中国农业科技导报 ›› 2022, Vol. 24 ›› Issue (7): 150-158.DOI: 10.13304/j.nykjdb.2021.0745

张家智( ), 王文玉, 王兴宇, 张常钰, 石书文, 何雨宣, 周红媛, 刘丽华, 郑桂萍(

), 王文玉, 王兴宇, 张常钰, 石书文, 何雨宣, 周红媛, 刘丽华, 郑桂萍( )

)

收稿日期:2021-07-08

接受日期:2021-10-20

出版日期:2022-07-15

发布日期:2022-08-15

通讯作者:

郑桂萍

作者简介:张家智 E-mail:781325632@qq.com;

基金资助:

Jiazhi ZHANG( ), Wenyu WANG, Xingyu WANG, Changyu ZHANG, Shuwen SHI, Yuxuan HE, Hongyuan ZHOU, Lihua LIU, Guiping ZHENG(

), Wenyu WANG, Xingyu WANG, Changyu ZHANG, Shuwen SHI, Yuxuan HE, Hongyuan ZHOU, Lihua LIU, Guiping ZHENG( )

)

Received:2021-07-08

Accepted:2021-10-20

Online:2022-07-15

Published:2022-08-15

Contact:

Guiping ZHENG

摘要:

为明确不同耕作模式下穴苗数对北方粳稻品质的影响,选用垦粳8号为材料,采用二因素裂区设计,研究耕作模式(A1:常规耕作;A2:垄作双深)和穴苗数(B1:3 苗·穴-1;B2:6 苗·穴-1;B3:9 苗·穴-1;B4:12 苗·穴-1)对稻米品质的影响。结果表明,垄作双深模式显著提高了稻米的加工品质和食味值;随着穴苗数增加,加工品质和外观品质均呈下降趋势,表现为B1>B2>B3>B4。其中,随着穴苗数增加,直链淀粉含量呈上升趋势;蛋白质含量呈下降趋势;而食味值先升高再降低,以B2处理最高,为82.46分,分别较B1、B3、B4处理提高1.47、0.20、0.15分。研究结果为垄作双深新模式的高产优质合理密植提供理论依据和技术支撑。

中图分类号:

张家智, 王文玉, 王兴宇, 张常钰, 石书文, 何雨宣, 周红媛, 刘丽华, 郑桂萍. 不同耕作模式下穴苗数对北方粳稻品质的影响[J]. 中国农业科技导报, 2022, 24(7): 150-158.

Jiazhi ZHANG, Wenyu WANG, Xingyu WANG, Changyu ZHANG, Shuwen SHI, Yuxuan HE, Hongyuan ZHOU, Lihua LIU, Guiping ZHENG. Effect of Hole Seedling Number on Quality of Northern Japonica Rice Under Different Cultivation Modes[J]. Journal of Agricultural Science and Technology, 2022, 24(7): 150-158.

耕作模式 Tillage pattern | 穴苗处理 Seedling treatment | 施肥位置 Fertilizer placement | 基肥 Base fertilizer | 分蘖肥 Tillering fertilizer | 调节肥 Regulating fertilizer | 穗肥 Panicle fertilizer | ||

|---|---|---|---|---|---|---|---|---|

| N | P2O5 | K2O | N | N | K2O | |||

| A1 | B1 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 |

| B2 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 | |

| B3 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 | |

| B4 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 | |

| A2 | B1 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

| B2 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 | |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

| B3 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 | |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

| B4 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 | |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

表1 不同处理的施肥种类及用量 (kg·hm-2)

