Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (3): 130-139.DOI: 10.13304/j.nykjdb.2021.0673

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Qin FANG( ), Shisheng SONG, Ting ZHOU, Caiwang PENG(

), Shisheng SONG, Ting ZHOU, Caiwang PENG( ), Songlin SUN(

), Songlin SUN( ), Haiying ZHU

), Haiying ZHU

Received:2021-08-09

Accepted:2021-11-22

Online:2022-03-15

Published:2022-03-14

Contact:

Caiwang PENG,Songlin SUN

方芹( ), 宋世圣, 周婷, 彭才望(

), 宋世圣, 周婷, 彭才望( ), 孙松林(

), 孙松林( ), 朱海英

), 朱海英

通讯作者:

彭才望,孙松林

作者简介:方芹 E-mail:2512353158@qq.com

基金资助:CLC Number:

Qin FANG, Shisheng SONG, Ting ZHOU, Caiwang PENG, Songlin SUN, Haiying ZHU. Design and Experiment of a Two-Stage Segmented Drum Screening Device for Black Soldier Fly Insect Sand[J]. Journal of Agricultural Science and Technology, 2022, 24(3): 130-139.

方芹, 宋世圣, 周婷, 彭才望, 孙松林, 朱海英. 两级分段式黑水虻虫沙滚筒筛分装置设计与试验[J]. 中国农业科技导报, 2022, 24(3): 130-139.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2021.0673

