Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (9): 122-130.DOI: 10.13304/j.nykjdb.2022.0892

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Daigui GUO( ), Yulan LIAO(

), Yulan LIAO( ), Xihui ZHANG, Chengyu YUAN, Zhongye WU

), Xihui ZHANG, Chengyu YUAN, Zhongye WU

Received:2022-10-21

Accepted:2023-04-25

Online:2023-09-15

Published:2023-09-28

Contact:

Yulan LIAO

通讯作者:

廖宇兰

作者简介:郭带贵E-mail:3014349750@qq.com;

基金资助:CLC Number:

Daigui GUO, Yulan LIAO, Xihui ZHANG, Chengyu YUAN, Zhongye WU. Parameter Optimization and Experiment of Cassava Planter[J]. Journal of Agricultural Science and Technology, 2023, 25(9): 122-130.

郭带贵, 廖宇兰, 张惜辉, 袁成宇, 吴中野. 木薯种植机参数优化与试验[J]. 中国农业科技导报, 2023, 25(9): 122-130.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2022.0892

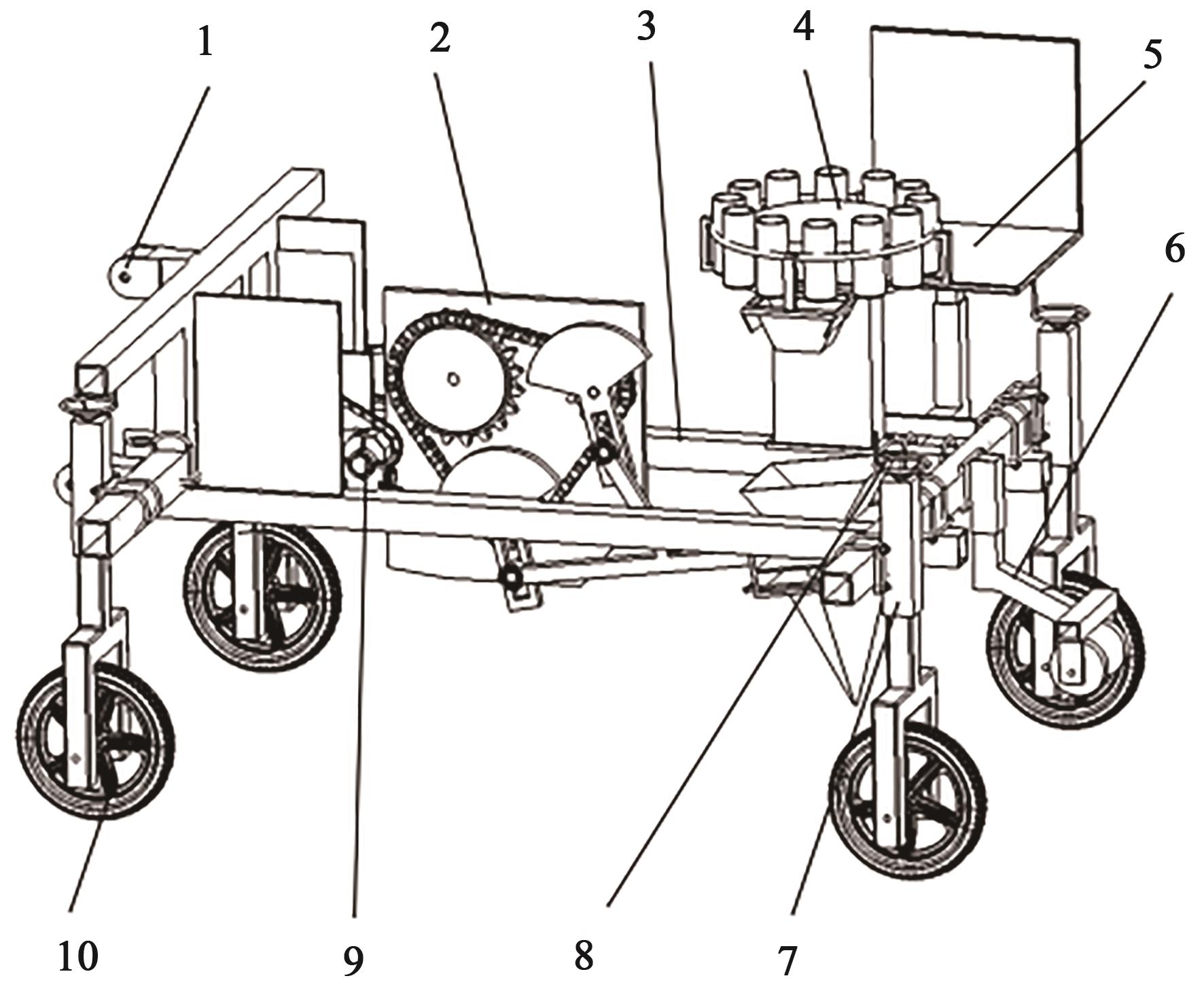

Fig. 1 Structural of cassava planterNote: 1—Three point suspension device; 2—Seeding device; 3—Rack; 4—Seeding device; 5—Seats; 6—Earth covering device; 7—Rack height adjustment device; 8—Rocker; 9—Reducer; 10—Traveling wheel.

水平 Level | 因素Factor | ||

|---|---|---|---|

A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | |

| 1 | 0.4 | 26 | 340 |

| 2 | 0.6 | 34 | 360 |

| 3 | 0.8 | 42 | 380 |

| 4 | 1.0 | 50 | 400 |

| 5 | 1.2 | 58 | 420 |

Table 1 Single-factor test levels

水平 Level | 因素Factor | ||

|---|---|---|---|

A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | |

