中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (9): 99-109.DOI: 10.13304/j.nykjdb.2024.0147

杜雪林1( ), 刘颖1, 邹家华1, 涂宇2(

), 刘颖1, 邹家华1, 涂宇2( ), 周灿1, 程晋鹏1

), 周灿1, 程晋鹏1

收稿日期:2024-03-01

接受日期:2024-03-22

出版日期:2025-09-15

发布日期:2025-09-24

通讯作者:

杜雪林,涂宇

作者简介:杜雪林 E-mail:du_xuelin@126.com基金资助:

Xuelin DU1( ), Ying LIU1, Jiahua ZOU1, Yu TU2(

), Ying LIU1, Jiahua ZOU1, Yu TU2( ), Can ZHOU1, Jinpeng CHENG1

), Can ZHOU1, Jinpeng CHENG1

Received:2024-03-01

Accepted:2024-03-22

Online:2025-09-15

Published:2025-09-24

Contact:

Xuelin DU,Yu TU

摘要:

智能分类垃圾处理装置可将垃圾自动识别分类,归类为可回收垃圾、有害垃圾、厨余垃圾和其他垃圾等。针对餐厨垃圾粉碎处理问题,利用SolidWorks设计破壁机粉碎机构和双齿辊粉碎机构,在EDEM中建立餐厨垃圾的离散元颗粒黏结模型,并基于2种粉碎机构进行仿真试验。结果显示,破壁机机构粉碎的小颗粒占比更高,如仿真试验中对于粉碎对象1和粉碎对象2的小颗粒占比分别为86.2%和39.9%,仿真试验和样机试验所得颗粒占比基本一致,误差不超过5%。由此可见,破壁机粉碎机构的粉碎效果优于双齿辊粉碎机构。以上研究结果为餐厨垃圾渣液分离处理装置设计提供参考。

中图分类号:

杜雪林, 刘颖, 邹家华, 涂宇, 周灿, 程晋鹏. 双齿辊粉碎机构和破壁机粉碎机构对餐厨垃圾的粉碎效果[J]. 中国农业科技导报, 2025, 27(9): 99-109.

Xuelin DU, Ying LIU, Jiahua ZOU, Yu TU, Can ZHOU, Jinpeng CHENG. Crushing Effect of Double Tooth Roller Crushing Mechanism and Wall Breaker Crushing Mechanism on Kitchen Waste[J]. Journal of Agricultural Science and Technology, 2025, 27(9): 99-109.

