中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (10): 126-136.DOI: 10.13304/j.nykjdb.2022.0389

收稿日期:2022-05-10

接受日期:2022-09-06

出版日期:2023-10-15

发布日期:2023-10-27

通讯作者:

彭才望

作者简介:周婷 E-mail:760399822@qq.com;

基金资助:

Ting ZHOU( ), Songlin SUN, Haiying ZHU, Caiwang PENG(

), Songlin SUN, Haiying ZHU, Caiwang PENG( )

)

Received:2022-05-10

Accepted:2022-09-06

Online:2023-10-15

Published:2023-10-27

Contact:

Caiwang PENG

摘要:

黑水虻生物转化猪粪后获得的有机肥含水率介于40%~60%之间,其黏结流动参数难以通过常规手段获取。为探究含水率对有机肥黏结流动的影响,通过堆积角测定与离散元仿真相结合的方法,从数值上量化分析不同含水率(41.21%~60.52%)对有机肥颗粒流动与黏结能力的影响。结果表明,有机肥-不锈钢碰撞恢复系数、有机肥-不锈钢静摩擦系数、有机肥JKR(Johnson-Kendall-Roberts)表面能显著影响有机肥堆积角;有机肥含水率在41.21%~60.52%范围内,随着含水率的增加,有机肥-不锈钢静摩擦系数先增大后减小,在含水率56.56%时达到最大值,为0.39,而JKR表面能由0.22 J·m-2逐渐升高到0.47 J·m-2;有机肥直剪试验表明,当含水率大于40%时,有机肥颗粒间的内摩擦角逐渐减小,但颗粒间的内聚力随JKR表面能增大而增大,有机肥颗粒间易发生团聚现象,一定程度上阻碍颗粒流动,堆积角增大。研究结果可为转移、输送有机肥的机械设备研究提供基础数据支撑。

中图分类号:

周婷, 孙松林, 朱海英, 彭才望. 含水率对黑水虻生物转化猪粪有机肥黏结流动的影响[J]. 中国农业科技导报, 2023, 25(10): 126-136.

Ting ZHOU, Songlin SUN, Haiying ZHU, Caiwang PENG. Effect of Moisture Content on Bond Flows of Black Soldier Fly Larvae Biotransformation Pig Manure Organic Fertilizer[J]. Journal of Agricultural Science and Technology, 2023, 25(10): 126-136.