Table 1 Fertilization type and amount in different treatments

耕作模式 Tillage pattern | 穴苗处理 Seedling treatment | 施肥位置 Fertilizer placement | 基肥 Base fertilizer | 分蘖肥 Tillering fertilizer | 调节肥 Regulating fertilizer | 穗肥 Panicle fertilizer | ||

|---|---|---|---|---|---|---|---|---|

| N | P2O5 | K2O | N | N | K2O | |||

| A1 | B1 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 |

| B2 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 | |

| B3 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 | |

| B4 | 全层Whole layers | 78.00 | 57.55 | 60.12 | 10.35 | 10.35 | 31.13 | |

| A2 | B1 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

| B2 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 | |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

| B3 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 | |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

| B4 | 上层Upper layer | 30.50 | 23.62 | 23.93 | 10.35 | 10.35 | 31.13 | |

| 下层Sublayer | 47.50 | 33.93 | 36.19 | — | — | — | ||

处理 Treatment | 糙米率 BRR/% | 精米率 PRR/% | 整精米率 HRR/% | |

|---|---|---|---|---|

| A1 | 82.03±0.71 bB | 71.25±0.60 bB | 60.78±0.71 bB | |

| A2 | 82.70±0.75 aA | 71.57±0.60 aA | 63.05±0.61 aA | |

| B1 | 83.28±0.32 aA | 72.20±0.31 aA | 62.77±1.26 aA | |

| B2 | 82.63±0.49 bB | 71.56±0.17 bB | 62.06±0.99 bB | |

| B3 | 82.10±0.58 cC | 71.12±0.29 cC | 61.58±1.33 cC | |

| B4 | 81.47±0.24 dD | 70.77±0.38 dC | 61.26±1.50 cC | |

F检验 F test | FA | 64.89** | 9.55** | 414.28** |

| FB | 86.29** | 36.58** | 34.85** | |

| FA×B | 2.51 | 0.33 | 2.56 | |

表2 不同处理的加工品质

Table 2 Processing quality of different treatments

处理 Treatment | 糙米率 BRR/% | 精米率 PRR/% | 整精米率 HRR/% | |

|---|---|---|---|---|

| A1 | 82.03±0.71 bB | 71.25±0.60 bB | 60.78±0.71 bB | |

| A2 | 82.70±0.75 aA | 71.57±0.60 aA | 63.05±0.61 aA | |

| B1 | 83.28±0.32 aA | 72.20±0.31 aA | 62.77±1.26 aA | |

| B2 | 82.63±0.49 bB | 71.56±0.17 bB | 62.06±0.99 bB | |

| B3 | 82.10±0.58 cC | 71.12±0.29 cC | 61.58±1.33 cC | |

| B4 | 81.47±0.24 dD | 70.77±0.38 dC | 61.26±1.50 cC | |

F检验 F test | FA | 64.89** | 9.55** | 414.28** |

| FB | 86.29** | 36.58** | 34.85** | |

| FA×B | 2.51 | 0.33 | 2.56 | |

处理 Treatment | 一次枝梗Primary branch | 二次枝梗Secondary branch | |||||||

|---|---|---|---|---|---|---|---|---|---|

谷粒长 Grain length/mm | 谷粒宽 Grain width/mm | 谷粒厚 Grain thickness/mm | 长宽比 Aspect ratio | 谷粒长 Grain length/mm | 谷粒宽 Grain width/mm | 谷粒厚 Grain thickness/mm | 长宽比 Aspect ratio | ||

| A1 | 6.933±0.15 aA | 3.280±0.11 aA | 2.265±0.07 aA | 2.115±0.04 aA | 6.643±0.17 aA | 3.214±0.9 aA | 2.236±0.07 aA | 2.068±0.05 aA | |

| A2 | 6.847±0.14 aA | 3.291±0.10 aA | 2.281±0.05 aA | 2.081±0.05 aA | 6.587±0.16 aA | 3.204±0.07 aA | 2.238±0.05 aA | 2.055±0.05 aA | |

| B1 | 7.038±0.19 aA | 3.370±0.07 aA | 2.330±0.06 aA | 2.090±0.04 aA | 6.653±0.24 aA | 3.267±0.10 aA | 2.273±0.08 aA | 2.037±0.04 aA | |