| 1 | 0.4 | 26 | 340 |

| 2 | 0.6 | 34 | 360 |

| 3 | 0.8 | 42 | 380 |

| 4 | 1.0 | 50 | 400 |

| 5 | 1.2 | 58 | 420 |

编码 Encrypt | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm |

|---|---|---|---|

| -1 | 0.8 | 34 | 360 |

| 0 | 1.0 | 42 | 380 |

| 1 | 1.2 | 50 | 400 |

Table 2 Test factor code

编码 Encrypt | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm |

|---|---|---|---|

| -1 | 0.8 | 34 | 360 |

| 0 | 1.0 | 42 | 380 |

| 1 | 1.2 | 50 | 400 |

序号 No. | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | Y1:合格率 Qualification rate/% | Y2:漏种率 Seed leakage rate/% |

|---|---|---|---|---|---|

| 1 | 0 | -1 | 1 | 84.62 | 6.34 |

| 2 | 0 | 0 | 0 | 93.34 | 2.17 |

| 3 | -1 | -1 | 0 | 88.97 | 4.53 |

| 4 | 1 | 1 | 0 | 84.38 | 6.25 |

| 5 | 1 | 0 | -1 | 83.79 | 6.78 |

| 6 | 1 | 0 | 1 | 80.31 | 8.16 |

| 7 | 0 | 0 | 0 | 93.14 | 2.32 |

| 8 | -1 | 0 | -1 | 86.74 | 5.29 |

| 9 | 0 | 1 | 1 | 87.54 | 4.87 |

| 10 | -1 | 1 | 0 | 90.18 | 3.31 |

| 11 | 0 | 0 | 0 | 92.76 | 2.54 |

| 12 | 0 | -1 | -1 | 82.74 | 7.15 |

| 13 | 0 | 0 | 0 | 92.15 | 2.94 |

| 14 | 1 | -1 | 0 | 81.25 | 7.84 |

| 15 | 0 | 0 | 0 | 91.63 | 2.57 |

| 16 | -1 | 0 | 1 | 89.45 | 4.07 |

| 17 | 0 | 1 | -1 | 90.49 | 3.35 |

Table 3 Multi-factor combination test plan and results

序号 No. | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | Y1:合格率 Qualification rate/% | Y2:漏种率 Seed leakage rate/% |