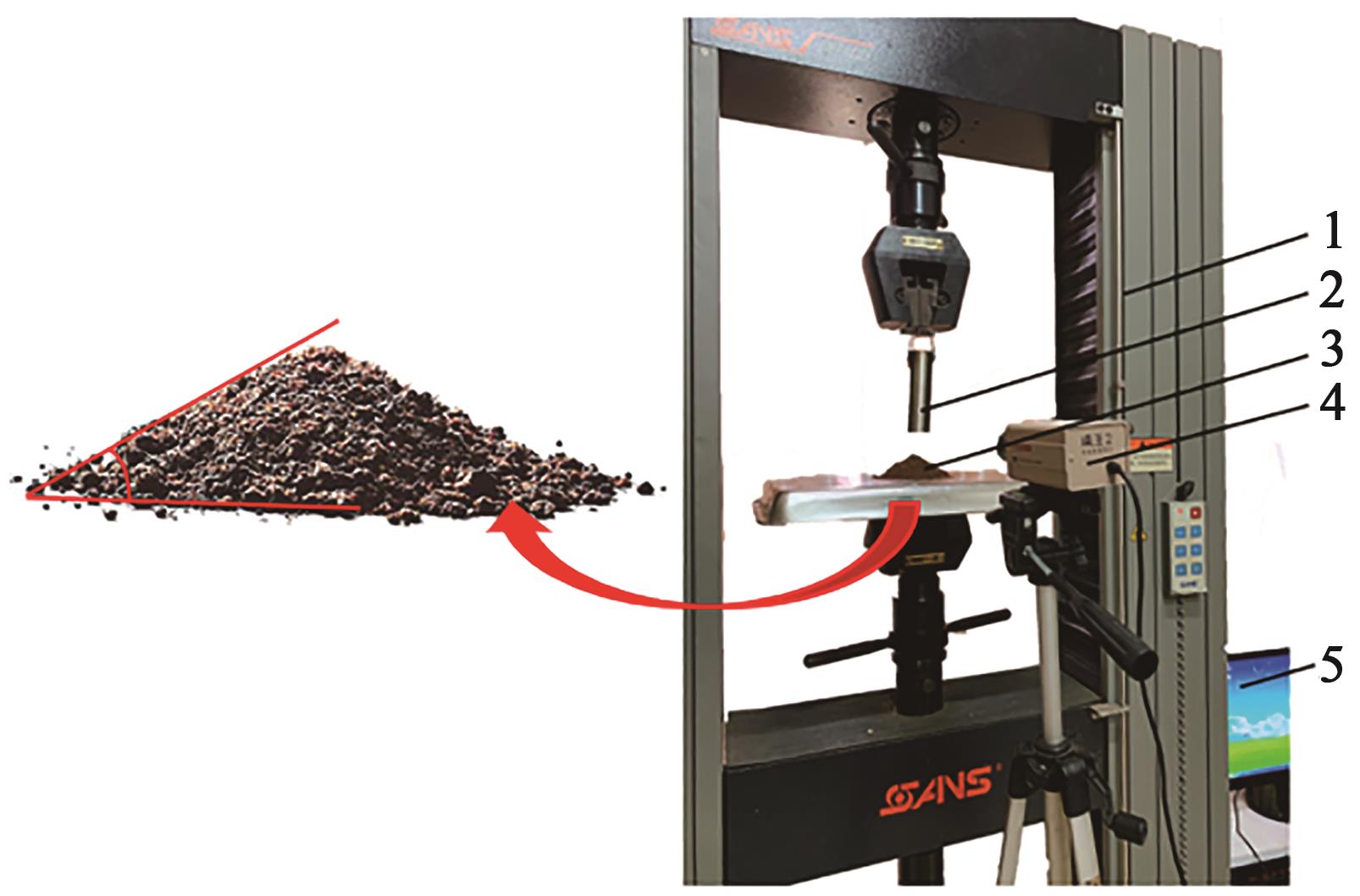

图1 有机肥堆积试验注:1—万能试验机;2—钢质圆筒;3—肥堆;4—摄像机;5—计算机。

Fig. 1 Repose angle of organic fertilizerNote:1—Universal testing machine; 2—Steel cylinder;3—Fertilizer heap;4—Video camera;5—Computer.

参数符号 Parameter notation | 参数 Parameter | 参数水平 Parameter level | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| T1 | 泊松比Poisson ratio | 0.10 | 0.30 | 0.50 |

| T2 | 剪切模量Shear modulus/MPa | 1.00 | 5.50 | 10.00 |

| T3 | 密度Particle density/(kg·m-3) | 1 600 | 2 000 | 2 400 |

| T4 | 有机肥-有机肥碰撞恢复系数 Organic fertilizer-organic fertilizer collided restitution coefficient | 0.40 | 0.60 | 0.80 |

| T5 | 有机肥-有机肥静摩擦系数 Organic fertilizer-organic fertilizer static friction coefficient | 0.10 | 0.55 | 1.00 |

| T6 | 有机肥-有机肥滚动摩擦系数 Organic fertilizer-organic fertilizer rolling friction coefficient | 0.05 | 0.25 | 0.45 |

| T7 | 有机肥-不锈钢碰撞恢复系数 Organic fertilizer-steel collided restitution coefficient | 0.15 | 0.40 | 0.65 |

| T8 | 有机肥-不锈钢静摩擦系数 Organic fertilizer-steel static friction coefficient | 0.10 | 0.50 | 0.90 |

| T9 | 有机肥-不锈钢滚动摩擦系数 Organic fertilizer-steelr rolling friction coefficient | 0.10 | 0.40 | 0.70 |

| T10 | JKR表面能JKR surface energy/(J·m-2) | 0.05 | 0.40 | 0.75 |

表1 离散元仿真标定参数

Table 1 Parameters required for discrete element simulation

参数符号 Parameter notation | 参数 Parameter | 参数水平 Parameter level | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| T1 | 泊松比Poisson ratio | 0.10 | 0.30 | 0.50 |

| T2 | 剪切模量Shear modulus/MPa | 1.00 | 5.50 | 10.00 |

| T3 | 密度Particle density/(kg·m-3) | 1 600 | 2 000 | 2 400 |

| T4 | 有机肥-有机肥碰撞恢复系数 Organic fertilizer-organic fertilizer collided restitution coefficient | 0.40 | 0.60 | 0.80 |

| T5 | 有机肥-有机肥静摩擦系数 Organic fertilizer-organic fertilizer static friction coefficient | 0.10 | 0.55 | 1.00 |

| T6 | 有机肥-有机肥滚动摩擦系数 Organic fertilizer-organic fertilizer rolling friction coefficient | 0.05 | 0.25 | 0.45 |

| T7 | 有机肥-不锈钢碰撞恢复系数 Organic fertilizer-steel collided restitution coefficient | 0.15 | 0.40 | 0.65 |