| B2 | 6.878±0.13 bAB | 3.272±0.11 abA | 2.273±0.06 bAB | 2.103±0.05 aA | 6.602±0.09 aA | 3.230±0.02 aAB | 2.252±0.03 aA | 2.045±0.02 aA | |

| B3 | 6.826±0.08 bB | 3.222±0.10 bA | 2.242±0.02 bB | 2.120±0.05 aA | 6.550±0.13 aA | 3.133±0.04 bB | 2.207±0.03 aA | 2.090±0.06 aA | |

| B4 | 6.815±0.07 bB | 3.278±0.08 abA | 2.248±0.03 bB | 2.078±0.05 aA | 6.655±0.18 aA | 3.207±0.07 abAB | 2.218±0.07 aA | 2.075±0.07 aA | |

F检验 F test | FA | 3.22 | 0.07 | 0.90 | 3.48 | 0.61 | 0.13 | 0.01 | 0.29 |

| FB | 4.63* | 2.24 | 6.44** | 0.96 | 0.47 | 4.07* | 2.20 | 1.02 | |

| FA×B | 1.62 | 0.91 | 4.62* | 0.47 | 0.98 | 0.98 | 2.32 | 0.11 | |

表3 不同处理的稻谷粒形

Table 3 Grain shape of different treatments

处理 Treatment | 一次枝梗Primary branch | 二次枝梗Secondary branch | |||||||

|---|---|---|---|---|---|---|---|---|---|

谷粒长 Grain length/mm | 谷粒宽 Grain width/mm | 谷粒厚 Grain thickness/mm | 长宽比 Aspect ratio | 谷粒长 Grain length/mm | 谷粒宽 Grain width/mm | 谷粒厚 Grain thickness/mm | 长宽比 Aspect ratio | ||

| A1 | 6.933±0.15 aA | 3.280±0.11 aA | 2.265±0.07 aA | 2.115±0.04 aA | 6.643±0.17 aA | 3.214±0.9 aA | 2.236±0.07 aA | 2.068±0.05 aA | |

| A2 | 6.847±0.14 aA | 3.291±0.10 aA | 2.281±0.05 aA | 2.081±0.05 aA | 6.587±0.16 aA | 3.204±0.07 aA | 2.238±0.05 aA | 2.055±0.05 aA | |

| B1 | 7.038±0.19 aA | 3.370±0.07 aA | 2.330±0.06 aA | 2.090±0.04 aA | 6.653±0.24 aA | 3.267±0.10 aA | 2.273±0.08 aA | 2.037±0.04 aA | |

| B2 | 6.878±0.13 bAB | 3.272±0.11 abA | 2.273±0.06 bAB | 2.103±0.05 aA | 6.602±0.09 aA | 3.230±0.02 aAB | 2.252±0.03 aA | 2.045±0.02 aA | |

| B3 | 6.826±0.08 bB | 3.222±0.10 bA | 2.242±0.02 bB | 2.120±0.05 aA | 6.550±0.13 aA | 3.133±0.04 bB | 2.207±0.03 aA | 2.090±0.06 aA | |

| B4 | 6.815±0.07 bB | 3.278±0.08 abA | 2.248±0.03 bB | 2.078±0.05 aA | 6.655±0.18 aA | 3.207±0.07 abAB | 2.218±0.07 aA | 2.075±0.07 aA | |

