中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (9): 131-144.DOI: 10.13304/j.nykjdb.2024.0266

收稿日期:2024-04-02

接受日期:2024-07-02

出版日期:2025-09-15

发布日期:2025-09-24

通讯作者:

宋海潮

作者简介:代祥 E-mail: 18852089528@139.com;

基金资助:

Xiang DAI1,2( ), Haichao SONG1(

), Haichao SONG1( ), Chuan SU1

), Chuan SU1

Received:2024-04-02

Accepted:2024-07-02

Online:2025-09-15

Published:2025-09-24

Contact:

Haichao SONG

摘要:

针对当前大蒜种植机械化程度低的现状,设计了一款自走式大蒜正芽播种施肥一体化机具,并进行了初步的田间试验。机具采用链勺方式实现大蒜单粒取种和输送,采用平行四连杆和双鸭嘴结构实现正芽栽植,采用外槽轮排肥器实现肥料供给,基于液压装置实现后尾架及其附属单粒取种和正芽栽植系统举升,满足运输和播施状态切换,并具有机具原位调头能力。在大蒜种植株距为120 mm,正芽栽植器周向安装6只插播鸭嘴条件下,确定栽植圆盘半径为162.5 mm,并据此设计鸭嘴打开圆盘边缘曲线;基于ANSYS Workbench,在评估机架静力学、模态及频率响应的基础上对机架和后尾架组合体进行型材优选,实现结构性能提升和减重。田间试验结果表明,机具整体上适宜播种深度约为6 cm,不宜将其用于较浅深度下的播种作业;播种深度为6 cm条件下,播种速度高于15 m·min-1时重播率低于3.0%,播种速度大于18 m·min-1时漏播率高于5%,机具适宜播种速度约15 m·min-1;此时,对应机具播种正芽率高于85%,播深合格率高于90%,能有效保证符合深度的大蒜正芽栽植;较大的预设施肥深度能够取得更高的施肥稳定系数,当施肥深度大于5 cm时,施肥稳定系数接近0.95,施肥稳定性较好。整机在播施功能的实现上达到了预定要求。

中图分类号:

代祥, 宋海潮, 苏川. 自走式大蒜正芽播种施肥机设计与试验[J]. 中国农业科技导报, 2025, 27(9): 131-144.

Xiang DAI, Haichao SONG, Chuan SU. Design and Experiment of Self-propelled Garlic Vertically-planting and Fertilizing Integrated Machine[J]. Journal of Agricultural Science and Technology, 2025, 27(9): 131-144.

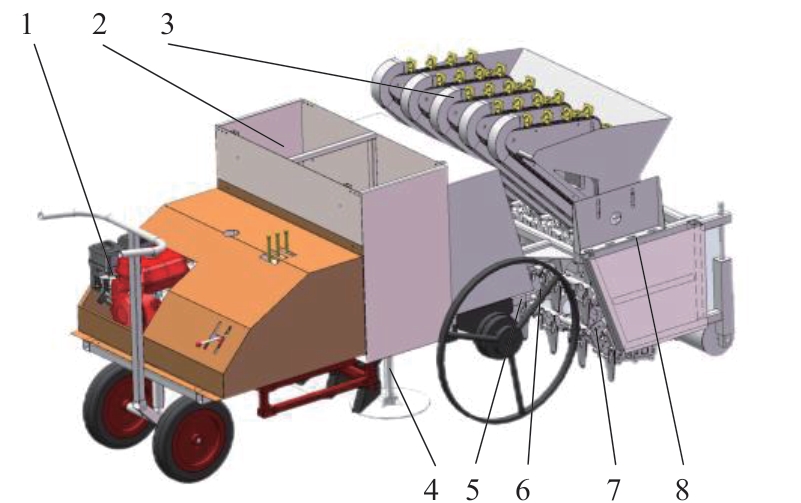

图1 整机结构及虚拟样机模型注:1—动力系统;2—自动施肥系统;3—单粒取种系统;4—液压系统;5—机架;6—自动施药系统;7—正芽栽植系统;8—后尾架。

Fig. 1 Overall structure diagram and the virtual prototypeNote: 1—Power system; 2—Automatic fertilization system; 3—Single-seed fetching system; 4—Hydraulic system; 5—Frame; 6—Automatic pesticide spraying system; 7—Vertically-planting system; 8—Tailstock frame.