| T8 | 有机肥-不锈钢静摩擦系数 Organic fertilizer-steel static friction coefficient | 0.10 | 0.50 | 0.90 |

| T9 | 有机肥-不锈钢滚动摩擦系数 Organic fertilizer-steelr rolling friction coefficient | 0.10 | 0.40 | 0.70 |

| T10 | JKR表面能JKR surface energy/(J·m-2) | 0.05 | 0.40 | 0.75 |

序号 No. | 参数水平 Parameter level | 堆积角 Repose angle/(°) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | T9 | T10 | ||

| 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 25.77 |

| 2 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | 14.07 |

| 3 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | 54.29 |

| 4 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 11.30 |

| 5 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | 21.69 |

| 6 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 22.29 |

| 7 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | 14.06 |

| 8 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | 52.31 |

| 9 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | 35.82 |

| 10 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | 67.48 |

| 11 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 50.51 |

| 12 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 50.94 |

| 13 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 74.62 |

| 14 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 50.06 |

| 15 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 23.89 |

| 16 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | 57.07 |

| 17 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 27.64 |

| 18 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | 59.01 |

| 19 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 56.59 |

| 20 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 31.52 |

| 21 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | 31.98 |

| 22 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | 32.03 |

| 23 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 51.46 |

| 24 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 11.94 |

| 25 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 41.89 |

表2 PB筛选试验结果

Table 2 Pile angle result of Plackett-Burman design

序号 No. | 参数水平 Parameter level | 堆积角 Repose angle/(°) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | T9 | T10 | ||

| 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 25.77 |

| 2 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | 14.07 |

| 3 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | 54.29 |

| 4 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | -1 | 11.30 |

| 5 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 1 | 21.69 |

| 6 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 22.29 |

| 7 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | -1 | 14.06 |

| 8 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | -1 | 52.31 |

| 9 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | -1 | 35.82 |

| 10 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 1 | 67.48 |

| 11 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 1 | 50.51 |

| 12 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 1 | 50.94 |

| 13 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 1 | 74.62 |

| 14 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 1 | 50.06 |

| 15 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | -1 | 23.89 |

| 16 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 1 | 57.07 |

| 17 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | -1 | 27.64 |

| 18 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 1 | 59.01 |

| 19 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 1 | 56.59 |

| 20 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | -1 | 31.52 |

| 21 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | -1 | 31.98 |

| 22 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 1 | 32.03 |

| 23 | -1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | -1 | 1 | 51.46 |

| 24 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 11.94 |

| 25 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 41.89 |

来源 Resources | 自由度 Df | 效应 Effect | 离均差平方和 Adi SS | 均方 Adi MS | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| 模型Model | 11 | 6 406.13 | 582.38 | 4.46 | 0.006** | |

| 线性Liner | 10 | 6 396.24 | 639.62 | 4.89 | 0.005** | |

| T1 | 1 | -1.80 | 19.37 | 19.37 | 0.15 | 0.707 |

| T2 | 1 | -0.96 | 5.51 | 5.51 | 0.04 | 0.841 |

| T3 | 1 | -5.62 | 189.73 | 189.73 | 1.45 | 0.250 |

| T4 | 1 | -0.20 | 0.25 | 0.25 | 0.00 | 0.966 |

| T5 | 1 | 4.55 | 124.03 | 124.03 | 0.95 | 0.348 |

| T6 | 1 | 4.35 | 113.36 | 113.36 | 0.87 | 0.369 |

| T7 | 1 | 10.87 | 709.16 | 709.16 | 5.43 | 0.037* |

| T8 | 1 | 11.87 | 845.38 | 845.38 | 6.47 | 0.025* |

| T9 | 1 | 2.52 | 38.10 | 38.10 | 0.29 | 0.598 |

| T10 | 1 | 26.93 | 4 351.35 | 4 351.35 | 33.29 | 0.000** |

| 弯曲Bend | 1 | 9.89 | 9.89 | 0.08 | 0.788 | |

| 误差Error | 13 | 1 699.32 | 130.72 | |||

| 合计Sum | 24 | 8 105.45 |

表3 PB筛选试验方差分析

Table 3 Analysis of variance of Plackett-Burman design

来源 Resources | 自由度 Df | 效应 Effect | 离均差平方和 Adi SS | 均方 Adi MS | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| 模型Model | 11 | 6 406.13 | 582.38 | 4.46 | 0.006** | |