F检验 F test | FA | 3.22 | 0.07 | 0.90 | 3.48 | 0.61 | 0.13 | 0.01 | 0.29 |

| FB | 4.63* | 2.24 | 6.44** | 0.96 | 0.47 | 4.07* | 2.20 | 1.02 | |

| FA×B | 1.62 | 0.91 | 4.62* | 0.47 | 0.98 | 0.98 | 2.32 | 0.11 | |

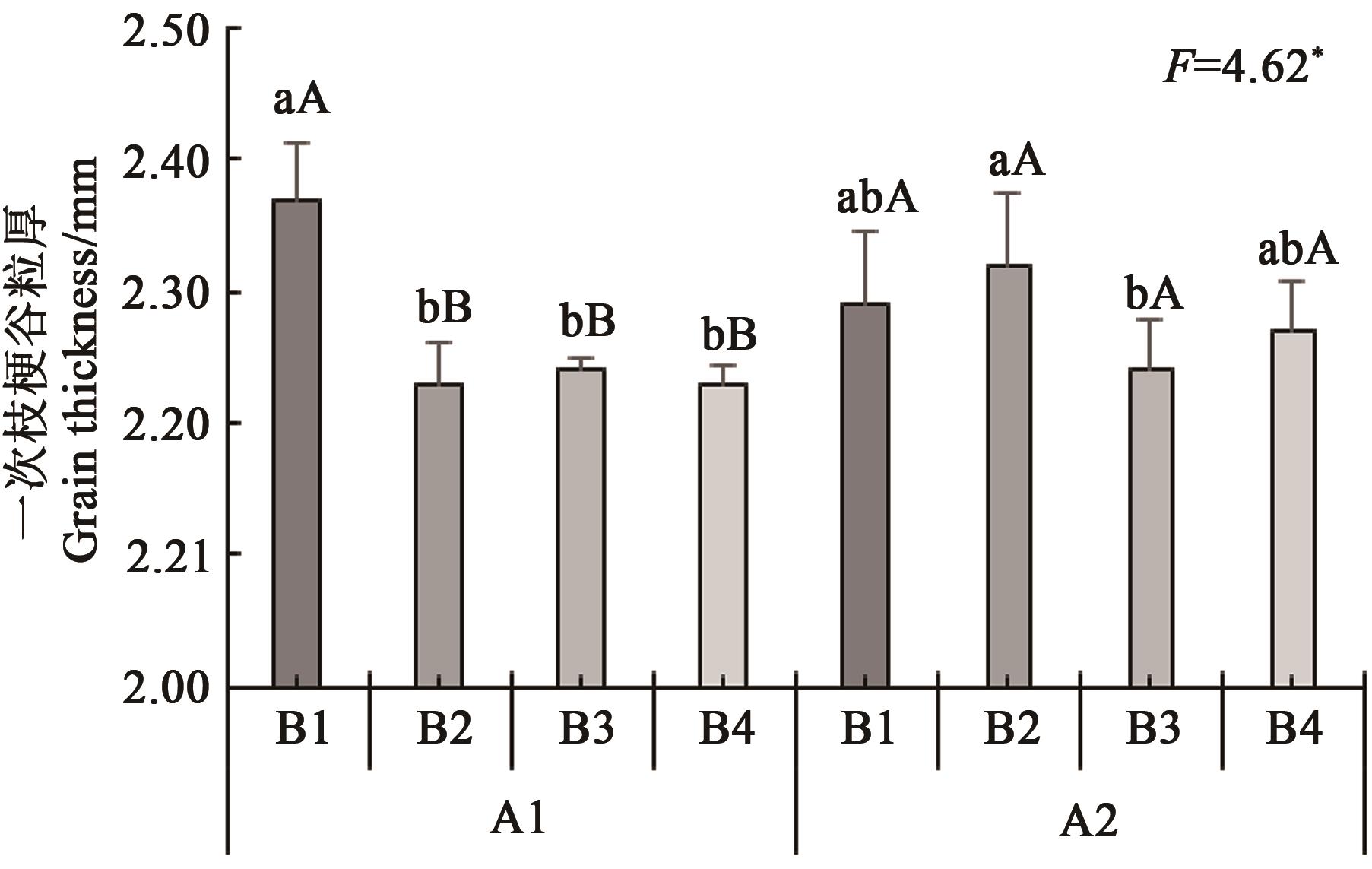

图2 不同处理一次枝梗谷粒的厚度注:不同小写字母表示不同处理间差异在P<0.05水平显著;不同大写字母表示不同处理间差异在P<0.01水平显著;*表示差异在P<0.05水平显著。

Fig. 2 Grain thickness of primary branch under different treatmentsNote: Different lowercase letters indicate significant differences between different treatments at P<0.05 level; different capital letters indicate significant differences between different treatments at P<0.01 level; *indicates significant difference at P<0.05 level.