| 参数 Parameter | 数值 Value |

|---|---|

| 整机尺寸Overall size/mm | 2 360×1 150×1 050 |

| 播种行数Number of seeded rows | 5 |

| 施肥行数Number of fertilization rows | 4 |

| 播种行距Seeding row spacing/mm | 180 |

| 标准株距Standard plant spacing (DP)/mm | 120 |

| 理论播种速度Theoretical seeding rate(Vb) /(m·min-1) | 10~20 |

| 理论播种深度Theoretical seeding depth/cm | <6 |

| 作业生产率Working productivity | 0.08 |

| 施肥深度Fertilization depth/cm | <6 |

| 施药喷头数Number of nozzles | 2 |

表1 机具技术参数

Table 1 Technical parameters for the prototype

| 参数 Parameter | 数值 Value |

|---|---|

| 整机尺寸Overall size/mm | 2 360×1 150×1 050 |

| 播种行数Number of seeded rows | 5 |

| 施肥行数Number of fertilization rows | 4 |

| 播种行距Seeding row spacing/mm | 180 |

| 标准株距Standard plant spacing (DP)/mm | 120 |

| 理论播种速度Theoretical seeding rate(Vb) /(m·min-1) | 10~20 |

| 理论播种深度Theoretical seeding depth/cm | <6 |

| 作业生产率Working productivity | 0.08 |

| 施肥深度Fertilization depth/cm | <6 |

| 施药喷头数Number of nozzles | 2 |

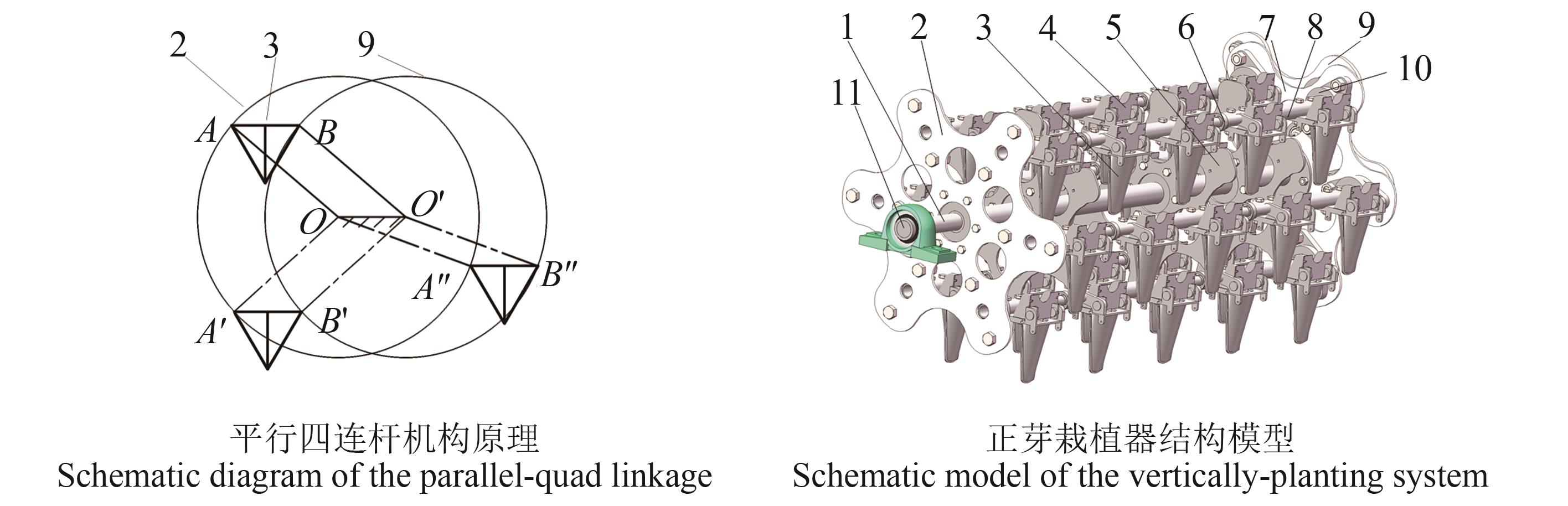

图3 正芽栽植系统注:1—正芽栽植动力主轴;2, 7—第1栽植圆盘;3—插播鸭嘴;4—接种鸭嘴打开器;5—鸭嘴打开圆盘;6—鸭嘴打开轴承;8—鸭嘴安装曲轴;9—第2栽植圆盘;10—曲轴回转轴承;11—栽植器安装轴承。

Fig. 3 Vertically-planting systemNote:1—Power shaft of the system; 2, 7—The first planting disc; 3—Insert duck bills; 4—Inoculate duckbill opening disc; 5—Opener disc for duckbill; 6—Duckbill opening disc bearing; 8—Duckbill mounted crankshaft; 9—The second planting disc; 10—Crankshaft slewing bearing; 11—Planter mounted bearings.

图4 插播鸭嘴及鸭嘴打开圆盘的设计过程注:1—鸭嘴活动部分;2—鸭嘴固定部分;3—鸭嘴打开轴承;4—鸭嘴打开圆盘;5—曲轴回转轴承;6—鸭嘴安装曲轴;7—第1栽植圆盘。

Fig. 4 Plant duckbills and the design process of the disc type duckbill openerNote:1—Moving part of duckbill; 2—Static part of duckbill; 3—Duckbill opening bearing; 4—Duckbill opening disc; 5—Crankshaft slewing bearing; 6—Duckbill mounted crankshaft; 7—The first planting disc.

序号 Action phase | 鸭嘴整体位置 Position of duckbill | 鸭嘴打开轴承相对位置 Position of duckbill opening disc bearing | 鸭嘴状态 Status of duckbill | 对应边缘曲线 Corresponding edge curve |

|---|---|---|---|---|

| Ⅰ | 最低端逐步上移 Moving up from the bottom | 从C点运动至D点 From position C to D | 鸭嘴逐步打开 Duckbill opening gradually | d2~d3 |

| Ⅱ | 逐步上移 Moving up | D点 Position D | 鸭嘴完全打开 Duckbill opened completely | d3~d4 |

| Ⅲ | 逐步上移 Moving up | 从D点运动至C点 From position D to C | 鸭嘴逐步关闭 Duckbill closing gradually | d4~d5 |

| Ⅳ | 逐步运动至最低端 Cycle to the very bottom | C点 Position C | 鸭嘴完全关闭 Duckbill closed completely | d5~d6~d7~d1 |