| 线性Liner | 10 | 6 396.24 | 639.62 | 4.89 | 0.005** | |

| T1 | 1 | -1.80 | 19.37 | 19.37 | 0.15 | 0.707 |

| T2 | 1 | -0.96 | 5.51 | 5.51 | 0.04 | 0.841 |

| T3 | 1 | -5.62 | 189.73 | 189.73 | 1.45 | 0.250 |

| T4 | 1 | -0.20 | 0.25 | 0.25 | 0.00 | 0.966 |

| T5 | 1 | 4.55 | 124.03 | 124.03 | 0.95 | 0.348 |

| T6 | 1 | 4.35 | 113.36 | 113.36 | 0.87 | 0.369 |

| T7 | 1 | 10.87 | 709.16 | 709.16 | 5.43 | 0.037* |

| T8 | 1 | 11.87 | 845.38 | 845.38 | 6.47 | 0.025* |

| T9 | 1 | 2.52 | 38.10 | 38.10 | 0.29 | 0.598 |

| T10 | 1 | 26.93 | 4 351.35 | 4 351.35 | 33.29 | 0.000** |

| 弯曲Bend | 1 | 9.89 | 9.89 | 0.08 | 0.788 | |

| 误差Error | 13 | 1 699.32 | 130.72 | |||

| 合计Sum | 24 | 8 105.45 |

序号 No. | 有机肥-不锈钢碰撞恢复系数 Organic fertilizer-steel collided restitution coefficient | 有机肥-不锈钢静摩擦系数Organic fertilizer-steel static friction coefficient | JKR表面能 JKR surface energy/ (J·m-2) | 仿真结果 Simulation result/(°) | 含水率41.21%有机肥堆积角Repose angle of 41.21% moisture organic fertilizer | 含水率60.52%有机肥 堆积角Repose angle of 60.52% moisture organic fertilizer | |||

|---|---|---|---|---|---|---|---|---|---|

试验值 Test value/(°) | 相对误差 Relative error /% | 试验值 Test value/(°) | 相对误差 Relative error /% | ||||||

| 1 | 0.15 | 0.10 | 0.05 | 12.81 | 37.25 | 65.61 | 45.53 | 71.86 | |

| 2 | 0.25 | 0.25 | 0.20 | 26.22 | 29.61 | 42.41 | |||

| 3 | 0.35 | 0.40 | 0.35 | 44.36 | 16.03 | 2.57 | |||

| 4 | 0.45 | 0.55 | 0.50 | 67.23 | 44.59 | 32.28 | |||

| 5 | 0.55 | 0.70 | 0.65 | 71.44 | 47.86 | 36.27 | |||

表4 最陡爬坡试验结果

Table 4 Results of steep climbing test

序号 No. | 有机肥-不锈钢碰撞恢复系数 Organic fertilizer-steel collided restitution coefficient | 有机肥-不锈钢静摩擦系数Organic fertilizer-steel static friction coefficient | JKR表面能 JKR surface energy/ (J·m-2) | 仿真结果 Simulation result/(°) | 含水率41.21%有机肥堆积角Repose angle of 41.21% moisture organic fertilizer | 含水率60.52%有机肥 堆积角Repose angle of 60.52% moisture organic fertilizer | |||

|---|---|---|---|---|---|---|---|---|---|

试验值 Test value/(°) | 相对误差 Relative error /% | 试验值 Test value/(°) | 相对误差 Relative error /% | ||||||

| 1 | 0.15 | 0.10 | 0.05 | 12.81 | 37.25 | 65.61 | 45.53 | 71.86 | |

| 2 | 0.25 | 0.25 | 0.20 | 26.22 | 29.61 | 42.41 | |||

| 3 | 0.35 | 0.40 | 0.35 | 44.36 | 16.03 | 2.57 | |||

| 4 | 0.45 | 0.55 | 0.50 | 67.23 | 44.59 | 32.28 | |||

| 5 | 0.55 | 0.70 | 0.65 | 71.44 | 47.86 | 36.27 | |||

序号 NO. | T7:有机肥-不锈钢 碰撞恢复系数Organic fertilizer-steel collided restitution coefficient | T8:有机肥-不锈钢 静摩擦系数Organic fertilizer-steel static friction coefficient | T10:JKR 表面能 JKR surface energy/(J·m-2) | Y:堆积角 Repose angle/(°) |