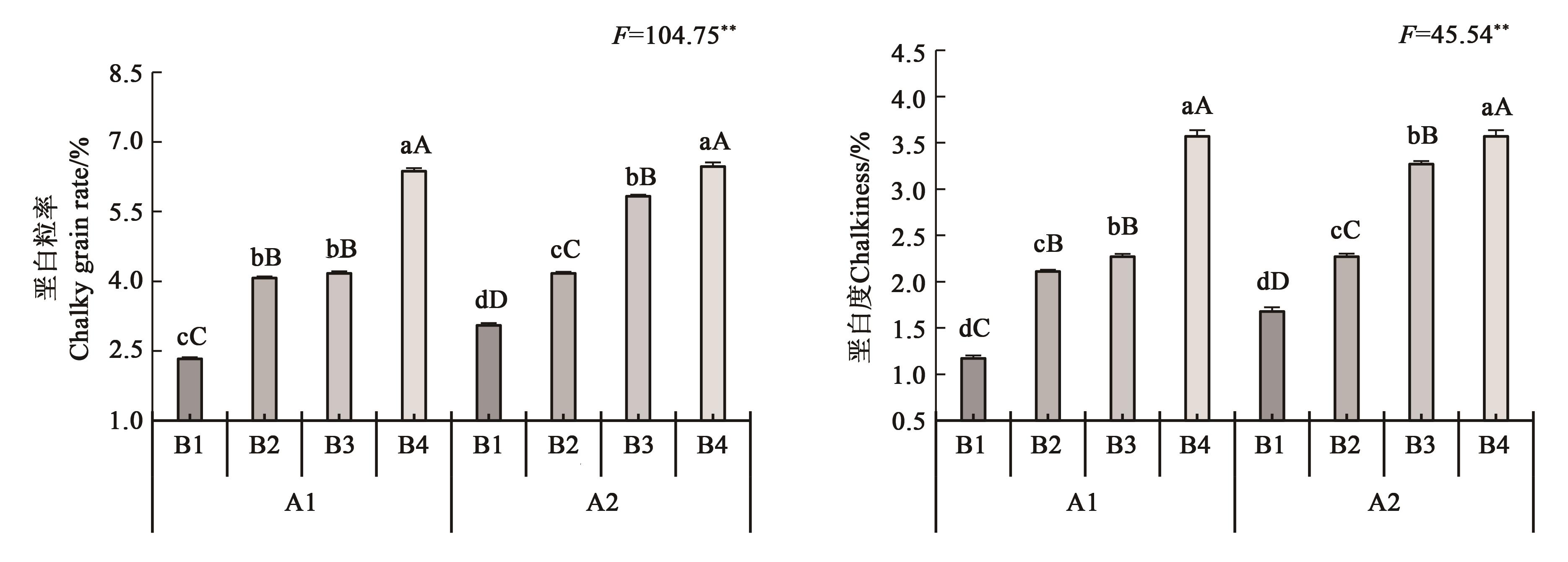

| 处理Treatment | 垩白粒率CGR/% | 垩白度Chalkiness/% | |

|---|---|---|---|

| A1 | 4.23±1.50 bB | 2.28±0.89 bB | |

| A2 | 4.88±1.41 aA | 2.70±0.79 aA | |

| B1 | 2.69±0.40 dD | 1.43±0.29 dD | |

| B2 | 4.12±0.07 cC | 2.19±0.09 cC | |

| B3 | 5.00±0.91 bB | 2.77±0.55 bB | |

| B4 | 6.42±0.13aA | 3.57±0.10 aA | |

F检验 F test | FA | 319.11** | 160.98** |

| FB | 1 868.78** | 760.61** | |

| FA×B | 104.75** | 45.54** | |

表4 不同处理的外观品质

Table 4 Appearance quality of different treatments

| 处理Treatment | 垩白粒率CGR/% | 垩白度Chalkiness/% | |

|---|---|---|---|

| A1 | 4.23±1.50 bB | 2.28±0.89 bB | |

| A2 | 4.88±1.41 aA | 2.70±0.79 aA | |

| B1 | 2.69±0.40 dD | 1.43±0.29 dD | |

| B2 | 4.12±0.07 cC | 2.19±0.09 cC | |

| B3 | 5.00±0.91 bB | 2.77±0.55 bB | |

| B4 | 6.42±0.13aA | 3.57±0.10 aA | |

F检验 F test | FA | 319.11** | 160.98** |

| FB | 1 868.78** | 760.61** | |

| FA×B | 104.75** | 45.54** | |

图3 不同处理的垩白粒率和垩白度注:不同小写字母表示不同处理间差异在P<0.05水平显著;不同大写字母表示不同处理间差异在P<0.01水平显著;**表示差异在P<0.05水平显著。

Fig. 3 Chalky grain percentage and chalkiness degree of different treatmentsNote: Different lowercase letters indicate significant differences between different treatments at P<0.05 level; different capital letters indicate significant differences between different treatments at P<0.01 level; ** indicates significant difference at P<0.05 level.