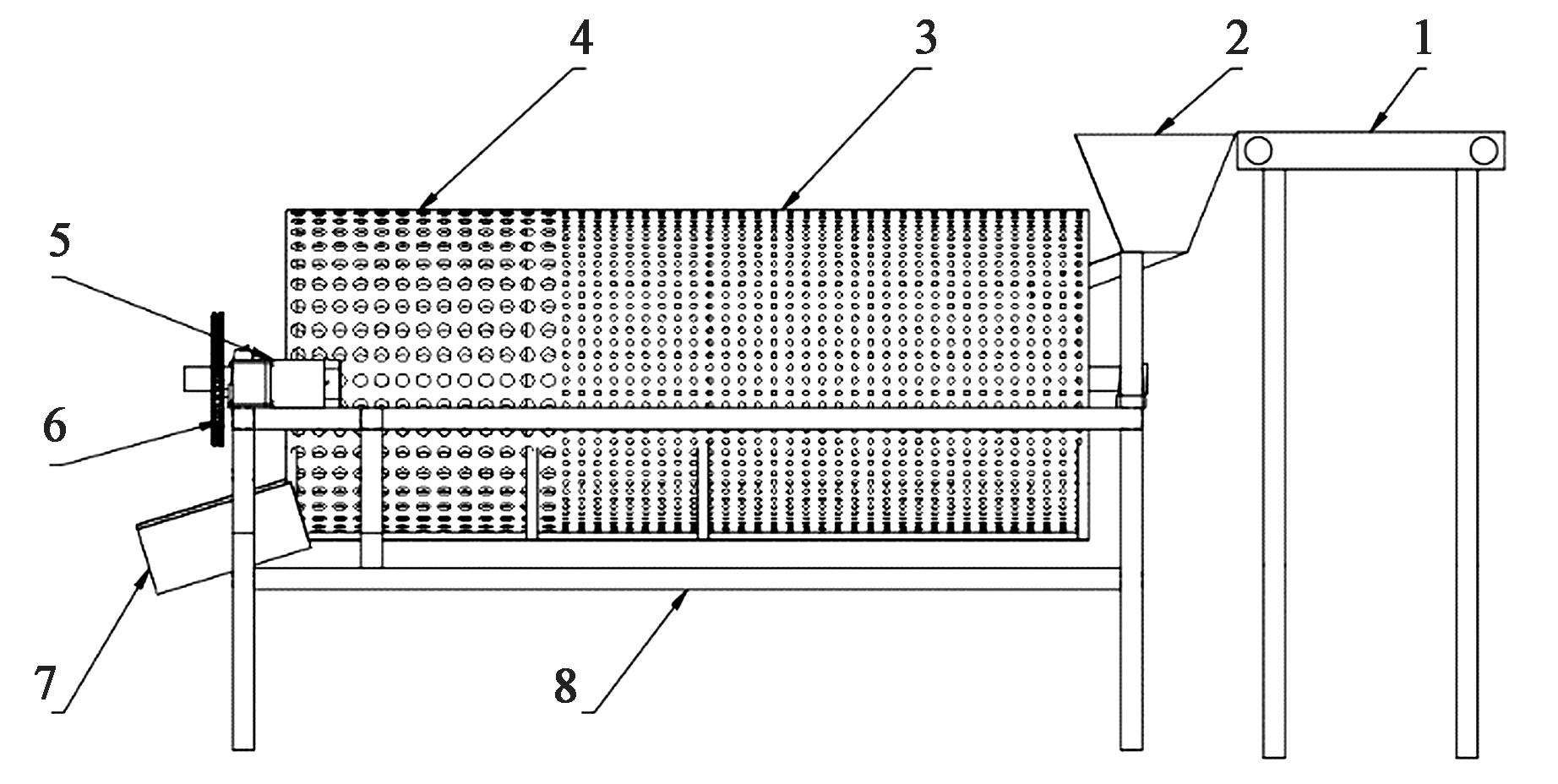

Fig.1 Structure of two?stage segmented black soldier fly insect sand separation drum screenNote: 1—Conveyor belt; 2—Feeding port; 3—First level screen; 4—Secondary screen; 5—Speed regulating motor; 6—Transmission system; 7—Discharge port; 8—Frame.

水平 Level | 因素Factor | ||

|---|---|---|---|

A:滚筒转速 Drum speed/(r·min-1) | B:滚筒倾角 Drum inclination angle/(°) | C:喂入量 Feeding amount/(t·h-1) | |

| -1 | 30 | 5 | 1.2 |

| 0 | 40 | 6 | 1.5 |

| 1 | 50 | 7 | 1.8 |

Table 1 Coding of test factors

水平 Level | 因素Factor | ||

|---|---|---|---|

A:滚筒转速 Drum speed/(r·min-1) | B:滚筒倾角 Drum inclination angle/(°) | C:喂入量 Feeding amount/(t·h-1) | |

| -1 | 30 | 5 | 1.2 |

| 0 | 40 | 6 | 1.5 |

| 1 | 50 | 7 | 1.8 |

序号 Number | A:滚筒转速 Drum speed/(r·min-1) | B:滚筒倾角 Drum inclination angle/(°) | C:喂入量 Feeding amount/(t·h-1) | Y1:含杂率 Impurity rate/% | Y2:损失率 Loss rate/% |

|---|---|---|---|---|---|

| 1 | 30 | 5 | 1.5 | 1.50 | 12.16 |

| 2 | 50 | 5 | 1.5 | 2.00 | 19.05 |

| 3 | 30 | 7 | 1.5 | 1.10 | 9.46 |

| 4 | 50 | 7 | 1.5 | 1.25 | 18.37 |

| 5 | 30 | 6 | 1.2 | 1.65 | 9.92 |

| 6 | 50 | 6 | 1.2 | 1.95 | 18.33 |

| 7 | 30 | 6 | 1.8 | 1.21 | 8.43 |

| 8 | 50 | 6 | 1.8 | 1.80 | 16.85 |

| 9 | 40 | 5 | 1.2 | 1.11 | 15.38 |

| 10 | 40 | 7 | 1.2 | 0.95 | 14.75 |

| 11 | 40 | 5 | 1.8 | 1.30 | 13.83 |

| 12 | 40 | 7 | 1.8 | 2.40 | 9.60 |

| 13 | 40 | 6 | 1.5 | 1.40 | 13.42 |

| 14 | 40 | 6 | 1.5 | 1.50 | 12.75 |

| 15 | 40 | 6 | 1.5 | 1.38 | 13.33 |

| 16 | 40 | 6 | 1.5 | 1.49 | 12.84 |

| 17 | 40 | 6 | 1.5 | 1.53 | 12.34 |

Table 2 Experiment design and response values

序号 Number | A:滚筒转速 Drum speed/(r·min-1) | B:滚筒倾角 Drum inclination angle/(°) | C:喂入量 Feeding amount/(t·h-1) | Y1:含杂率 Impurity rate/% | Y2:损失率 Loss rate/% |