表2 插播鸭嘴动作时序表

Table 2 Action timing table for duckbill

序号 Action phase | 鸭嘴整体位置 Position of duckbill | 鸭嘴打开轴承相对位置 Position of duckbill opening disc bearing | 鸭嘴状态 Status of duckbill | 对应边缘曲线 Corresponding edge curve |

|---|---|---|---|---|

| Ⅰ | 最低端逐步上移 Moving up from the bottom | 从C点运动至D点 From position C to D | 鸭嘴逐步打开 Duckbill opening gradually | d2~d3 |

| Ⅱ | 逐步上移 Moving up | D点 Position D | 鸭嘴完全打开 Duckbill opened completely | d3~d4 |

| Ⅲ | 逐步上移 Moving up | 从D点运动至C点 From position D to C | 鸭嘴逐步关闭 Duckbill closing gradually | d4~d5 |

| Ⅳ | 逐步运动至最低端 Cycle to the very bottom | C点 Position C | 鸭嘴完全关闭 Duckbill closed completely | d5~d6~d7~d1 |

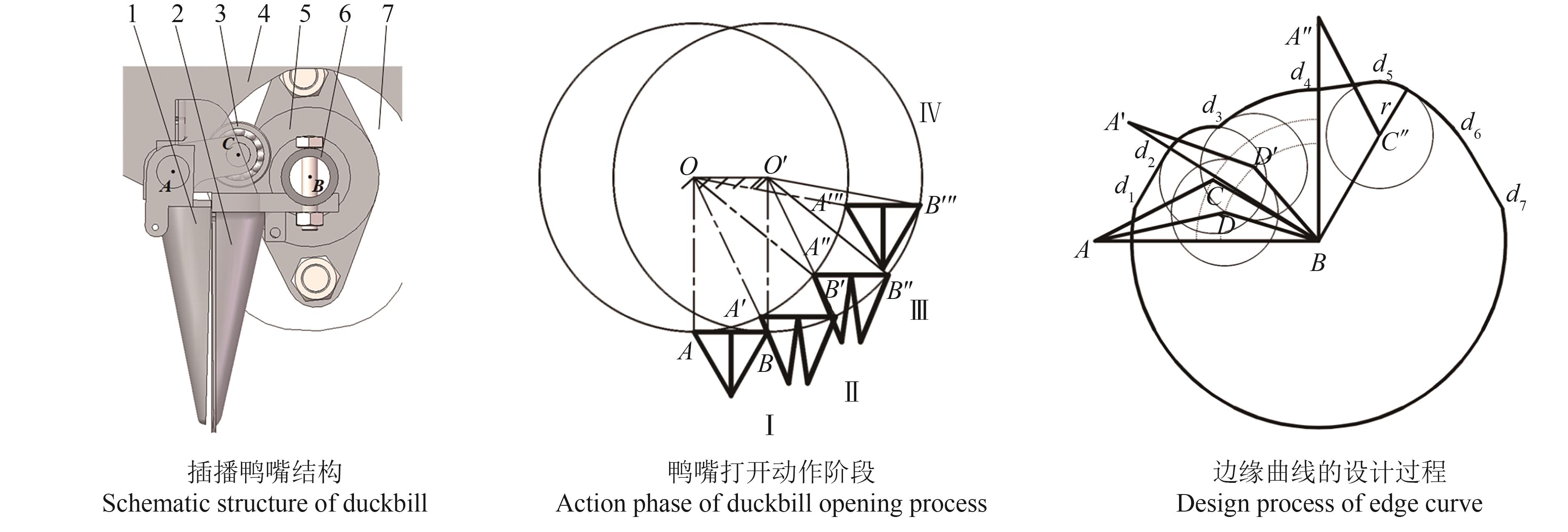

图5 种箱和单粒取种机构注:1—蒜种护筒;2—第3链轮;3—取种链条;4—种勺;5—蒜箱;6—第2链轮;7—第1链轮;8—种槽;9—防漏筒;10—安装支架。

Fig. 5 Schematic diagram of the garlic storage tank and the single-garlic picking mechanismNote: 1—Garlic seed guard; 2—The third sprocket; 3—Seed chain; 4—Seed spoon; 5—Garlic box; 6—The second sprocket; 7—The first sprocket; 8—Seed groove; 9—Leak-proof cylinder; 10—Mounting bracket.