处理 Treatment | 直链淀粉含量 ASC/% | 蛋白质含量 RC/% | 水分含量 MC/% | |

|---|---|---|---|---|

| A1 | 15.87±0.33 aA | 7.93±0.14 aA | 16.15±0.38 aA | |

| A2 | 15.69±0.33 aA | 7.97±0.15 aA | 16.25±0.22 aA | |

| B1 | 15.49±0.28 cB | 8.09±0.06 aA | 15.85±0.32 cB | |

| B2 | 15.63±0.25 bcB | 8.01±0.13 aA | 16.48±0.12 aA | |

| B3 | 15.82±0.18 bAB | 7.87±0.09 bB | 16.29±0.22 abA | |

| B4 | 16.18±0.15 aA | 7.82±0.08 bB | 16.19±0.13 bA | |

F检验 F test | FA | 3.73 | 1.86 | 1.67 |

| FB | 10.70** | 16.49** | 11.40** | |

| FA×B | 0.51 | 4.27* | 2.68 | |

表5 营养品质的比较

Table 5 Comparison of nutritional quality

处理 Treatment | 直链淀粉含量 ASC/% | 蛋白质含量 RC/% | 水分含量 MC/% | |

|---|---|---|---|---|

| A1 | 15.87±0.33 aA | 7.93±0.14 aA | 16.15±0.38 aA | |

| A2 | 15.69±0.33 aA | 7.97±0.15 aA | 16.25±0.22 aA | |

| B1 | 15.49±0.28 cB | 8.09±0.06 aA | 15.85±0.32 cB | |

| B2 | 15.63±0.25 bcB | 8.01±0.13 aA | 16.48±0.12 aA | |

| B3 | 15.82±0.18 bAB | 7.87±0.09 bB | 16.29±0.22 abA | |

| B4 | 16.18±0.15 aA | 7.82±0.08 bB | 16.19±0.13 bA | |

F检验 F test | FA | 3.73 | 1.86 | 1.67 |

| FB | 10.70** | 16.49** | 11.40** | |

| FA×B | 0.51 | 4.27* | 2.68 | |

| 处理Treatment | 香气Fragrance | 完整性Integrity | 光泽luster | 味道Taste | 口感Mouthfeel | 食味值Taste value | |