|---|---|---|---|---|---|

| 1 | 30 | 5 | 1.5 | 1.50 | 12.16 |

| 2 | 50 | 5 | 1.5 | 2.00 | 19.05 |

| 3 | 30 | 7 | 1.5 | 1.10 | 9.46 |

| 4 | 50 | 7 | 1.5 | 1.25 | 18.37 |

| 5 | 30 | 6 | 1.2 | 1.65 | 9.92 |

| 6 | 50 | 6 | 1.2 | 1.95 | 18.33 |

| 7 | 30 | 6 | 1.8 | 1.21 | 8.43 |

| 8 | 50 | 6 | 1.8 | 1.80 | 16.85 |

| 9 | 40 | 5 | 1.2 | 1.11 | 15.38 |

| 10 | 40 | 7 | 1.2 | 0.95 | 14.75 |

| 11 | 40 | 5 | 1.8 | 1.30 | 13.83 |

| 12 | 40 | 7 | 1.8 | 2.40 | 9.60 |

| 13 | 40 | 6 | 1.5 | 1.40 | 13.42 |

| 14 | 40 | 6 | 1.5 | 1.50 | 12.75 |

| 15 | 40 | 6 | 1.5 | 1.38 | 13.33 |

| 16 | 40 | 6 | 1.5 | 1.49 | 12.84 |

| 17 | 40 | 6 | 1.5 | 1.53 | 12.34 |

变异来源 Source | 含杂率Impurity rate | |||

|---|---|---|---|---|

自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型Molel | 11 | 0.20 | 40.22 | 0.000 4** |

| A | 1 | 0.30 | 60.25 | 0.000 6** |

| B | 1 | 0.22 | 44.90 | 0.001 1** |

| C | 1 | 0.67 | 136.67 | <0.000 1** |

| AB | 1 | 0.031 | 6.22 | 0.054 8 |

| AC | 1 | 0.021 | 4.27 | 0.093 6 |

| BC | 1 | 0.40 | 80.67 | 0.000 3** |

| A2 | 1 | 0.049 | 9.89 | 0.025 5* |

| B2 | 1 | 0.046 | 9.44 | 0.027 7* |

| C2 | 1 | 0.030 | 6.18 | 0.055 4 |

| 残差Residual | 5 | |||

| 失拟项Lack of fit | 1 | 1.66 | 0.267 7 | |

| 纯误差Pure error | 4 | |||

Table 3 Significance test result of impurity rate model

变异来源 Source | 含杂率Impurity rate | |||

|---|---|---|---|---|

自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型Molel | 11 | 0.20 | 40.22 | 0.000 4** |

| A | 1 | 0.30 | 60.25 | 0.000 6** |

| B | 1 | 0.22 | 44.90 | 0.001 1** |

| C | 1 | 0.67 | 136.67 | <0.000 1** |

| AB | 1 | 0.031 | 6.22 | 0.054 8 |

| AC | 1 | 0.021 | 4.27 | 0.093 6 |

| BC | 1 | 0.40 | 80.67 | 0.000 3** |

| A2 | 1 | 0.049 | 9.89 | 0.025 5* |

| B2 | 1 | 0.046 | 9.44 | 0.027 7* |

| C2 | 1 | 0.030 | 6.18 | 0.055 4 |

| 残差Residual | 5 | |||

| 失拟项Lack of fit | 1 | 1.66 | 0.267 7 | |

| 纯误差Pure error | 4 | |||

变异来源 Source | 损失率Loss rate | |||

|---|---|---|---|---|

自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型Model | 9 | 18.39 | 43.86 | <0.000 1** |

| A | 1 | 133.09 | 317.52 | <0.000 1** |

| B | 1 | 8.49 | 20.25 | 0.002 8** |

| C | 1 | 11.69 | 27.89 | 0.001 1** |

| AB | 1 | 1.02 | 2.43 | 0.162 7 |

| AC | 1 | 0.994 1 | ||

| BC | 1 | 3.24 | 7.73 | 0.027 3* |

| A2 | 1 | 3.47 | 8.29 | 0.023 7* |

| B2 | 1 | 3.53 | 8.42 | 0.022 9* |

| C2 | 1 | 0.90 | 2.14 | 0.186 7 |

| 残差Residual | 7 | 0.42 | ||

| 失拟项Lack of fit | 3 | 0.72 | 3.63 | 0.122 6 |

| 纯误差Pure error | 4 | 0.20 | ||

Table 4 Significance test result of loss rate model

变异来源 Source | 损失率Loss rate | |||

|---|---|---|---|---|

自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型Model | 9 | 18.39 | 43.86 | <0.000 1** |