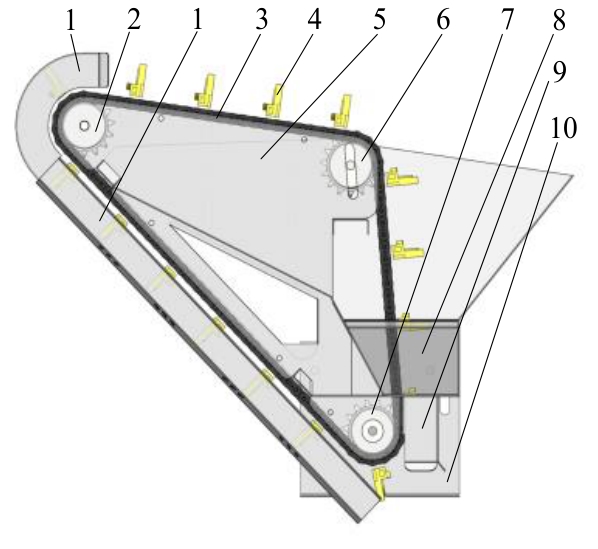

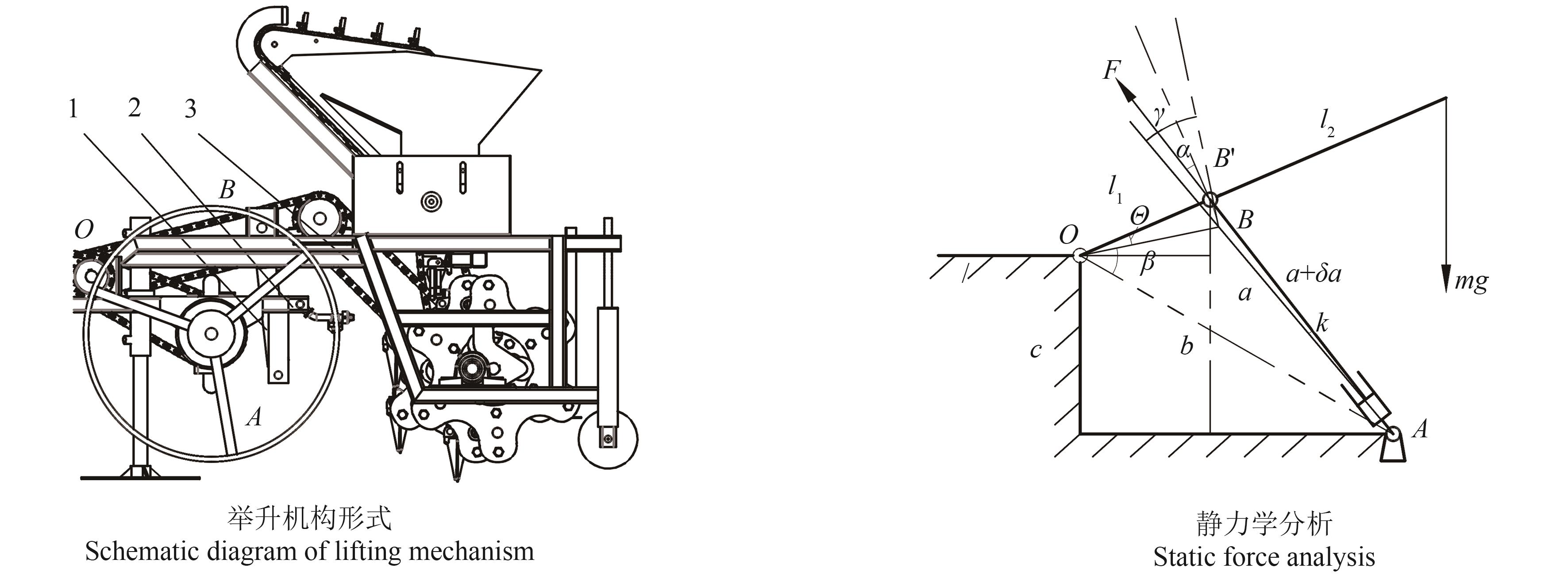

图6 举升机构形式及其受力分析注:1—机架;2—后尾架举升液压缸;3—后尾架。

Fig. 6 Schematic diagram of lifting mechanism and force analysisNote:1—Frame; 2—Tailstock frame lifting Hydraulic cylinders; 3—Tailstock frame.