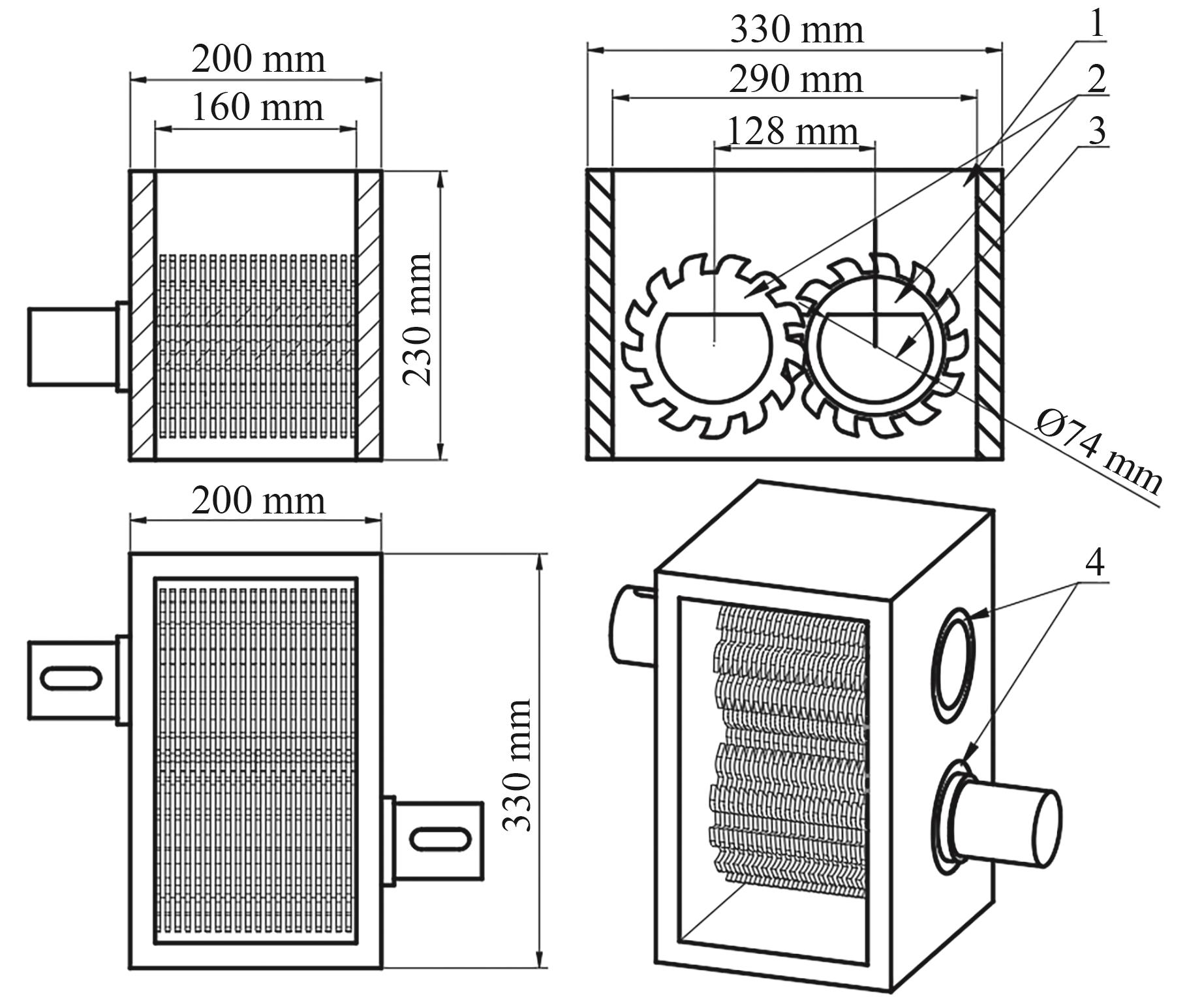

图3 双齿辊机构整体结构注:1—箱体;2—破碎刀齿和隔套;3—传动轴;4—深沟球轴承。

Fig. 3 Overall structure of double-tooth roller mechanismNote: 1—Box part; 2—Crusher teeth and spacer sleeve; 3—Drive shaft; 4—Deep groove ball bearings.