| A | 1 | 133.09 | 317.52 | <0.000 1** |

| B | 1 | 8.49 | 20.25 | 0.002 8** |

| C | 1 | 11.69 | 27.89 | 0.001 1** |

| AB | 1 | 1.02 | 2.43 | 0.162 7 |

| AC | 1 | 0.994 1 | ||

| BC | 1 | 3.24 | 7.73 | 0.027 3* |

| A2 | 1 | 3.47 | 8.29 | 0.023 7* |

| B2 | 1 | 3.53 | 8.42 | 0.022 9* |

| C2 | 1 | 0.90 | 2.14 | 0.186 7 |

| 残差Residual | 7 | 0.42 | ||

| 失拟项Lack of fit | 3 | 0.72 | 3.63 | 0.122 6 |

| 纯误差Pure error | 4 | 0.20 | ||

指标 Index | 含杂率 Impurity rate/% | 损失率 Loss rate/% |

|---|---|---|

平均实际值 Average actual value | 1.165 | 8.877 |

预测值 Predictive value | 1.109 | 8.430 |

相对误差 Relative error | 4.807 | 5.035 |

Tab.5 Verification result

指标 Index | 含杂率 Impurity rate/% | 损失率 Loss rate/% |

|---|---|---|

平均实际值 Average actual value | 1.165 | 8.877 |

预测值 Predictive value | 1.109 | 8.430 |

相对误差 Relative error | 4.807 | 5.035 |

| 1 | 王攀,任连海,甘筱.城市餐厨垃圾产生现状调查及影响因素分析[J].环境科学与技术, 2013, 36 (3): 181-185. |

| WANG P, REN L H, GAN X. Investigation and output factors analysis garbage for cities in China [J]. Environ. Sci. Technol., 2013, 36 (3): 181-185. | |

| 2 | LI P Y, XIE Y, ZENG Y, et al.. Bioconversion of welan gum from kitchen waste by a two-step enzymatic hydrolysis pretreatment [J]. Appl. Biochem. Biotechnol., 2017, 183 (3): 820-832. |

| 3 | 梅冰,窦法楷,汪慧莲,等.餐厨垃圾处理技术研究进展[J].环境卫生工程, 2015,23 (5): 17-18. |

| MEI B, DOU F K, WANG H L, et al.. Research progress of food waste treatment technology [J]. Environ. Sanitation Eng., 2015, 23 (5): 17-18. | |

| 4 | NGUYEN T T X, TOMBERLIN J K, VANLAERHOVEN S. Ability of black soldier fly (Diptera:Stratiomyidae) larvae to recycle food waste [J]. Environ. Entomol., 2015, 44 (2): 406-410. |

| 5 | 张杰,温逸婷,高正辉,等.黑水虻的资源化利用研究现状[J].应用昆虫学报, 2019, 56 (5): 997-1006. |

| ZHANG J, WEN Y T, GAO Z H, et al.. Progress in research on and the utilization of Hermetia illucens [J]. Acta Appl. Entomol., 2019, 56 (5): 997-1006. | |

| 6 | 尹靖凯,龚小燕,孙丽娜,等.黑水虻对餐厨垃圾养分转化研究[J].中国农业科技导报, 2021, 23 (6): 154-159. |

| YIN J K, GONG X Y, SUN L, et al.. Study on the transformation of nutrients kitchen waste by black soldier fly [J]. J. Agric. Sci. Technol., 2021, 23 (6): 154-159. | |

| 7 | 柴志强,朱彦光.黑水虻在餐厨垃圾处理中的应用[J].科技展望, 2016, 26 (22): 321. |

| 8 | 张钰. 煤泥脱水筛分滚筒筛性能试验研究与离散元模拟[D].太原: 太原理工大学, 2016. |

| ZHANG Y. Experimental study and discrete element simulation of coal slime dewatering sieving drum screen’s performance [D]. Taiyuan: Taiyuan University of Technology, 2016. | |

| 9 | 张林海,薛党勤,马世榜,等.农作物秸秆物料杂质及滚筒筛分研究[J].太阳能学报, 2014, 35 (3): 433-438. |

| ZHANG L H, XUE D Q, MA S B, et al.. Research on impurities of the cropstraw and trommel sieve [J]. Acta Solar Energy, 2014, 35 (3): 433-438. | |