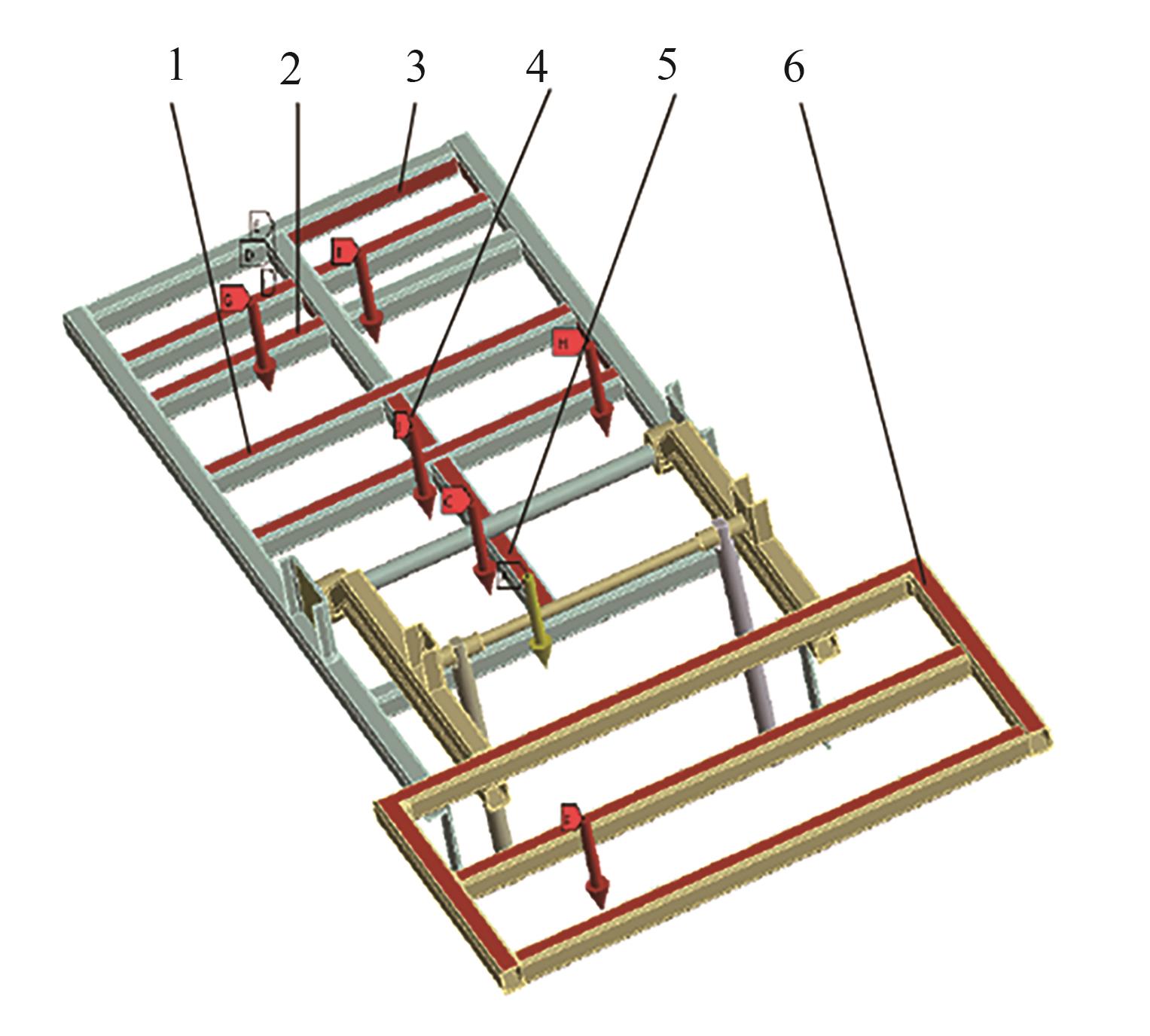

图7 机架和后尾架组合体载荷和约束注:1—施肥系统承力点;2—变速箱和液压源承力点;3—发动机和减速箱承力点;4—大液压缸承力点;5—施药系统承力点;6—种箱和单粒取种机构以及正芽栽植系统承力点。

Fig. 7 Loads and constraints of rear tailstock assemblyNote: 1—Bearing position of fertilization system; 2—Bearing position of gearbox and hydraulic source; 3—Bearing position of engine and reducer; 4—Bearing position of main hydraulic cylinder; 5—Bearing position of pesticide application system; 6—Bearing position of storage tank, single-seed fetching and vertically-planting system.

水平 Level | 因素Factor | |

|---|---|---|

| A:播种速度Seeding speed/(m·min-1) | B:播种深度Seeding depth/cm | |

| 1 | 12 | 4 |

| 2 | 15 | 5 |

| 3 | 18 | 6 |

表3 多因素正芽栽植试验设计

Table 3 Design of multifactor positive bud planting experiment

水平 Level | 因素Factor | |

|---|---|---|

| A:播种速度Seeding speed/(m·min-1) | B:播种深度Seeding depth/cm | |

| 1 | 12 | 4 |

| 2 | 15 | 5 |

| 3 | 18 | 6 |

| 编号NO. | 钢材型号(高×宽×厚)[ Steel type (height×width×thickness)/mm[ | 最大等效应力 Maximum equivalent stress/MPa | 1阶固有频率Natural frequency of the 1st order/Hz | 2阶固有频率Natural frequency of the 2nd order/Hz | 3阶固有频率Natural frequency of the 3rd order/Hz | 4阶固有频率Natural frequency of the 4th order/Hz | 5阶固有频率Natural frequency of the 5th order/Hz | 6阶固有频率Natural frequency of the 6th order/Hz | 机架和后尾架合计质量Total mass of frame and tailstock frame/kg | |

|---|---|---|---|---|---|---|---|---|---|---|

机架 Frame | 后尾架Tailstock frame | |||||||||

| 1 | 40×40×3 | 40×40×3 | 563.10 | 14.36 | 28.55 | 33.52 | 46.46 | 61.00 | 65.14 | 61.44 |

| 2 | 40×40×4 | 40×40×3 | 308.20 | 18.23 | 27.44 | 38.96 | 55.05 | 66.75 | 68.97 | 69.68 |

| 3 | 40×40×4 | 40×40×4 | 281.40 | 13.57 | 17.22 | 36.68 | 58.97 | 60.24 | 86.20 | 75.29 |

| 4 | 50×50×4 | 50×50×3 | 273.50 | 12.52 | 16.58 | 34.53 | 57.68 | 61.23 | 79.65 | 86.15 |

| 5 | 50×50×4 | 50×50×4 | 259.23 | 11.71 | 16.75 | 33.95 | 59.63 | 62.34 | 82.34 | 93.69 |