| 因素Factor | 对象1 Object 1 | 对象2 Object 2 |

|---|---|---|

| 单位面积法向刚度Normal stiffness per unit area/(N·m-3) | 12.50×107 | 6.25×108 |

| 单位面积剪切刚度Shear stiffness per unit area/(N·m-3) | 10.00×107 | 4.16×108 |

| 抗拉强度Tensile strength/MPa | 4.40 | 6.42 |

| 抗剪强度Shear strength/MPa | 2.2 | 7.7 |

| 黏合半径Bonding radius/mm | 1.5 | 0.8 |

表1 粉碎对象接触模型参数

Table 1 Contact model parameters of crushing objects

| 因素Factor | 对象1 Object 1 | 对象2 Object 2 |

|---|---|---|

| 单位面积法向刚度Normal stiffness per unit area/(N·m-3) | 12.50×107 | 6.25×108 |

| 单位面积剪切刚度Shear stiffness per unit area/(N·m-3) | 10.00×107 | 4.16×108 |

| 抗拉强度Tensile strength/MPa | 4.40 | 6.42 |

| 抗剪强度Shear strength/MPa | 2.2 | 7.7 |

| 黏合半径Bonding radius/mm | 1.5 | 0.8 |

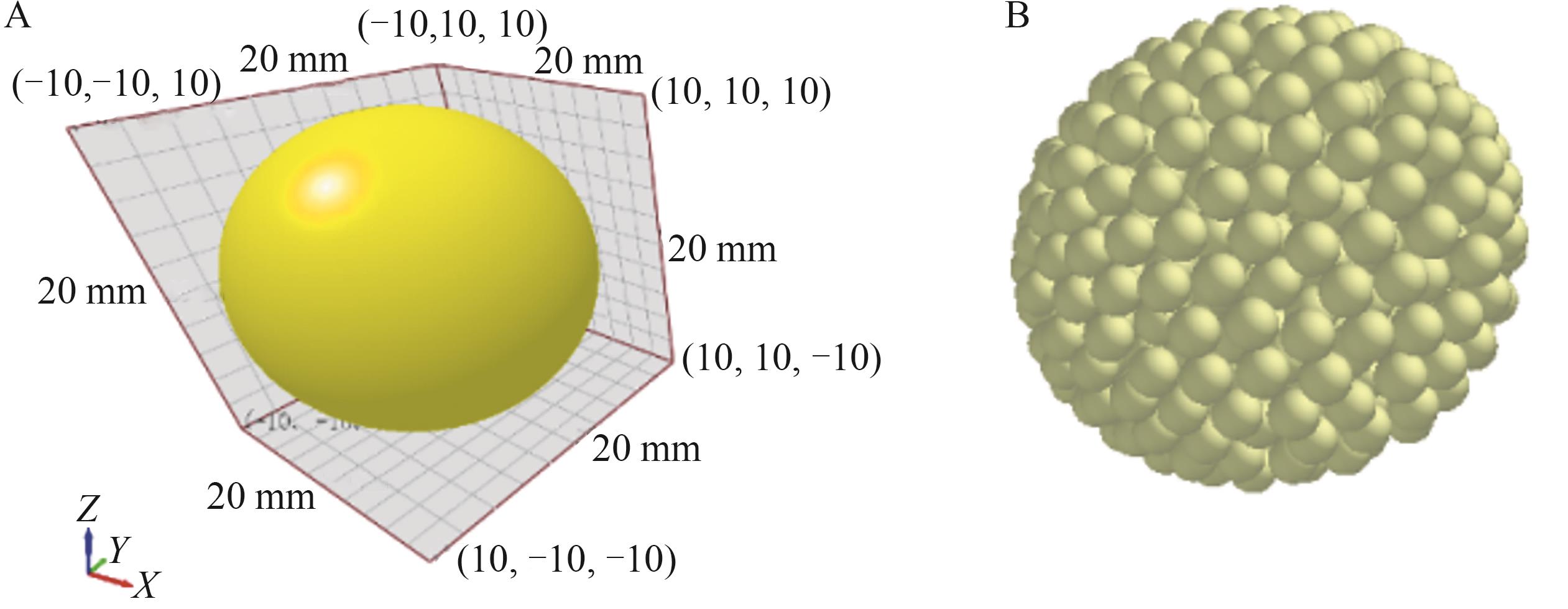

图5 粉碎对象1的颗粒黏结模型A:粉碎对象1颗粒尺寸;B:填充后粉碎对象1的轮廓

Fig. 5 Particle bonding model for crushing object 1A: Particle size of object 1;B: Outline of object 1 after filling