| 10 | 石鑫,牛长河,王学农,等.滚筒筛式废旧地膜与杂质风选装置设计[J].农业工程学报, 2017, 33 (18): 19-26. |

| SHI X, NIU C H, WANG X N, et al.. Design of rolller sieve plastic film and trash winnowing machine [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33 (18): 19-26. | |

| 11 | 李心平,孟亚娟,张家亮,等.辊搓圆筒筛式谷子清选装置设计与试验[J].农业机械学报, 2018, 49 (10): 92-102, 136. |

| LI X P, MENG Y J, ZHANG J L, et al.. Design and experiment of longitudinal axial flow double flexible rolling and kneading threshing device for millet [J]. Trans. Chin. Soc. Agric. Machinery, 2018, 49 (10): 92-102, 136. | |

| 12 | 彭强吉,李成松,康建明,等.气力式圆筒筛膜杂分离机改进设计与试验[J].农业机械学报, 2020, 51 (8): 126-135. |

| PENG Q J, Li C S, KANG J M, et al.. Improved design and test of pneumatic cylindrical sieve film hybrid separator [J]. Trans. Chin. Soc. Agric. Machinery, 2020, 51 (8): 126-135. | |

| 13 | 王升升,陈盼,卢梦晴,等.大白菜种子收获分离清选装置设计与试验[J].农业机械学报, 2020, 51 (S2): 181-190. |

| WANG S S, CHEN P, LU M Q, et al.. Design and experiment of separation and cleaning device for Chinese cabbage seeds harvester [J]. Trans. Chin. Soc. Agric. Machinery, 2020, 51 (S2): 181-190. | |

| 14 | 姬越,安新城,徐齐云.一种风干式黑水虻幼虫分离装置:CN206491189U [P]. 2017-09-15. |

| 15 | 徐美庆,周建新.一种利用黑水虻幼虫处理餐厨垃圾用虫粪分离装置: CN207978745U [P]. 2020-07-23. |

| 16 | 曹卫彬,焦灏博,刘姣娣,等.基于TRIZ理论的红花丝盲采装置设计与试验[J].农业机械学报, 2018, 49 (8): 76-82. |

| CAO W B, JIAO H B, LIU J D, et al.. Design and safflower filament picking device based on TRIZ theory [J]. Trans. Chin. Soc. Agric. Machinery, 2018, 49 (8): 76-82. | |

| 17 | 李兵.生活垃圾深度分选及设备优化组合技术研究[D].上海: 同济大学, 2006. |

| LI B. Integrated mechanical separation and parameter optimization for municipal solid wastes [D]. Shanghai: Tongji University, 2006. | |

| 18 | 中国农业机械化科学研究院.农业机械设计手册 (下册) [M].北京:中国农业科学技术出版社, 2007: 965-966. |

| 19 | 康建明,张恒,张国海,等.残膜物料空气动力学特性与膜杂分离装置试验[J].中国农机化学报, 2020, 41 (1): 167-172. |

| KANG J M, ZHANG H, ZHANG G H, et al.. Aerodynamic characteristics of residual film materials and test of membrane separation device [J]. J. Chin. Agric. Mechanization, 2020, 41 (1): 167-172. | |

| 20 | 刘廷发.堆肥滚筒筛分机开发研究[D].北京:中国农业机械化科学研究院, 2017. |

| LIU T F. Research and design of compost trommel screen [D]. Beijing: Chinese Academy of Agricultural Mechanization Sciences, 2017. | |

| 21 | 李兵,董志颖,赵由才,等.城市生活垃圾滚筒筛分选特性研究[J].环境科学学报, 2011, 31 (10): 2268-2274. |

| LI B, DONG Z Y, ZHAO Y C, et al.. Study on the mechanical separation characteristics for municipal solid waste using trommel screener [J]. Acta Sci. Circum., 2011, 31 (10): 2268-2274. | |

| 22 | 康建明,陈学庚,温浩军,等.基于响应面法的梳齿式采棉机采收台优化设计[J/OL].农业机械学报, 2013, 44 (S2): 57-61. |

| KANG J M, CHEN X G, WEN H J, et al.. Optimization of comb-type cotton picker device based on response surface methodology [J/OL]. Trans. Chin. Soc. Agric. Machinery, 2013, 44 (S2): 57-61. | |