|---|---|---|---|---|

| 1 | 0.25 | 0.25 | 0.35 | 32.89 |

| 2 | 0.45 | 0.25 | 0.35 | 37.94 |

| 3 | 0.25 | 0.55 | 0.35 | 42.28 |

| 4 | 0.45 | 0.55 | 0.35 | 45.99 |

| 5 | 0.25 | 0.40 | 0.20 | 43.51 |

| 6 | 0.45 | 0.40 | 0.20 | 42.59 |

| 7 | 0.25 | 0.40 | 0.50 | 38.97 |

| 8 | 0.45 | 0.40 | 0.50 | 41.47 |

| 9 | 0.35 | 0.25 | 0.20 | 29.68 |

| 10 | 0.35 | 0.55 | 0.20 | 40.71 |

| 11 | 0.35 | 0.25 | 0.50 | 33.35 |

| 12 | 0.35 | 0.55 | 0.50 | 43.64 |

| 13 | 0.35 | 0.40 | 0.35 | 39.92 |

| 14 | 0.35 | 0.40 | 0.35 | 38.61 |

| 15 | 0.35 | 0.40 | 0.35 | 42.51 |

表5 Box-Behnken Design方案及结果

Table 5 Scheme and results of Box-Behnken design

序号 NO. | T7:有机肥-不锈钢 碰撞恢复系数Organic fertilizer-steel collided restitution coefficient | T8:有机肥-不锈钢 静摩擦系数Organic fertilizer-steel static friction coefficient | T10:JKR 表面能 JKR surface energy/(J·m-2) | Y:堆积角 Repose angle/(°) |

|---|---|---|---|---|

| 1 | 0.25 | 0.25 | 0.35 | 32.89 |

| 2 | 0.45 | 0.25 | 0.35 | 37.94 |

| 3 | 0.25 | 0.55 | 0.35 | 42.28 |

| 4 | 0.45 | 0.55 | 0.35 | 45.99 |

| 5 | 0.25 | 0.40 | 0.20 | 43.51 |

| 6 | 0.45 | 0.40 | 0.20 | 42.59 |

| 7 | 0.25 | 0.40 | 0.50 | 38.97 |

| 8 | 0.45 | 0.40 | 0.50 | 41.47 |

| 9 | 0.35 | 0.25 | 0.20 | 29.68 |

| 10 | 0.35 | 0.55 | 0.20 | 40.71 |

| 11 | 0.35 | 0.25 | 0.50 | 33.35 |

| 12 | 0.35 | 0.55 | 0.50 | 43.64 |

| 13 | 0.35 | 0.40 | 0.35 | 39.92 |

| 14 | 0.35 | 0.40 | 0.35 | 38.61 |

| 15 | 0.35 | 0.40 | 0.35 | 42.51 |

来源 Resources | 自由度 Df | 均方 SSAdj | 离均差平方和 MSAdj | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 9 | 275.110 | 30.568 | 23.50 | 0.001** |

| T7 | 1 | 0.684 | 0.684 | 0.53 | 0.501 |

| T8 | 1 | 135.795 | 135.795 | 104.41 | 0.000** |

| T10 | 1 | 79.002 | 79.002 | 60.75 | 0.001** |

| T | 1 | 0.644 | 0.644 | 0.49 | 0.513 |

| T | 1 | 40.759 | 40.759 | 31.34 | 0.003** |

| T | 1 | 7.897 | 7.897 | 6.07 | 0.057 |

| T7T8 | 1 | 0.109 | 0.109 | 0.08 | 0.784 |

| T7T10 | 1 | 0.504 | 0.504 | 0.39 | 0.561 |

| T8T10 | 1 | 10.693 | 10.693 | 8.22 | 0.035* |

| 误差Error | 5 | 6.503 | 1.301 | ||

| 失拟项Lack of fit | 3 | 4.211 | 1.404 | 1.23 | 0.479 |

| 纯误差Pure error | 2 | 2.291 | 1.146 | ||

| 合计Sum | 14 | 281.613 |

表6 Box-Behnken Design二次回归模型方差分析

Table 6 ANOVA of Box-Behnken Design quadratic model

来源 Resources | 自由度 Df | 均方 SSAdj | 离均差平方和 MSAdj | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 9 | 275.110 | 30.568 | 23.50 | 0.001** |