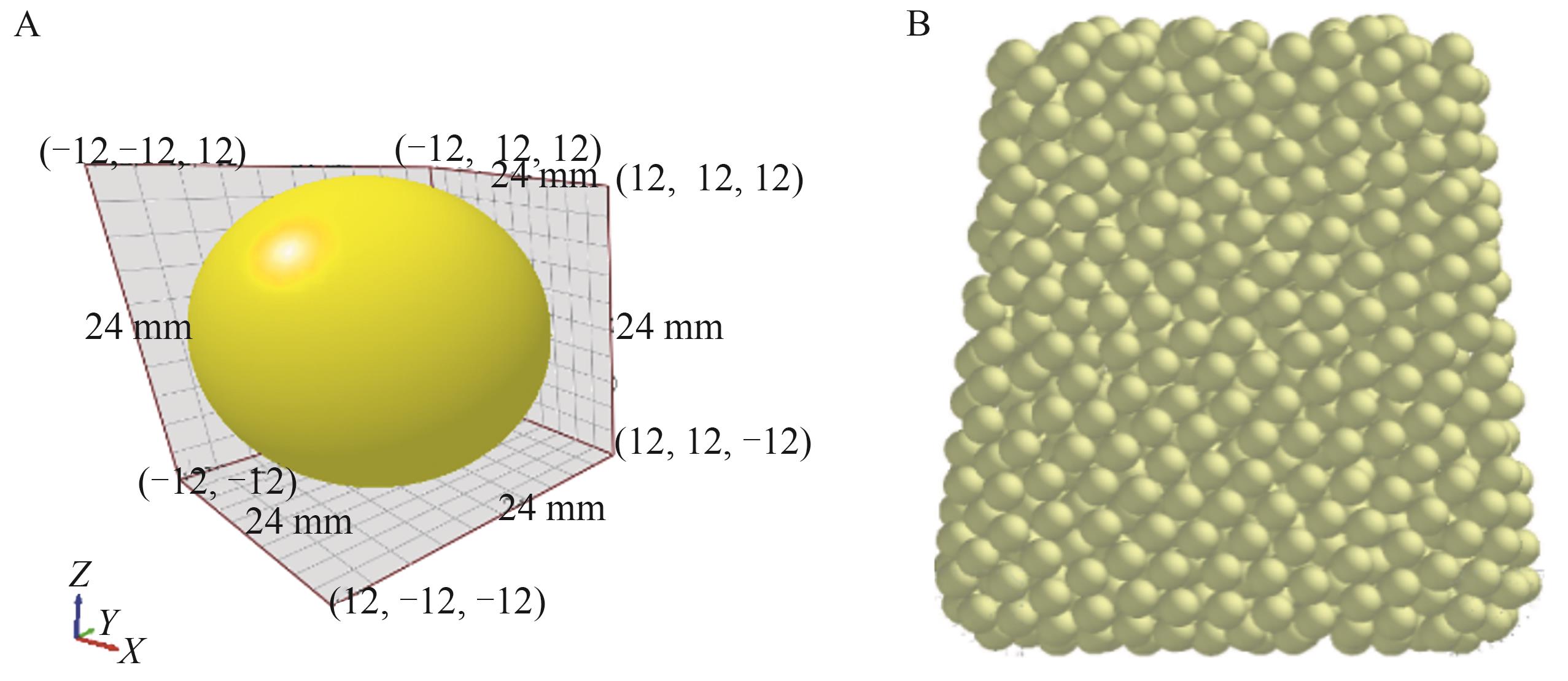

图6 粉碎对象2的颗粒黏结模型A:粉碎对象2颗粒尺寸;B:填充后粉碎对象2的轮廓

Fig. 6 Particle bonding model for crushing object 2A: Particle size of object 2;B: Outline of object 2 after filling

参数 Parameter | 对象1 Object 1 | 对象2 Object 2 | ||

|---|---|---|---|---|

| 物料Material | 钢板Steel plate | 物料Material | 钢板Steel plate | |

| 泊松比Poisson’s ratio | 0.49 | 0.30 | 0.40 | 0.30 |

| 剪切模量Shear modulus/MPa | 1.89 | 70 000.00 | 311.40 | 70 000.00 |

| 密度Density/(kg·m-3) | 1 200 | 7 800 | 1 197 | 7 800 |

物料与物料恢复系数 Recovery coefficient of material and material | 0.900 | 0.284 | ||

物料与钢板恢复系数 Recovery coefficient of material and steel plate | 0.300 | 0.615 | ||

物料与物料静摩擦系数 Static friction coefficient between materials | 0.500 | 0.342 | ||

物料与钢板静摩擦系数 Static friction coefficient between material and steel plate | 0.500 | 0.467 | ||

物料与物料滑动摩擦系数 Sliding friction coefficient between materials | 0.100 0 | 0.054 5 | ||

物料与钢板滑动摩擦系数 Sliding friction coefficient between material and steel plate | 0.010 0 | 0.031 7 | ||

表2 粉碎对象1和2的特性参数[23-24]

Table 2 Material characteristic parameters for crushing object 1 and object 2[23-24]

参数 Parameter | 对象1 Object 1 | 对象2 Object 2 | ||

|---|---|---|---|---|

| 物料Material | 钢板Steel plate | 物料Material | 钢板Steel plate | |

| 泊松比Poisson’s ratio | 0.49 | 0.30 | 0.40 | 0.30 |

| 剪切模量Shear modulus/MPa | 1.89 | 70 000.00 | 311.40 | 70 000.00 |

| 密度Density/(kg·m-3) | 1 200 | 7 800 | 1 197 | 7 800 |

物料与物料恢复系数 Recovery coefficient of material and material | 0.900 | 0.284 | ||

物料与钢板恢复系数 Recovery coefficient of material and steel plate | 0.300 | 0.615 | ||

物料与物料静摩擦系数 Static friction coefficient between materials | 0.500 | 0.342 | ||

物料与钢板静摩擦系数 Static friction coefficient between material and steel plate | 0.500 | 0.467 | ||