| 23 | 任露泉.试验优化设计与分析[M].第2版.北京:高等教育出版社, 2003:1-585. |

| [1] | Haidong ZHANG, Zhixian TANG, Liyun ZHANG, Qi YU, Chaojun SONG. Optimization of Discrete Elemental Simulation Parameters for Forest Panax pseudoginseng Plantation Red Soil Based on GA-BP-GA [J]. Journal of Agricultural Science and Technology, 2025, 27(9): 120-130. |

| [2] | Shuoshuo FU, Weiyong GONG, Yixuan LIN, Yuanshun LI, Chengcan LIU, Lin NI. Optimization of Extraction Technology and Antifungal Activity of Total Diterpene from Fokienia Hodginsii [J]. Journal of Agricultural Science and Technology, 2025, 27(5): 146-155. |

| [3] | Chunlin MIAO, Huanhuan XU, Ziyi JIA, Aimin HE, Yangyang JI, Dehua MOU, Shan GAO. Oxidation Resistance Analysis and Component Identification of Distracted Wood Water Extracts [J]. Journal of Agricultural Science and Technology, 2025, 27(5): 182-192. |

| [4] | Changlong FENG, Chenyang NING, Yixin ZHU, Shuping LI, Chunguang HUANG. Research on Design and Optimization of Ring Winding Mechanism for Trunk Bandages [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 122-132. |

| [5] | Ruyan ZHANG, Shenhao LI, Qipeng ZHU, Taigang FENG, Hongbo LI, Zebing XING, Yu XIAN. Effect of Biochar Content on Physical and Mechanical Properties of Garden Greening Waste/polylactic Acid Composites [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 192-200. |

| [6] | Changlong FENG, Chunguang HUANG, Chenyang NING, Shuping LI, Kejin CHEN. Optimization of Performance and Characteristics of Spiral Drill Bit Excavation Mechanism for Planting Machine [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 89-98. |

| [7] | Xue WANG, Xing ZHENG, Jiamiao REN, Yazhou ZHAO, Wenjun PENG. Optimization of Extraction Conditions for Volatile Components in Jujube Honey Based on Plackett-Burman Design and Response Surface Method [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 181-192. |

| [8] | Jingyi XI, Shuangqing WANG, Yitong BAI, Xiuli YAO, Bixuan HUANG, Qingyi LI, Liqing FAN, Shichen HUANG, Mingguo SUN. Study on Optimization of Processing Parameters Using Hermetia illucens Larva to Treat Food Waste by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 241-249. |

| [9] | Lijun FU, Xiaoyu LIN, Jianhua LIN, Huinan SHEN, Yongzhen WU. Research on Processing Technology and Shelf Life of Red Matsutake Beef Sauce [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 148-158. |

| [10] | Lanxiong ZHANG, Wei ZHENG, Yuan’an CHEN, Jing SHEN, Shuangquan ZOU, Jianrong WU, Lin NI. Study on Extraction Process and Antibacterial Activity of Lignans from Cinnamomum camphora Leaves [J]. Journal of Agricultural Science and Technology, 2024, 26(5): 138-147. |

| [11] | Dongling LIU, Hao SI, Baojiang ZHENG, Yuhong ZHANG. Optimization of Enzyme Assisted-ultrasonic Extraction of Sinigrin in Thlaspi arvense Seeds by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 225-233. |

| [12] | Lei JI, Hongyan LI, Ying WANG, Xiaodong JIANG, Tianhong LIU, Xiao LI, Yuanqin SUN, Hongjun LIU. Optimization of Processing Technology and Analysis of Aroma Components of Tomato Flavored Puffed Shrimp Slices [J]. Journal of Agricultural Science and Technology, 2024, 26(1): 140-153. |

| [13] | Daigui GUO, Yulan LIAO, Xihui ZHANG, Chengyu YUAN, Zhongye WU. Parameter Optimization and Experiment of Cassava Planter [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 122-130. |

| [14] | Qi LI, Shulin ZHANG, Dajuan ZHANG, Yingxuan JIA, Zebin WANG. Optimization of Culture Medium of Chaetoceros muelleri by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 225-233. |

| [15] | Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号