| T7 | 1 | 0.684 | 0.684 | 0.53 | 0.501 |

| T8 | 1 | 135.795 | 135.795 | 104.41 | 0.000** |

| T10 | 1 | 79.002 | 79.002 | 60.75 | 0.001** |

| T | 1 | 0.644 | 0.644 | 0.49 | 0.513 |

| T | 1 | 40.759 | 40.759 | 31.34 | 0.003** |

| T | 1 | 7.897 | 7.897 | 6.07 | 0.057 |

| T7T8 | 1 | 0.109 | 0.109 | 0.08 | 0.784 |

| T7T10 | 1 | 0.504 | 0.504 | 0.39 | 0.561 |

| T8T10 | 1 | 10.693 | 10.693 | 8.22 | 0.035* |

| 误差Error | 5 | 6.503 | 1.301 | ||

| 失拟项Lack of fit | 3 | 4.211 | 1.404 | 1.23 | 0.479 |

| 纯误差Pure error | 2 | 2.291 | 1.146 | ||

| 合计Sum | 14 | 281.613 |

组别 Group | 含水率 Moisture content/% | 堆积角试验值 Repose angle test value/(°) | 堆积角仿真值 Repose angle simulation value/(°) | 相对误差 Relative error/% | 有机肥-不锈钢碰撞恢复系数 Organic fertilizer-steel collided restitution coefficient | 有机肥-不锈钢静摩擦系数Organic fertilizer-steel static friction coefficient | JKR表面能 JKR surface energy/(J·m-2) |

|---|---|---|---|---|---|---|---|

| A1 | 41.21 | 37.25 | 37.84 | 1.56 | 0.43 | 0.34 | 0.22 |

| A2 | 44.46 | 38.67 | 39.53 | 2.18 | 0.29 | 0.35 | 0.24 |

| A3 | 51.37 | 41.62 | 42.73 | 2.60 | 0.35 | 0.36 | 0.32 |

| A4 | 56.56 | 42.83 | 41.52 | 3.06 | 0.26 | 0.39 | 0.32 |

| A5 | 60.52 | 45.53 | 46.81 | 2.73 | 0.43 | 0.38 | 0.47 |

表7 模型验证试验结果

Table 7 Model verification test results

组别 Group | 含水率 Moisture content/% | 堆积角试验值 Repose angle test value/(°) | 堆积角仿真值 Repose angle simulation value/(°) | 相对误差 Relative error/% | 有机肥-不锈钢碰撞恢复系数 Organic fertilizer-steel collided restitution coefficient | 有机肥-不锈钢静摩擦系数Organic fertilizer-steel static friction coefficient | JKR表面能 JKR surface energy/(J·m-2) |

|---|---|---|---|---|---|---|---|

| A1 | 41.21 | 37.25 | 37.84 | 1.56 | 0.43 | 0.34 | 0.22 |

| A2 | 44.46 | 38.67 | 39.53 | 2.18 | 0.29 | 0.35 | 0.24 |

| A3 | 51.37 | 41.62 | 42.73 | 2.60 | 0.35 | 0.36 | 0.32 |

| A4 | 56.56 | 42.83 | 41.52 | 3.06 | 0.26 | 0.39 | 0.32 |

| A5 | 60.52 | 45.53 | 46.81 | 2.73 | 0.43 | 0.38 | 0.47 |

| 1 | 陈秋红,张宽.新中国70年畜禽养殖废弃物资源化利用演进[J].中国人口·资源与环境,2020,30(6):166-176. |

| CHEN Q H, ZHANG K. The evolution of resource utilization of livestock and poultry breeding waste in the past 70 years since the founding of P.R. China [J]. China Population,Resour. Environ., 2020, 30(6):166-176. | |

| 2 | BESKINA K V, HOLCOMBA C D, CAMMACKA J A, et al.. Larval digestion of different manure types by the black soldier fly(Diptera:Stratiomyidae) impacts associated volatile emissions [J]. Waste Manage., 2018, 74: 213-220. |

| 3 | 杨晓杰,游秀峰,李为争,等.虫粪的生态学功能[J].华中昆虫研究, 2019(15): 64-74. |

| YANG X J, YOU X F, LI W Z, et al.. Ecological significance of insect frass [J]. Insects Res. Central China, 2019(15): 64-74. | |

| 4 | 徐齐云,龙镜池,叶明强,等.黑水虻幼虫的发育速率及食物转化率研究[J].环境昆虫学报,2014,36(4):561-564. |

| XU Q Y, LONG J C, YE M Q, et al.. Development rate and food conversion efficiency of black soldier fly,Hermetia illucens [J]. J. Environ. Entomol., 2014,36 (4): 561-564. | |

| 5 | 袁橙,魏冬霞,解慧梅,等.黑水虻幼虫处理规模化猪场粪污的试验研究[J].畜牧与兽医,2019,51 (11): 49-53. |

| YUAN C, WEI D X, XIE H M, et al.. Research on treatment of fecal pollution on large scale pig farms with black soldier fly larva [J]. Anim. Husbandry Vet-erinary Med., 2019,51(11): 49-53. | |