|---|---|---|---|---|---|---|---|

| A1 | 7.70±0.06 aA | 7.14±0.09 bB | 8.24±0.29 aA | 8.32±0.11 aA | 8.03±0.29 aA | 81.90±1.99 aA | |

| A2 | 7.67±0.05 aA | 7.21±0.09 aA | 8.26±0.27 aA | 8.30±0.12 aA | 8.09±0.28 aA | 82.12±2.32 aA | |

| B1 | 7.67±0.08 aA | 7.21±0.12 aA | 8.16±0.30 aA | 8.25±0.14 bA | 7.98±0.28 aA | 80.99±2.33 aA | |

| B2 | 7.69±0.05 aA | 7.15±0.07 aA | 8.34±0.18 aA | 8.32±0.07 abA | 8.14±0.22 aA | 82.46±1.33 aA | |

| B3 | 7.70±0.05 aA | 7.15±0.08 aA | 8.31±0.28 aA | 8.34±0.11 aA | 8.06±0.35 aA | 82.26±2.32 aA | |

| B4 | 7.69±0.05 aA | 7.19±0.78 aA | 8.20±0.33 aA | 8.34±0.11 aA | 8.07±0.29 aA | 82.31±2.35 aA | |

F检验 F test | FA | 4.03 | 8.54** | 0.05 | 0.28 | 0.51 | 0.16 |

| FB | 0.68 | 1.62 | 1.18 | 2.16 | 0.68 | 1.50 | |

| FA×B | 0.89 | 2.24 | 0.82 | 1.90 | 1.47 | 2.54 | |

表6 食味值的比较

Table 6 Comparison of taste value

| 处理Treatment | 香气Fragrance | 完整性Integrity | 光泽luster | 味道Taste | 口感Mouthfeel | 食味值Taste value | |

|---|---|---|---|---|---|---|---|

| A1 | 7.70±0.06 aA | 7.14±0.09 bB | 8.24±0.29 aA | 8.32±0.11 aA | 8.03±0.29 aA | 81.90±1.99 aA | |

| A2 | 7.67±0.05 aA | 7.21±0.09 aA | 8.26±0.27 aA | 8.30±0.12 aA | 8.09±0.28 aA | 82.12±2.32 aA | |

| B1 | 7.67±0.08 aA | 7.21±0.12 aA | 8.16±0.30 aA | 8.25±0.14 bA | 7.98±0.28 aA | 80.99±2.33 aA | |

| B2 | 7.69±0.05 aA | 7.15±0.07 aA | 8.34±0.18 aA | 8.32±0.07 abA | 8.14±0.22 aA | 82.46±1.33 aA | |

| B3 | 7.70±0.05 aA | 7.15±0.08 aA | 8.31±0.28 aA | 8.34±0.11 aA | 8.06±0.35 aA | 82.26±2.32 aA | |

| B4 | 7.69±0.05 aA | 7.19±0.78 aA | 8.20±0.33 aA | 8.34±0.11 aA | 8.07±0.29 aA | 82.31±2.35 aA | |

F检验 F test | FA | 4.03 | 8.54** | 0.05 | 0.28 | 0.51 | 0.16 |

| FB | 0.68 | 1.62 | 1.18 | 2.16 | 0.68 | 1.50 | |

| FA×B | 0.89 | 2.24 | 0.82 | 1.90 | 1.47 | 2.54 | |

指标 Index | 糙米率 Brown rice rate | 精米率 Polished rice rate | 整精米率 Head rice rate | 直链淀粉含量 Amylose starch content | 蛋白质含量 Protein content | 水分含量Moisture content | 垩白粒率 Chalky grain rate | 垩白度 Chalkiness |