物料与物料滑动摩擦系数 Sliding friction coefficient between materials | 0.100 0 | 0.054 5 | ||

物料与钢板滑动摩擦系数 Sliding friction coefficient between material and steel plate | 0.010 0 | 0.031 7 | ||

粉碎对象 Crushing object | 粉碎机 Crusher | 生成bond键数量 Number of generated bonds | 破碎bond键数量 Number of broken bonds | 破碎键占比 Proportion of broken bonds/% |

|---|---|---|---|---|

对象1 Object 1 | 双齿辊粉碎机 Double-tooth roller crusher | 66 397 | 46 575 | 70.1 |

| 破壁机粉碎机Wall-breaking crusher | 69 899 | 63 135 | 90.3 | |

对象2 Object 2 | 双齿辊粉碎机 Double-tooth roller crusher | 54 040 | 22 804 | 42.2 |

| 破壁机粉碎机Wall-breaking crusher | 53 998 | 32 347 | 59.9 |

表3 粉碎前后的bond键数量

Table 3 Number of bond keys before and after crushing

粉碎对象 Crushing object | 粉碎机 Crusher | 生成bond键数量 Number of generated bonds | 破碎bond键数量 Number of broken bonds | 破碎键占比 Proportion of broken bonds/% |

|---|---|---|---|---|

对象1 Object 1 | 双齿辊粉碎机 Double-tooth roller crusher | 66 397 | 46 575 | 70.1 |

| 破壁机粉碎机Wall-breaking crusher | 69 899 | 63 135 | 90.3 | |

对象2 Object 2 | 双齿辊粉碎机 Double-tooth roller crusher | 54 040 | 22 804 | 42.2 |

| 破壁机粉碎机Wall-breaking crusher | 53 998 | 32 347 | 59.9 |

粉碎对象 Crushing object | 颗粒类型 Particle type | 占比Percentage/% | |

|---|---|---|---|

破壁机粉碎机 Wall-breaking crusher | 双齿辊粉碎机 Double-tooth roller crusher | ||

对象1 Object 1 | 大颗粒Large particle | 5.9 | 52.9 |

| 中颗粒Medium particle | 7.7 | 29.7 | |

| 小颗粒Small particle | 86.2 | 17.3 | |

对象2 Object 2 | 大颗粒Large particle | 33.7 | 50.1 |

| 中颗粒Medium particle | 26.4 | 42.8 | |

| 小颗粒Small particle | 39.9 | 7.1 | |

表4 2种粉碎机粉碎后不同颗粒的占比

Table 4 Percentage of different sizes of particle after crushing by two types of crushers

粉碎对象 Crushing object | 颗粒类型 Particle type | 占比Percentage/% | |

|---|---|---|---|

破壁机粉碎机 Wall-breaking crusher | 双齿辊粉碎机 Double-tooth roller crusher | ||

对象1 Object 1 | 大颗粒Large particle | 5.9 | 52.9 |

| 中颗粒Medium particle | 7.7 | 29.7 | |

| 小颗粒Small particle | 86.2 | 17.3 | |

对象2 Object 2 | 大颗粒Large particle | 33.7 | 50.1 |

| 中颗粒Medium particle | 26.4 | 42.8 | |

| 小颗粒Small particle | 39.9 | 7.1 | |

图12 2种粉碎机粉碎物料后处理过程A~D:双齿辊粉碎机构粉碎对象1处理模型;E~H:破壁机粉碎机构粉碎对象1处理模型;I~L:双齿辊粉碎机构粉碎对象2处理模型;M~P: 破壁机粉碎机构粉碎对象2处理模型

Fig. 12 Post processing of materials crushed by two types of crushersA~D: Processing model of double toothed roller crushing mechanism for object 1; E~H: Processing model of wall breaking crushing mechanism for object 1; I~L: Processing moel of double toothed roller crushing mechanism for object 2; M~P: Processing model of wall breaking crushing mechanism for object 2