表4 不同结构尺寸机架和后尾架组合体导致的机架最大等效应力和固有频率

Table 4 Maximum equivalent stress and natural frequencies caused by the structure of frame and rear tailstock assembly of differing structural sizes

| 编号NO. | 钢材型号(高×宽×厚)[ Steel type (height×width×thickness)/mm[ | 最大等效应力 Maximum equivalent stress/MPa | 1阶固有频率Natural frequency of the 1st order/Hz | 2阶固有频率Natural frequency of the 2nd order/Hz | 3阶固有频率Natural frequency of the 3rd order/Hz | 4阶固有频率Natural frequency of the 4th order/Hz | 5阶固有频率Natural frequency of the 5th order/Hz | 6阶固有频率Natural frequency of the 6th order/Hz | 机架和后尾架合计质量Total mass of frame and tailstock frame/kg | |

|---|---|---|---|---|---|---|---|---|---|---|

机架 Frame | 后尾架Tailstock frame | |||||||||

| 1 | 40×40×3 | 40×40×3 | 563.10 | 14.36 | 28.55 | 33.52 | 46.46 | 61.00 | 65.14 | 61.44 |

| 2 | 40×40×4 | 40×40×3 | 308.20 | 18.23 | 27.44 | 38.96 | 55.05 | 66.75 | 68.97 | 69.68 |

| 3 | 40×40×4 | 40×40×4 | 281.40 | 13.57 | 17.22 | 36.68 | 58.97 | 60.24 | 86.20 | 75.29 |

| 4 | 50×50×4 | 50×50×3 | 273.50 | 12.52 | 16.58 | 34.53 | 57.68 | 61.23 | 79.65 | 86.15 |

| 5 | 50×50×4 | 50×50×4 | 259.23 | 11.71 | 16.75 | 33.95 | 59.63 | 62.34 | 82.34 | 93.69 |

| 机具行进速度Prototype moving speed/(m·min-1) | 取种速度/(株·s-1) Seeds fetching speed/(plant·s-1) | 播种深度 Seeding depth/cm | 重播率PC/% | 漏播率PL/% | 合格率PH/% | 正芽率PZ/% | 播深合格率PS/% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | F | S | F | S | F | S | F | S | F | |||

| 12 | 1.67 | 4 | 5.6 | 3.8 | 6.0 | 7.8 | 88.4 | 88.4 | — | 80.7 | — | 86.6 |

| 12 | 1.67 | 5 | 6.8 | 4.6 | 4.2 | 6.2 | 89.0 | 89.2 | — | 84.5 | — | 92.5 |

| 12 | 1.67 | 6 | 7.2 | 5.3 | 2.2 | 3.5 | 90.6 | 91.2 | — | 86.6 | — | 93.5 |

| 15 | 2.08 | 4 | 4.1 | 2.7 | 5.9 | 8.5 | 90.0 | 88.8 | — | 79.4 | — | 90.6 |

| 15 | 2.08 | 5 | 5.0 | 2.6 | 3.4 | 6.9 | 91.6 | 90.5 | — | 84.3 | — | 91.4 |

| 15 | 2.08 | 6 | 5.2 | 3.0 | 2.5 | 4.0 | 92.3 | 93.0 | — | 85.3 | — | 92.8 |

| 18 | 2.50 | 4 | 2.8 | 2.0 | 9.4 | 10.8 | 87.8 | 87.2 | — | 80.2 | — | 91.3 |

| 18 | 2.50 | 5 | 3.9 | 2.2 | 5.9 | 7.5 | 90.2 | 90.3 | — | 84.0 | — | 92.1 |

| 18 | 2.50 | 6 | 4.3 | 2.5 | 3.1 | 5.1 | 92.6 | 92.4 | — | 84.8 | — | 92.5 |

表5 不同播种速度下试验结果

Table 5 Test results at different drilling rates

| 机具行进速度Prototype moving speed/(m·min-1) | 取种速度/(株·s-1) Seeds fetching speed/(plant·s-1) | 播种深度 Seeding depth/cm | 重播率PC/% | 漏播率PL/% | 合格率PH/% | 正芽率PZ/% | 播深合格率PS/% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | F | S | F | S | F | S | F | S | F | |||

| 12 | 1.67 | 4 | 5.6 | 3.8 | 6.0 | 7.8 | 88.4 | 88.4 | — | 80.7 | — | 86.6 |

| 12 | 1.67 | 5 | 6.8 | 4.6 | 4.2 | 6.2 | 89.0 | 89.2 | — | 84.5 | — | 92.5 |

| 12 | 1.67 | 6 | 7.2 | 5.3 | 2.2 | 3.5 | 90.6 | 91.2 | — | 86.6 | — | 93.5 |

| 15 | 2.08 | 4 | 4.1 | 2.7 | 5.9 | 8.5 | 90.0 | 88.8 | — | 79.4 | — | 90.6 |

| 15 | 2.08 | 5 | 5.0 | 2.6 | 3.4 | 6.9 | 91.6 | 90.5 | — | 84.3 | — | 91.4 |

| 15 | 2.08 | 6 | 5.2 | 3.0 | 2.5 | 4.0 | 92.3 | 93.0 | — | 85.3 | — | 92.8 |

| 18 | 2.50 | 4 | 2.8 | 2.0 | 9.4 | 10.8 | 87.8 | 87.2 | — | 80.2 | — | 91.3 |

| 18 | 2.50 | 5 | 3.9 | 2.2 | 5.9 | 7.5 | 90.2 | 90.3 | — | 84.0 | — | 92.1 |

| 18 | 2.50 | 6 | 4.3 | 2.5 | 3.1 | 5.1 | 92.6 | 92.4 | — | 84.8 | — | 92.5 |

| [1] | 柳平增, 张艳, 张超, 等. 我国大蒜市场与产业调查分析报告[J]. 农产品市场, 2021(11): 55-56. |

| [2] | 孔素萍, 孙敬强, 吴雄, 等. 大蒜主要农艺性状变异特征及其与产量相关构成分析[J]. 中国农业科学, 2015, 48(6): 1240-1248. |