|---|---|---|---|---|---|

| 1 | 0 | -1 | 1 | 84.62 | 6.34 |

| 2 | 0 | 0 | 0 | 93.34 | 2.17 |

| 3 | -1 | -1 | 0 | 88.97 | 4.53 |

| 4 | 1 | 1 | 0 | 84.38 | 6.25 |

| 5 | 1 | 0 | -1 | 83.79 | 6.78 |

| 6 | 1 | 0 | 1 | 80.31 | 8.16 |

| 7 | 0 | 0 | 0 | 93.14 | 2.32 |

| 8 | -1 | 0 | -1 | 86.74 | 5.29 |

| 9 | 0 | 1 | 1 | 87.54 | 4.87 |

| 10 | -1 | 1 | 0 | 90.18 | 3.31 |

| 11 | 0 | 0 | 0 | 92.76 | 2.54 |

| 12 | 0 | -1 | -1 | 82.74 | 7.15 |

| 13 | 0 | 0 | 0 | 92.15 | 2.94 |

| 14 | 1 | -1 | 0 | 81.25 | 7.84 |

| 15 | 0 | 0 | 0 | 91.63 | 2.57 |

| 16 | -1 | 0 | 1 | 89.45 | 4.07 |

| 17 | 0 | 1 | -1 | 90.49 | 3.35 |

来源 Source | 合格率Qualification rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 283.79 | 9 | 31.53 | 15.49 | 0.000 8 |

| A | 81.98 | 1 | 81.98 | 40.28 | 0.000 4 |

| B | 21.74 | 1 | 21.74 | 10.68 | 0.013 7 |

| C | 0.423 2 | 1 | 0.423 2 | 0.207 9 | 0.662 2 |

| AB | 0.921 6 | 1 | 0.921 6 | 0.452 8 | 0.522 6 |

| AC | 9.58 | 1 | 9.58 | 4.71 | 0.066 7 |

| BC | 5.83 | 1 | 5.83 | 2.87 | 0.134 3 |

| A² | 76.34 | 1 | 76.34 | 37.50 | 0.000 5 |

| B² | 23.83 | 1 | 23.83 | 11.71 | 0.011 1 |

| C² | 70.98 | 1 | 70.98 | 34.87 | 0.000 6 |

| 残差Residual | 14.25 | 7 | 2.04 | ||

| 失拟项Lack of fit | 13.43 | 4 | 3.36 | 12.25 | 0.033 5 |

| 纯误差Pure error | 0.822 3 | 3 | 0.274 1 | ||

| 总和Sum | 298.03 | 16 | |||

| R² | 0.952 2 | ||||

Table 4 Variance analysis of qualification rate

来源 Source | 合格率Qualification rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 283.79 | 9 | 31.53 | 15.49 | 0.000 8 |

| A | 81.98 | 1 | 81.98 | 40.28 | 0.000 4 |

| B | 21.74 | 1 | 21.74 | 10.68 | 0.013 7 |

| C | 0.423 2 | 1 | 0.423 2 | 0.207 9 | 0.662 2 |

| AB | 0.921 6 | 1 | 0.921 6 | 0.452 8 | 0.522 6 |

| AC | 9.58 | 1 | 9.58 | 4.71 | 0.066 7 |

| BC | 5.83 | 1 | 5.83 | 2.87 | 0.134 3 |

| A² | 76.34 | 1 | 76.34 | 37.50 | 0.000 5 |

| B² | 23.83 | 1 | 23.83 | 11.71 | 0.011 1 |

| C² | 70.98 | 1 | 70.98 | 34.87 | 0.000 6 |

| 残差Residual | 14.25 | 7 | 2.04 | ||

| 失拟项Lack of fit | 13.43 | 4 | 3.36 | 12.25 | 0.033 5 |

| 纯误差Pure error | 0.822 3 | 3 | 0.274 1 | ||

| 总和Sum | 298.03 | 16 | |||

| R² | 0.952 2 | ||||

来源 Source | 漏种率Seed leakage rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 61.75 | 9 | 6.86 | 10.90 | 0.002 4 |

| A | 17.49 | 1 | 17.49 | 27.80 | 0.001 2 |

| B | 5.90 | 1 | 5.90 | 9.37 | 0.018 3 |

| C | 0.094 6 | 1 | 0.094 6 | 0.150 3 | 0.709 7 |

| AB | 0.034 2 | 1 | 0.034 2 | 0.054 4 | 0.822 3 |

| AC | 1.69 | 1 | 1.69 | 2.69 | 0.145 3 |

| BC | 1.36 | 1 | 1.36 | 2.16 | 0.185 4 |

| A² | 16.93 | 1 | 16.93 | 26.90 | 0.001 3 |

| B² | 4.02 | 1 | 4.02 | 6.39 | 0.039 3 |

| C² | 16.02 | 1 | 16.02 | 25.45 | 0.001 5 |

| 残差Residual | 4.41 | 7 | 0.629 3 | ||

| 失拟项Lack of fit | 4.07 | 4 | 1.02 | 9.08 | 0.050 3 |

| 纯误差Pure error | 0.336 3 | 3 | 0.112 1 | ||

| 总和Sum | 66.16 | 16 | |||

| R² | 0.933 4 | ||||

Table 5 Variance analysis of seed leakage rate

来源 Source | 漏种率Seed leakage rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 61.75 | 9 | 6.86 | 10.90 | 0.002 4 |