参数 Parameter | 双齿辊粉碎机Double-tooth roller crusher | 破壁机粉碎机Wall-breaking crusher | ||

|---|---|---|---|---|

| 对象1 Object 1 | 对象2 Object 2 | 对象1 Object 1 | 对象2 Object 2 | |

破碎前表面积 Surface area before crushing/mm² | 1 070.51 | 641.78 | 1 108.46 | 582.47 |

破碎后表面积 Surface area after crushing/mm² | 2 219.90 | 1 106.95 | 2 492.77 | 1 054.12 |

破碎前总质量 Total mass before crushing/g | 23.46 | 7.94 | 23.96 | 7.82 |

破碎后总质量 Total mass after crushing/g | 22.79 | 7.11 | 22.12 | 6.80 |

大颗粒质量 Mass of large particles/g | 11.55 | 3.30 | 2.10 | 2.32 |

中颗粒质量 Mass of medium particles/g | 6.54 | 3.03 | 1.82 | 1.64 |

小颗粒质量 Mass of small particles/g | 4.70 | 0.78 | 18.20 | 2.84 |

大颗粒占比 Percentage of large particles/% | 51.0 | 46.4 | 9.5 | 34.1 |

中颗粒占比 Percentage of Medium particles/% | 28.7 | 42.6 | 8.2 | 24.1 |

小颗粒占比 Percentage of small particles/% | 20.6 | 10.9 | 82.3 | 41.8 |

表5 2种粉碎机构样机的粉碎结果

Table 5 Crushing result of two types of crushers

参数 Parameter | 双齿辊粉碎机Double-tooth roller crusher | 破壁机粉碎机Wall-breaking crusher | ||

|---|---|---|---|---|

| 对象1 Object 1 | 对象2 Object 2 | 对象1 Object 1 | 对象2 Object 2 | |

破碎前表面积 Surface area before crushing/mm² | 1 070.51 | 641.78 | 1 108.46 | 582.47 |

破碎后表面积 Surface area after crushing/mm² | 2 219.90 | 1 106.95 | 2 492.77 | 1 054.12 |

破碎前总质量 Total mass before crushing/g | 23.46 | 7.94 | 23.96 | 7.82 |

破碎后总质量 Total mass after crushing/g | 22.79 | 7.11 | 22.12 | 6.80 |

大颗粒质量 Mass of large particles/g | 11.55 | 3.30 | 2.10 | 2.32 |

中颗粒质量 Mass of medium particles/g | 6.54 | 3.03 | 1.82 | 1.64 |

小颗粒质量 Mass of small particles/g | 4.70 | 0.78 | 18.20 | 2.84 |

大颗粒占比 Percentage of large particles/% | 51.0 | 46.4 | 9.5 | 34.1 |

中颗粒占比 Percentage of Medium particles/% | 28.7 | 42.6 | 8.2 | 24.1 |

小颗粒占比 Percentage of small particles/% | 20.6 | 10.9 | 82.3 | 41.8 |

| [1] | 田维平,邢宇,王周强,等.黑水虻处理城镇污泥和餐厨垃圾的性能评价[J].中国环境科学,2024,44(8):4425-4431. |

| TIAN W P, XING Y, WANG Z Q, et al.. Performance evaluation for the treatment of municipal sludge and kitchen waste via black solider fly larvae [J]. China Environ. Sci., 2024, 44(8): 4425-4431. | |

| [2] | WANG N, LI G, ZHANG H M, et al.. Design and research of home automatic kitchen waste composting device [J/OL]. E3S Web Confer., 2019, 136(7): 04013 [2024-02-10]. . |

| [3] | 王琬,孙远波,孙大禹.一种新型厨余垃圾自动处理系统设计[J].机械科学与技术, 2013, 32(7): 1046-1048. |

| WANG W, SUN Y B, SUN D Y. The design of a new type of automatic processing system for kitchen waste [J]. Mech. Sci. Technol. Aerosp. Eng., 2013, 32(7): 1046-1048. | |

| [4] | FENG Z C, YANG J, CHEN L F, et al.. An intelligent waste-sorting and recycling device based on improved efficient net [J/OL]. Int. J. Environ. Res. Public Health, 2022, 19:15987 [2024-02-10]. . |

| [5] | 蔡传钰.农村生活垃圾分类与资源化处理技术研究[D].杭州: 浙江大学, 2012. |

| CAI C Y. Study on applicable technology for rural solid waste classification and recycling [D]. Hangzhou: Zhejiang University, 2012. | |