| KONG S P, SUN J Q, WU X, et al.. Analysis of relationship between variations of main agronomic traits and yield in garlic [J]. Sci. Agric. Sin., 2015, 48(6): 1240-1248. | |

| [3] | 崔荣江, 黄嘉宝, 张振河, 等. 大蒜机械化播种技术研究现状[J]. 农业装备与车辆工程, 2018, 56(6): 54-56. |

| CUI R J, HUANG J B, ZHANG Z H, et al.. Research status of garlic mechanized sowing technology [J]. Agric. Equip. Veh. Eng., 2018, 56(6): 54-56. | |

| [4] | 代祥, 宋海潮, 于林惠, 等. 自走式大蒜播种施肥一体机优化设计与试验[J]. 中国农机化学报, 2023, 44(7): 16-25. |

| DAI X, SONG H C, YU L H, et al.. Optimized design and experiment of the self-propelled garlic drilling and fertilizing integrated machine [J]. J. Chin. Agric. Mech., 2023, 44(7): 16-25. | |

| [5] | 信嘉程. 基于视觉识别的大蒜正芽机构设计与试验研究[D]. 杭州: 浙江理工大学, 2023. |

| XIN J C. Design and experimental study of positive bud garlic mechanism based on visual recognition [D]. Hangzhou: Zhejiang Sci-Tech University, 2023. | |

| [6] | 栗晓宇. 大蒜播种关键技术与装置的研究[D]. 泰安: 山东农业大学, 2019. |

| LI X Y. Research on key technologies and devices of garlic planting [D]. Tai’an: Shandong Agriculture University, 2022. | |

| [7] | 田林. 基于图像识别技术的蒜种定向装置设计与试验[D]. 泰安: 山东农业大学, 2020. |

| TIAN L. Design and experiment of garlic seed orientation device based on image recognition technology [D]. Tai’an: Shandong Agriculture University, 2020. | |

| [8] | 荐世春, 刘云东. 大蒜播种机蒜瓣自动定向控制装置的试验研究[J]. 农业装备与车辆工程, 2009, 47(10): 28-29, 37. |

| JIAN S C, LIU Y D. Experimental research on the garlic clove automatic orientation control device of garlic planting machine [J]. Agric. Equip. Veh. Eng., 2009, 47(10): 28-29, 37. | |

| [9] | 张欣艳. 勺夹式大蒜精量播种装置作用机理与参数试验研究[D]. 大庆: 黑龙江八一农垦大学, 2022. |

| ZHANG X Y. Experimental study on mechanism and parameters of key components of spoon-clip garlic precision seeding device [D]. Daqing: Heilongjiang Bayi Agricultural University, 2022. | |

| [10] | 唐通鸣, 邹帅, 刘勇兰, 等. 振动筛排种器在大蒜播种机中的应用[J]. 农机化研究, 2015, 37(12): 92-96. |

| TANG T M, ZOU S, LIU Y L, et al.. The application of vibration sieve and metering device in the garlic seeder upright screening device [J]. J. Agric. Mech. Res., 2015, 37(12): 92-96. | |

| [11] | 耿爱军, 栗晓宇, 侯加林, 等. 自动定向大蒜播种机的设计与试验[J]. 农业工程学报, 2018, 34(11): 17-25. |

| GENG A J, LI X Y, HOU J L, et al.. Design and experiment of automatic directing garlic planter [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(11): 17-25. | |

| [12] | 李天华, 黄圣海, 牛子孺, 等. 行星轮式大蒜插播机播种直立度优化与试验[J]. 农业工程学报, 2020, 36(3): 37-45. |

| LI T H, HUANG S H, NIU Z R, et al.. Optimization and experiment of planting perpendicularity of planetary wheel garlic planter [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(3): 37-45. | |

| [13] | 栗晓宇, 耿爱军, 侯加林, 等. 全自动蒜种盒提取投放装置设计与试验[J]. 农业工程学报, 2017, 33(23): 32-37. |

| LI X Y, GENG A J, HOU J L, et al.. Design and experiment of full-automatic lifting and releasing device of garlic seed box [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(23): 32-37. | |

| [14] | 崔荣江, 王小瑜, 信嘉程, 等. 弧形鸭嘴式大蒜正芽播种机设计与试验[J]. 农业机械学报, 2022, 53(11): 120-130. |

| CUI R J, WANG X Y, XIN J C, et al.. Design and test of arc duck-billed garlic seed planter [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(11): 120-130. | |

| [15] | 谢东波. 扰种齿辅助气吸式大蒜排种器设计与试验[D]. 合肥: 安徽农业大学, 2021. |

| XIE D B. Design and test of garlic seed placer with seed disturbing tooth assisted air suction [D]. Hefei: Anhui Agricultural University, 2022. | |

| [16] | DING Y G, LI H, GAO J F, et al.. Parameter optimization of finger clip plate garlic seed-metering device [J/OL]. Agriculture, 2023, 13(11): 2071 [2024-03-03]. . |