| A | 17.49 | 1 | 17.49 | 27.80 | 0.001 2 |

| B | 5.90 | 1 | 5.90 | 9.37 | 0.018 3 |

| C | 0.094 6 | 1 | 0.094 6 | 0.150 3 | 0.709 7 |

| AB | 0.034 2 | 1 | 0.034 2 | 0.054 4 | 0.822 3 |

| AC | 1.69 | 1 | 1.69 | 2.69 | 0.145 3 |

| BC | 1.36 | 1 | 1.36 | 2.16 | 0.185 4 |

| A² | 16.93 | 1 | 16.93 | 26.90 | 0.001 3 |

| B² | 4.02 | 1 | 4.02 | 6.39 | 0.039 3 |

| C² | 16.02 | 1 | 16.02 | 25.45 | 0.001 5 |

| 残差Residual | 4.41 | 7 | 0.629 3 | ||

| 失拟项Lack of fit | 4.07 | 4 | 1.02 | 9.08 | 0.050 3 |

| 纯误差Pure error | 0.336 3 | 3 | 0.112 1 | ||

| 总和Sum | 66.16 | 16 | |||

| R² | 0.933 4 | ||||

指标 Indicator | 合格率 Qualification rate/% | 漏种率 Seed leakage rate/% |

|---|---|---|

试验平均值 Test average | 95.47 | 2.05 |

优化值 Optimization value | 93.85 | 1.96 |

相对误差 Relative error | 1.73 | 4.60 |

Table 6 Verification result

指标 Indicator | 合格率 Qualification rate/% | 漏种率 Seed leakage rate/% |

|---|---|---|

试验平均值 Test average | 95.47 | 2.05 |

优化值 Optimization value | 93.85 | 1.96 |

相对误差 Relative error | 1.73 | 4.60 |

| 1 | 梁海波,黄洁,安飞飞,等.中国木薯产业现状分析[J].江西农业学报,2016, 28(6):22-26. |

| LIANG H B, HUANG J, AN F F, et al.. Analysis of cassava industry in China [J]. Jiangxi Agric. J., 2016, 28(6): 22-26. | |

| 2 | 陈林涛,牟向伟,薛俊祥,等.国内外木薯机械化种收装备研究现状与展望[J].农业工程,2022,12(2):10-16. |

| CHEN L T, MOU X W, XUE J X, et al..Research status and prospect of cassava mechaninzed planting and harvesting equipment at home and abroad [J]. Agric. Eng., 2022, 12(2):10-16. | |

| 3 | 覃双眉,李明.国内外木薯种植机械研究进展[J].安徽农业科学, 2011, 39(8): 5016-5018. |

| QIN S M, LI M. Research progress of cassava planting machinery at home and abroad [J]. J. Anhui Agric. Sci., 2011, 39(8): 5016-5018. | |

| 4 | 李玲,林晴,邓干然,等.实时切种式木薯种植机漏播监测标记系统设计与试验[J].农机化研究, 2023(1):78-83. |

| LI L, LIN Q, DENG G R, et al.. Design and test of real-time leakage sowing monitoring and marking system for seed-cutting cassava planter [J]. J. Agric. Mechan. Res., 2023(1):78-83. | |

| 5 | 梁欣锐.广西木薯机械化生产关键技术研究[J].广西农业机械化,2015(1):29-31. |

| LIANG X R. Research on the key technology of cassava mechanized production in Guangxi [J]. Guangxi Agric. Mechan., 2015(1):29-31. | |

| 6 | 杨怡,廖宇兰,郑侃,等.木薯田间机械化作业研究现状分析[J].广东农业科学, 2015,42(8):137-140. |

| YANG Y, LIAO Y L, ZHENG K, et al.. Analysis of the current status of mechanized operation in cassava field [J]. Guangdong Agric. Sci., 2015, 42(8):137-140. | |