| [6] | 张代湘.关于粉碎理论的论述[J].西北轻工业学院学报,1983,1(2):16-19. |

| [7] | SUN K K, MA R D, LI G, et al.. The influence of the structure of double toothed roller crusher on the crushing effect based on EDEM [J/OL]. IOP Conf. Ser. Mater. Sci. Eng., 2018, 423:012152 [2024-02-10]. . |

| [8] | 范国强,王忠宇,王保兴,等.旋筒供料锤式饲草粉碎机设计与试验[J].农业机械学报,2021,52(12):43-53, 76. |

| FAN G Q, WANG Z Y, WANG B X, et al.. Design and experiment of rotary feed tube hammer grinder [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(12): 43-53, 76. | |

| [9] | 丁桐桐,徐建华,李远安,等.基于离散单元法的立轴冲击破碎机成砂率数值计算[J].应用力学学报,2021,38(5):2018-2024. |

| DING T T, XU J H, LI Y A, et al.. Numerical calculation of sand formation rate of vertical shaft impact crusher based on discrete element method [J]. Chin. J. Appl. Mech., 2021, 38(5): 2018-2024. | |

| [10] | 刘进,马立峰,王志霞,等.基于EDEM的旋回破碎机能耗模型研究[J].煤炭工程,2023,55(2):152-157. |

| LIU J, MA L F, WANG Z X, et al.. Energy consumption model of gyratory crusher based on EDEM [J]. Coal Eng., 2023, 55(2): 152-157. | |

| [11] | 毛君,刘歆妍,陈洪月,等.基于EDEM的采煤机滚筒工作性能的仿真研究[J].煤炭学报,2017,42(4):1069-1077. |

| MAO J, LIU X Y, CHEN H Y, et al.. Simulation of shearer drum cutting performance based on EDEM [J]. J. China Coal Soc., 2017, 42(4): 1069-1077. | |

| [12] | 刘煜, 郑群飞.基于离散元素法的双齿辊破碎机影响因素研究[J].矿业科学学报,2018,3(4):364-370. |

| LIU Y, ZHENG Q F. Study on the influence factors of the double-geared roller crusher based on the discrete element method [J]. J. Min. Sci. Technol., 2018, 3(4): 364-370. | |

| [13] | 李强,巩亚东,宋伟刚.基于物料运动特性的旋回破碎机生产率分析[J].中国机械工程,2016,27(15):2034-2039. |

| LI Q, GONG Y D, SONG W G. Gyratory crusher productivity analysis based on kinematic characteristics of materials [J]. China Mech. Eng., 2016, 27(15): 2034-2039. | |

| [14] | FENG F, SHI J, YANG J, et al.. Correlation between the angle of the guide plate and crushing performance in vertical shaft crushers [J/OL]. Shock. Vib., 2022, 2022(1): 9991855 [2024-02-10]. . |

| [15] | XU Y, ZHANG X, WU S, et al.. Numerical simulation of particle motion at cucumber straw grinding process based on EDEM [J/OL]. Int. J. Agric. Biol. Eng., 2020, 13(6):5452 [2024-02-10]. . |

| [16] | 吴硕,李萍萍,张西良,等.基于离散元法的番茄秸秆立式螺旋混合机理[J].排灌机械工程学报, 2018, 36(8): 719-724. |

| WU S, LI P P, ZHANG X L, et al.. Vertical spiral mixing mechanism of tomato straw particles based on discrete element method [J]. J. Drain. Irrig. Mach. Eng., 2018, 36(8): 719-724. | |

| [17] | 张强,张旭,孙绍安.基于EDEM的家用榨油机压榨腔工作性能仿真研究[J].农业工程学报,2018,34(24):283-291. |

| ZHANG Q, ZHANG X, SUN S A. Simulation study on working performance of pressing cavity of household oil press based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(24): 283-291. | |

| [18] | CHENG Q, WANG J X, LIU K. Design of rice straw fiber crusher and evaluation of fiber quality [J]. Agriculture, 2022, 12(5): 1-17. |

| [19] | 袁晓明,王超,阎鹏,等.离散元法在工农业上的应用研究综述[J].机械设计,2016,33(9):1-9. |

| YUAN X M, WANG C, YAN P, et al.. Review of discrete element method in industrial and agricultural applications [J]. J. Mach. Des., 2016, 33(9): 1-9. | |

