO Huijun, WEI Yuqing*, ZENG Zhouqi, WANG Zhiheng. Physiological and Biochemical Responses of Sweet Sorghum to Cadmium Stress and Its Cadmium Accumulation [J]. Journal of Agricultural Science and Technology, 2021, 23(1): 30-42. |

| [9] | WANG Zhiheng, HUANG Siqi, ZOU Fang, YANG Xiuliu, WEI Yuqing*. Effects of Temperature and NaCl on Seed Germination and Seedling Antioxidant Enzyme Activities of Sweet Sorghum [J]. Journal of Agricultural Science and Technology, 2020, 22(9): 42-51. |

| [10] |

ZOU Fang, YANG Xiuliu, HUANG Siqi, WANG Zhiheng, WEI Yuqing*.

Effect of Exogenous Spermine on Growth and Physiological and Biochemical Indexes of Sweet Sorghum Seedlings

under Drought Stress

[J]. Journal of Agricultural Science and Technology, 2020, 22(4): 44-52.

|

| [11] | LIU Chenyang1, ZHANG Huijie2, XIN Xiangfei1*. Analysis of the Development Characteristics and Trends of Sorghum Industry in China [J]. Journal of Agricultural Science and Technology, 2020, 22(10): 1-9. |

| [12] | REN Fuli1,2, PAN Yinghong3, ZHANG Xiaoxiao2, PU Weijun2, MU Yongying3, LI Yubin2, ZHANG Hua1*, ZHU Li2*. Comprehensive Evaluation Method for Sorghum Salt Tolerance Based on Multilevel Phenotypic Analysis [J]. Journal of Agricultural Science and Technology, 2019, 21(6): 152-162. |

| [13] | OU Jiashun1,2, LIU Dawei1,2,3, LI Xu1,2,3, XIE Fangping1,2,3*, WANG Xiushan1,2, XIE Chao1,2. Design and Test of High Self-purification Threshing Device for Small Rice Combine Harvester [J]. Journal of Agricultural Science and Technology, 2017, 19(9): 63-69. |

| [14] | WANG Dong§, WANG Chen§, MA Le, LI Hanxiao, CHEN Jibao*. Establishment of Regeneration System Using Sweet Sorghum Seed as Explant [J]. Journal of Agricultural Science and Technology, 2017, 19(12): 119-125. |

| [15] | LI Xiao-dong, FANG Xian-fa, HAN Zeng-de*, ZHANG Zi-rui, LIU Gui-ming, CUI Jun-we. Dynamic Simulation of Sweet Sorghum Cutting Based on ANSYS/LS-DYNA [J]. , 2015, 17(3): 70-76. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号