| 7 | 蒋瑞,黄晖,崔振德.国内外木薯机械化种植技术的研究现状和发展动态[J]. 中国热带农业,2012(3):58-60. |

| JIANG R, HUANG H, CUI Z D. Research status and development trends of cassava mechanized planting technology at home and abroad [J]. China Tropical Agric., 2012(3):58-60. | |

| 8 | 崔振德,邓干然,李玲,等.木薯垄作模式下起垄技术与设备研究进展[J].热带农业工程,2018,42(4):12-16. |

| CUI Z D, DENG G R, LI L, et al.. Research advances of ridging technology and equipment under cassava ridge cuiture model [J]. Trop. Agric. Eng., 2018, 42(4):12-16. | |

| 9 | LUNGKAPIN J, SALOKHE V M, KALSIRISILP R, et al.. Development of a stem cutting unit for a cassava planter [J]. Agric. Eng. Int.: CIGR J., 2007, 9 (4) : 1-16. |

| 10 | LUNGKAPIN J, SALOKHE V M, KALSIRISILP R, et al.. Design and development of a cassava planter [J]. Trans. ASABE, 2009, 52(2):394-399. |

| 11 | OSPINA B, CADAVID L F, MARTHA G,et al.. Mechanizatin possibilities for cassava production in Colombia [C] // Proceedings of the Seventh Regional Workshop Held in Bangkok. Thailand: 2007: 277-287. |

| 12 | 邵仁清,关意昭,周世英.2BMSU/2X旋切开沟式木薯播种机的研制[J].广西农业机械化, 2014(4):34-36. |

| SHAO R Q, GUAN Y Z, ZHOU S Y. Development of 2BMSU/2X rotary cutting and ditching cassava planter [J]. Guangxi Agric. Mechan., 2014(4):34-36. | |

| 13 | 曾伯胜,叶才学,鲁华. 2CMS-2型木薯联合种植机的研究设计[J].广西农业机械化,2011(6):21-22. |

| ZENG B S, YE C X, LU H. Research and design of 2CMS-2 cassava combine planter [J]. Guangxi Agric. Mechan., 2011(6):21-22. | |

| 14 | 崔振德,邓干然,郑爽,等.一种宽窄双行起垄式木薯种植机:CN201910141574.3[P]. 2019-05-14. |

| 15 | 刘炳先,廖宇兰,熊佳,等.木薯收获机抖动链式筛土装置的设计与实验[J].农机化研究,2020,42(6):41-45. |

| LIU B X, LIAO Y L, XIONG J, et al.. Desigh and experiment of dither chain sieving soil device for cassava harvester [J]. J. Agric. Mechan. Res., 2020,42(6):41-45. | |

| 16 | 金鑫,杜新武,杨传华,等.移栽机曲柄滑槽式栽植机构设计与试验[J].农业机械学报, 2016, 47(5):83-90. |

| JIN X, DU X W, YANG C H, et al.. Design and experiment on crank-chute planting mechanism of transplanting machine [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(5):12-21. | |

| 17 | 韩长杰,徐阳,尤佳,等.半自动压缩基质型西瓜钵苗移栽机成穴器参数优化[J].农业工程学报,2019,35(11):48-56. |

| HAN C J, XU Y, YOU J, et al.. Parameter optimization of opener of semi-automatic transplanter for watermelon seedlings raised oncompression substrate [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(11): 48-56. | |

| 18 | 薛忠,张秀梅,陈如约,等.2ZBL-90双行菠萝种植机设计与试验[J].中国农机化学报, 2022, 43(6):9-14. |

| XUE Z, ZHANG X M, CHEN R Y, et al.. Design and experiment of 2ZBL-90 double row pineapple planter [J]. J. Chin. Agric. Mechan., 2022,43(6): 9-14. | |

| 19 | 任露泉.试验设计及其优化[M].北京:科学出版社, 2009:1-259. |

| 20 | 张成军.实验设计与数据处理[M].北京:化学工业出版社,2009:1-175. |

| 21 | 刘智豪,石佳磊,郭朝阳,等.基于Solid Works的装盘式沙漠种植机设计[J].科技创新与应用,2023,13(9):18-21. |

| LIU Z H, SHI J L, GUO C Y, et al.. Design of loading desert planter based on Solid Works [J]. Tech. Innov. Appl., 2023,13(9):18-21. | |