| 6 | 王小波,蔡瑞婕,耿维娜,等.黑水虻生物转化猪粪过程中重金属的迁移变化[J].农业工程学报,2020,36(20):263-268. |

| WANG X B, CAI R J, GENG W N, et al.. Migration and changes of heavy metals during biotransformation of pig manure by black soldier fly [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(20):263-268. | |

| 7 | 张金金,王瑞华,张邦,等.黑水虻幼虫粉对蛋鸡产蛋后期生产性能、蛋品质及血液生理生化指标的影响[J].动物营养学报,2020,32(4):1658-1665. |

| ZHANG J J, WANG R H, ZHANG B, et al.. Effects of black soldier fly larvae meal on performance, egg quality and blood physiological and biochemical parameters of hens during late laying period [J]. Chin. J. Anim. Nutr., 2020, 32(4):1658-1665. | |

| 8 | 彭才望,许道军,贺喜,等.黑水虻处理的猪粪有机肥离散元仿真模型参数标定[J].农业工程学报,2020,36(17):212-218. |

| PENG C W, XU D J, HE X, et al.. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(17): 212-218. | |

| 9 | 彭才望,贺喜,孙松林,等.斗式黑水虻处理猪粪有机肥取料机设计与试验[J].农业机械学报,2021,52(2):145-156. |

| PENG C W, HE X, SUN S L, et al.. Design and experiment on shoveling device of pig manure organic fertilizer by Hermetia illucen transforming based on bucket-wheel mechanism [J]. Trans. Chin. Soc. Agric. Mach., 2021,52(2):145-156. | |

| 10 | 彭才望,孙松林,贺喜,等.双向螺旋黑水虻虫沙收集装置设计与试验[J].浙江大学学报(农业与生命科学版),2020,46(5):637-646. |

| PENG C W, SUN S L, HE X, et al.. Design and experiment of bidirectional spiral collecting device for Hermetia illucens insect sand [J]. J. Zhejiang Univ. (Agric. Life Sci.), 2020,46(5):637-646. | |

| 11 | 谢洪勇,刘志军.粉体力学与工程[M].北京:化学工业出版社,2007:31-32. |

| 12 | 李俊伟,佟金,胡斌,等.不同含水率黏重黑土与触土部件互作的离散元仿真参数标定[J]. 农业工程学报,2019,35(6):130-140. |

| LI J W, TONG J, HU B, et al.. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(6): 130-140. | |

| 13 | 林嘉聪,罗帅,袁巧霞,等.不同含水率蚯蚓粪颗粒物料流动性研究[J]. 农业工程学报,2019,35(9):221-227. |

| LIN J C, LUO S, YUAN Q X, et al.. Flow properties of vermicompost particle with different moisture contents [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(9):221-227. | |

| 14 | 罗帅,袁巧霞, GOUDA Shaban,等.基于JKR粘结模型的蚯蚓粪基质离散元法参数标定[J].农业机械学报,2018,49(4):343-350. |

| LUO S, YUAN Q X, SHABAN G, et al.. Parameters calibration of vermicomposting nursery substrate with discrete element method based on JKR contact model [J]. Trans. Chin. Soc. Agric. Mach., 2018,49(4):343-350. | |

| 15 | 王黎明,范盛远,程红胜,等.基于 EDEM 的猪粪接触参数标定[J].农业工程学报,2020,36(15):95-102. |

| WANG L M, FAN S Y, CHENG H S, et al.. Calibration of contact parameters for pig manure based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(15): 95-102. | |

| 16 | 袁全春,徐丽明,邢洁洁,等. 机施有机肥散体颗粒离散元模型参数标定[J].农业工程学报,2018,34(18):21-27. |

| YUAN Q C, XU L M, XING J J, et al.. Parameter calibration of discrete element model of organic fertilizer particles for mechanical fertilization [J]. Trans. Chin. Soc. Agric. Eng., 2018,34(18):21-27. | |

| 17 | 王宪良,胡红,王庆杰,等. 基于离散元的土壤模型参数标定方法[J].农业机械学报,2017,48(12):78-85. |

| WANG X L, HU H, WANG Q J, et al.. Calibration method of soil contact characteristic parameters based on DEM theory [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(12):78-85. | |

| 18 | 石林榕,赵武云,孙伟. 基于离散元的西北旱区农田土壤颗粒接触模型和参数标定[J]. 农业工程学报,2017,33(21):181-187. |

| SHI L R, ZHAO W Y, SUN W. Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(21): 181-187. | |

| 19 | 田晓红,李光涛,张淑丽. 谷物自然休止角测量方法的探究[J]. 粮食加工,2010,35(1):68-71. |

| TIAN X H, LI G T, ZHANG S L. Determination of angle of repose [J]. Grain Process., 2010, 35(1): 68-71. | |