| [20] | 王浩璇,果霖,王一鸣,等.基于EDEM-Fluent仿真的餐厨垃圾渣液分离机设计与试验[J].食品与机械,2021,37(1):130-136. |

| WANG H X, GUO L, WANG Y M, et al.. Design and test of the separator of kitchen waste residue liquid based on EDEM- Fluent simulation [J]. Food Mach., 2021, 37(1): 130-136. | |

| [21] | POTYONDY D, CUNDALL P. A bonded-particle model for rock [J]. Int. J. Rock Mech. Min. Sci., 2004, 41(8): 1329-1364. |

| [22] | 王国强,郝万军,王继新.离散单元法及其在EDEM上的实践[M].西安:西北工业大学出版社,2010:1-118. |

| [23] | 王美美,王万章,杨立权,等.基于EDEM的玉米子粒建模方法的研究[J].河南农业大学学报,2018,52(1):80-84, 103. |

| WANG M M, WANG W Z, YANG L Q, et al.. Research of discrete element modeling method of maize kernel based on EDEM [J]. J. Henan Agric. Univ., 2018, 52(1): 80-84, 103. | |

| [24] | 李凯锋,杨炳南,杨德秋,等.胡萝卜物理力学特性的试验研究[J].农机化研究,2016,38(5):169-175, 180. |

| LI K F, YANG B N, YANG D Q, et al.. Experimental research on physical and mechanical properties of carrot [J]. J. Agric. Mech. Res., 2016, 38(5): 169-175, 180. |

| [1] | 郗婧怡, 王双庆, 白一彤, 姚秀利, 黄碧璇, 李青怡, 范丽清, 黄世臣, 孙明国. 响应面法优化黑水虻处理餐厨垃圾工艺参数研究[J]. 中国农业科技导报, 2025, 27(1): 241-249. |

| [2] | 张丽珍, 朱倓. 离心式投饲机抛料盘对饲料破碎率的影响[J]. 中国农业科技导报, 2023, 25(6): 107-116. |

| [3] | 于淼, 周海宾, 丁京涛, 程红胜, 沈玉君, 范盛远, 张曦, 王健, 徐鹏翔, 程琼仪. 基于EDEM的餐厨垃圾组成颗粒间接触参数标定[J]. 中国农业科技导报, 2023, 25(12): 111-120. |

| [4] | 宋世圣, 孙松林, 方芹, 彭才望, 周婷, 朱海英. 黑水虻生物转化餐厨垃圾有机肥离散元模型参数标定[J]. 中国农业科技导报, 2022, 24(6): 123-132. |

| [5] | 唐楠锐, 周勇, 张国忠, 梁方, 柯烩彬. 搅种型孔式水稻穴播排种器的性能模拟与试验[J]. 中国农业科技导报, 2022, 24(4): 107-115. |

| [6] | 胡婷, 全伟, 吴明亮, 李林. 双垄四行花生垄作播种机种沟开沟器设计与试验[J]. 中国农业科技导报, 2021, 23(9): 129-137. |

| [7] | 尹靖凯, 龚小燕, 孙丽娜, 韩梦琦, 杨渊, 徐晓燕, 王小波. 黑水虻对餐厨垃圾养分转化研究[J]. 中国农业科技导报, 2021, 23(6): 154-159. |

| [8] | 顿国强1,于春玲1,郭艳玲1*,杨永振1,叶金1,纪文义2,刘宇轩1. 叠片式啮合圆弧齿轮排肥器设计与仿真试验[J]. 中国农业科技导报, 2020, 22(5): 78-85. |

| [9] | 康家鑫1,刘大为1,李旭1*,谢方平1,黄敏2,郑华斌2. 育秧泥浆处理装置曲柄滑块振动筛设计与参数优选[J]. 中国农业科技导报, 2020, 22(10): 85-92. |

| [10] | 唐春晓1,王兆瑞1,李恩邦1,2*. 桃核周围组织中光场分布特性的研究[J]. 中国农业科技导报, 2016, 18(4): 79-86. |

| [11] | 赵文举,马孝义,任洪艺,赵西安. 基于COM组件技术的渠系配水编组决策通用化软件研究[J]. , 2008, 10(4): 82-88. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||