| 22 | 黄柳益.预切种式甘蔗横向种植机开沟器结构优化[J].农业与技术, 2021,41(21):44-47. |

| HUANG L Y. Optimize the structure of pre-cut sugarcane transverse planter [J]. Agric. Technol., 2021,41(21):44-47. |

| [1] | Haidong ZHANG, Zhixian TANG, Liyun ZHANG, Qi YU, Chaojun SONG. Optimization of Discrete Elemental Simulation Parameters for Forest Panax pseudoginseng Plantation Red Soil Based on GA-BP-GA [J]. Journal of Agricultural Science and Technology, 2025, 27(9): 120-130. |

| [2] | Shuoshuo FU, Weiyong GONG, Yixuan LIN, Yuanshun LI, Chengcan LIU, Lin NI. Optimization of Extraction Technology and Antifungal Activity of Total Diterpene from Fokienia Hodginsii [J]. Journal of Agricultural Science and Technology, 2025, 27(5): 146-155. |

| [3] | Chunlin MIAO, Huanhuan XU, Ziyi JIA, Aimin HE, Yangyang JI, Dehua MOU, Shan GAO. Oxidation Resistance Analysis and Component Identification of Distracted Wood Water Extracts [J]. Journal of Agricultural Science and Technology, 2025, 27(5): 182-192. |

| [4] | Zhongzhong DOU, Yiqi LIU. Simulation Analysis of Arc-jaw Type Potato Precision Seed Discharger [J]. Journal of Agricultural Science and Technology, 2025, 27(4): 110-119. |

| [5] | Changlong FENG, Chenyang NING, Yixin ZHU, Shuping LI, Chunguang HUANG. Research on Design and Optimization of Ring Winding Mechanism for Trunk Bandages [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 122-132. |

| [6] | Ruyan ZHANG, Shenhao LI, Qipeng ZHU, Taigang FENG, Hongbo LI, Zebing XING, Yu XIAN. Effect of Biochar Content on Physical and Mechanical Properties of Garden Greening Waste/polylactic Acid Composites [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 192-200. |

| [7] | Changlong FENG, Chunguang HUANG, Chenyang NING, Shuping LI, Kejin CHEN. Optimization of Performance and Characteristics of Spiral Drill Bit Excavation Mechanism for Planting Machine [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 89-98. |

| [8] | Xue WANG, Xing ZHENG, Jiamiao REN, Yazhou ZHAO, Wenjun PENG. Optimization of Extraction Conditions for Volatile Components in Jujube Honey Based on Plackett-Burman Design and Response Surface Method [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 181-192. |

| [9] | Jingyi XI, Shuangqing WANG, Yitong BAI, Xiuli YAO, Bixuan HUANG, Qingyi LI, Liqing FAN, Shichen HUANG, Mingguo SUN. Study on Optimization of Processing Parameters Using Hermetia illucens Larva to Treat Food Waste by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 241-249. |

| [10] | Lijun FU, Xiaoyu LIN, Jianhua LIN, Huinan SHEN, Yongzhen WU. Research on Processing Technology and Shelf Life of Red Matsutake Beef Sauce [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 148-158. |

| [11] | Lanxiong ZHANG, Wei ZHENG, Yuan’an CHEN, Jing SHEN, Shuangquan ZOU, Jianrong WU, Lin NI. Study on Extraction Process and Antibacterial Activity of Lignans from Cinnamomum camphora Leaves [J]. Journal of Agricultural Science and Technology, 2024, 26(5): 138-147. |

| [12] | Dongling LIU, Hao SI, Baojiang ZHENG, Yuhong ZHANG. Optimization of Enzyme Assisted-ultrasonic Extraction of Sinigrin in Thlaspi arvense Seeds by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 225-233. |

| [13] | Lei JI, Hongyan LI, Ying WANG, Xiaodong JIANG, Tianhong LIU, Xiao LI, Yuanqin SUN, Hongjun LIU. Optimization of Processing Technology and Analysis of Aroma Components of Tomato Flavored Puffed Shrimp Slices [J]. Journal of Agricultural Science and Technology, 2024, 26(1): 140-153. |

| [14] | Qi LI, Shulin ZHANG, Dajuan ZHANG, Yingxuan JIA, Zebin WANG. Optimization of Culture Medium of Chaetoceros muelleri by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(8): 225-233. |

| [15] | Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号