| 20 | UCGUL M, FIELKE J M, SAUNDERS C. Three-dimensional discrete element modelling (DEM) of tillage: accounting for soil cohesion and adhesion [J]. Biosyst. Eng., 2015, 129(1): 298-306. |

| 21 | PEELE K A, RUPANIDHI S, REDDY E R, et al.. Plackett-Burman design for screening of process components and their effects on production of lactase by newly isolated Bacillus sp. VUVD101 strain from dairy effluent [J].Beni-Suef Univ. J. Basic Appl. Sci., 2018, 7(4): 543-546. |

| 22 | JOHNSON K L, KENDALL K, ROBERTS A D. Surface energy and the contact of elastic solids [J]. Proc. R. Soc. Lond. A, 1971,324(1558): 301-313. |

| 23 | KALKAN F, KARA M. Handling, frictional and technological properties of wheat as affected by moisture content and cultivar [J]. Powder Technol., 2011, 213(1/3): 116-122. |

| [1] | 张海东, 唐志贤, 张立芸, 于淇, 宋朝君. 基于GA-BP-GA优化林下三七种植红壤离散元仿真参数[J]. 中国农业科技导报, 2025, 27(9): 120-130. |

| [2] | 寇威, 刘佳月, 户可欣, 高铱遥, 许世奇, 何彦臻, 王旭东. 有机肥与鼠李糖脂和氯化胆碱配施对盐渍土性质和番茄耐盐性的影响[J]. 中国农业科技导报, 2025, 27(8): 202-214. |

| [3] | 奚小波, 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏. 一种果园中耕避障除草机的设计与试验[J]. 中国农业科技导报, 2025, 27(7): 101-110. |

| [4] | 周琦, 刘强, 张靖, 邓超超, 王振龙, 柳洋, 吴芳, 常浩, 周彦芳, 宿翠翠, 施志国, 高正睿, 马凤捷. 有机肥替代化肥对土壤生物学特性及南瓜产量的影响[J]. 中国农业科技导报, 2025, 27(7): 190-203. |

| [5] | 张曦瑜, 沈幸, 李伟, 谢文歌, 李杰, 杨昌浩, 柴仲平. 氮肥减量配施有机肥对库尔勒香梨园土壤细菌群落结构的影响[J]. 中国农业科技导报, 2025, 27(7): 217-228. |

| [6] | 许静, 李晗, 陈平录, 罗江旎, 唐承露, 刘木华. 油茶茶枯离散元模型参数标定与试验[J]. 中国农业科技导报, 2025, 27(3): 112-121. |

| [7] | 李大荣, 李小玲, 周武先, 张美德, 蒋小刚, 由金文, 王华. 有机肥替代部分化肥对湖北贝母生长及土壤性质的影响[J]. 中国农业科技导报, 2025, 27(3): 216-226. |

| [8] | 冯长龙, 黄春光, 宁辰阳, 李树平, 陈科锦. 植树机挖坑机构螺旋式钻头性能特性优化研究[J]. 中国农业科技导报, 2025, 27(2): 89-98. |

| [9] | 田祥州, 贺福强, 陈发江, 詹璐歆. 基于休止角标定不同含水率木粉离散元参数[J]. 中国农业科技导报, 2025, 27(1): 118-128. |

| [10] | 郗婧怡, 王双庆, 白一彤, 姚秀利, 黄碧璇, 李青怡, 范丽清, 黄世臣, 孙明国. 响应面法优化黑水虻处理餐厨垃圾工艺参数研究[J]. 中国农业科技导报, 2025, 27(1): 241-249. |

| [11] | 顿国强, 王雷, 纪欣鑫, 姜新波, 赵宇, 郭娜. 金乡紫皮蒜种离散元参数标定与试验验证[J]. 中国农业科技导报, 2024, 26(8): 131-139. |

| [12] | 王兴松, 王娜, 杜宇, 周鹏, 王戈, 贾孟, 徐照丽, 白羽祥. 有机肥对玉溪植烟土壤有机质组分和微生物群落结构的影响[J]. 中国农业科技导报, 2024, 26(8): 201-212. |

| [13] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [14] | 韩秀丽, 李嘉伟, 张杰, 郭艳杰, 张丽娟, 吉艳芝. 生物有机肥替代化肥对葡萄生长与土壤肥力的影响[J]. 中国农业科技导报, 2024, 26(4): 195-205. |

| [15] | 李明, 董帅, 庞永强, 燕洁华, 叶汪忠. 风沙土混拌刀具的改良设计与试验[J]. 中国农业科技导报, 2024, 26(4): 87-96. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||