| [17] | 崔荣江, 辛丽, 朱月浩, 等. 一种自走式大蒜播种机械设备: CN215073870U[P]. 2021-12-10. |

| [18] | 郭佳皓. 山东大蒜主产区全程机械化生产效率调查研究[D]. 保定: 河北农业大学, 2021. |

| GUO J H. Investigation and study on the whole mechanized operation efficiency in garlic producing areas of Shandong province [D]. Baoding: Hebei Agriculture University, 2020. | |

| [19] | 金文忻, 刘永华, 张东凤, 等. 大蒜直立种植装置设计与试验[J]. 中国农机化学报, 2020, 41(6): 37-42. |

| JIN W X, LIU Y H, ZHANG D F, et al.. Design and test of vertical planting device for garlic [J]. J. Chin. Agric. Mech., 2020, 41(6): 37-42. | |

| [20] | 侯加林, 黄圣海, 牛子孺, 等. 双鸭嘴式大蒜正头装置调头机理分析与试验[J]. 农业机械学报, 2018, 49(11): 87-96. |

| HOU J L, HUANG S H, NIU Z R, et al.. Mechanism analysis and test of adjusting garlics upwards using two duckbill devices [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(11): 87-96. | |

| [21] | 李天华, 张海阔, 韩相龙, 等. 勺链式大蒜播种机漏取种检测与补种装置设计及试验[J]. 农业工程学报, 2022, 38(4): 24-32. |

| LI T H, ZHANG H K, HAN X L, et al.. Design and experiment of missing seed detection and the reseeding device for spoon chain garlic seeders [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(4): 24-32. | |

| [22] | 刘泽松, 王浩屹, 李骅, 等. 基于有限元的大蒜播种机机架轻量化设计[J]. 中国农机化学报, 2022, 43(1): 27-32. |

| LIU Z S, WANG H Y, LI H, et al.. Lightweight design of a garlic planter frame based on finite element method [J]. J. Chin. Agric. Mech., 2022, 43(1): 27-32. | |

| [23] | 钱伟中, 王大齐, 朱少文, 等. 结构用冷弯空心型钢尺寸、外形、重量及允许偏差: [S]. 北京: 中国标准出版社, 2002. |

| [24] | 杨兆文, 刘星福, 李问盈. 单粒(精密)播种机试验方法: [S]. 北京: 中国标准出版社, 2005. |

| [25] | 栗慧卿, 王永建, 崇峻, 等. 大蒜播种机 通用技术规范: [S]. 北京: 中国标准出版社, 2019. |

| [1] | 胡华鹏, 张绪坤, 谌佳君, 潘杨杨, 杨佩林, 鲁志. 茶渣双轴搅拌干燥机结构优化及含水率模拟分析[J]. 中国农业科技导报, 2025, 27(4): 120-132. |

| [2] | 沈乐丞, 温志刚, 廖涵, 刘贤标, 蒋耀聪, 张远聪, 刘婷, 王玫. 叶面喷施不同硒肥对水稻硒含量及硒形态和稻米组分的影响[J]. 中国农业科技导报, 2025, 27(3): 206-215. |

| [3] | 高阳, 李粤, 位士全, 黄椿, 吴紫晗, 魏晨辉, 黄麒润. 具有腐熟剂喷施装置的香蕉秸秆粉碎还田机的设计与试验[J]. 中国农业科技导报, 2024, 26(9): 93-104. |

| [4] | 黄椿, 李粤, 位士全, 高阳, 吴紫晗, 黄麒润, 魏晨辉. 异向双轴香蕉秸秆粉碎还田机设计与试验[J]. 中国农业科技导报, 2024, 26(11): 97-106. |

| [5] | 陈子民, 莫江婷, 陈广生, 郭小璇, 朱贤文. 基于Fluent的顶风式热泵干燥箱气流场分析及优化[J]. 中国农业科技导报, 2024, 26(10): 135-144. |

| [6] | 石婷婷, 廖宇兰, 彭绪友, 袁成宇. 单行直插式木薯种植机的设计与优化[J]. 中国农业科技导报, 2022, 24(6): 115-122. |

| [7] | 潘梦诗, 郭文阳, 周留柱, 邓丽, 苗建利, 徐宏光, 张宗源, 亓兰达. 贝莱斯芽孢杆菌菌剂对花生白绢病的田间防效及作用机理研究[J]. 中国农业科技导报, 2022, 24(11): 130-136. |

| [8] | 郭文斌, 李瑶, 黄长华, 杜建强, 钱珊珠, 何泽民, 高晶晶. 基于COMSOL的干燥箱物理场分析与结构优化[J]. 中国农业科技导报, 2022, 24(10): 90-98. |

| [9] | 宋海潮1,2,徐幼林2*,郑加强2,代祥2. 旋动射流混药器螺旋弯曲收缩管螺距和分流器位置的模拟优化分析[J]. 中国农业科技导报, 2019, 21(9): 84-89. |

| [10] | 谢超1,刘大为1,2,李旭1,2,谢方平1,2*,王勋威1,谢锦帆1. 小型水稻联合收割机旋风分离清选装置的结构优化与试验[J]. 中国农业科技导报, 2018, 20(5): 54-63. |

| [11] | 刘东,肖宏儒*,金月,杨光. 基于ANSYS的鸡毛菜茎秆切割的有限元分析及验证试验[J]. 中国农业科技导报, 2018, 20(11): 85-93. |

| [12] | 温晓霞 廖允成 等. 宁南旱作农区种植业结构调整研究[J]. , 2002, 4(6): 28-31. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||