|---|---|---|---|---|---|---|---|---|

精米率 Polished rice rate | 0.95** | |||||||

整精米率 Head rice rate | 0.77* | 0.68* | ||||||

直链淀粉含量 Amylose starch content | -0.97** | -0.90** | -0.64 | |||||

蛋白质含量 Protein content | 0.94** | 0.92** | 0.63 | -0.90** | ||||

水分含量 Moisture content | -0.26 | -0.37 | -0.06 | 0.17 | -0.34 | |||

垩白粒率 Chalky grain rate | -0.72* | -0.84** | -0.21 | 0.79* | -0.77* | 0.42 | ||

垩白度 Chalkiness | -0.70* | -0.83** | -0.19 | 0.77* | -0.75* | 0.41 | 1.00** | |

食味值 Taste value | -0.29 | -0.41 | 0.06 | 0.22 | -0.48 | 0.83** | 0.49 | 0.47 |

表7 稻米品质性状间的相关分析

Table 7 Correlation analysis among quality traits of rice

指标 Index | 糙米率 Brown rice rate | 精米率 Polished rice rate | 整精米率 Head rice rate | 直链淀粉含量 Amylose starch content | 蛋白质含量 Protein content | 水分含量Moisture content | 垩白粒率 Chalky grain rate | 垩白度 Chalkiness |

|---|---|---|---|---|---|---|---|---|

精米率 Polished rice rate | 0.95** | |||||||

整精米率 Head rice rate | 0.77* | 0.68* | ||||||

直链淀粉含量 Amylose starch content | -0.97** | -0.90** | -0.64 | |||||

蛋白质含量 Protein content | 0.94** | 0.92** | 0.63 | -0.90** | ||||

水分含量 Moisture content | -0.26 | -0.37 | -0.06 | 0.17 | -0.34 | |||

垩白粒率 Chalky grain rate | -0.72* | -0.84** | -0.21 | 0.79* | -0.77* | 0.42 | ||

垩白度 Chalkiness | -0.70* | -0.83** | -0.19 | 0.77* | -0.75* | 0.41 | 1.00** | |

食味值 Taste value | -0.29 | -0.41 | 0.06 | 0.22 | -0.48 | 0.83** | 0.49 | 0.47 |

| 1 | 马盛群,王明海.不同肥源对稻米营养品质的影响[J].南京农专学报,2000(2):28-33. |

| MA S Q, WANG M H. Effects of different fertilizer sources on the nutritional quality of rice [J]. J. Nanjing Agric. Technol. Coll., 2000(2):28-33. | |

| 2 | 张欣悦,汪春,李连豪,等.水稻植质钵育秧盘制备工艺及参数优化[J].农业工程学报,2013,29(5):153-162. |

| ZHANG X Y, WANG C, LI L H, et al.. Preparation technology and parameter optimization of rice seedling trays with plant quality [J]. J. Agric. Eng., 2013, 29(5):153-162. | |

| 3 | 彭亚琼,郑华斌,扈婷,等.垄作梯式栽培对水稻根系生长的影响[J].作物研究,2012,26():14-17. |

| PENG Y Q, ZHENG H B, HU T, et al.. The effect of ridge cultivation and ladder cultivation on the growth of rice root system [J]. Crop Res., 2012, 26(S2):14-17. | |

| 4 | 李文淑,曾玉清,吕泽林,等.水稻垄作栽培增产效果及原因分析[J].农业科技通讯,2014(12):118-122. |

| LI W S, ZENG Y Q, LYU Z L, et al.. Yield-increasing effect and reason analysis of rice ridge cultivation [J]. Agric. Sci. Technol. Newslett., 2014(12):118-122. | |

| 5 | 莫惠栋.我国稻米品质的改良[J].中国农业科学,1993(4):8-14. |

| MO H D. Improvement of rice quality in my country [J]. Chin. Agric. Sci., 1993(4):8-14. | |

| 6 | 张自常,李鸿伟,陈婷婷,等.畦沟灌溉和干湿交替灌溉对水稻产量与品质的影响[J].中国农业科学,2011,44(24):4988-4998. |

| ZHANG Z C, LI H W, CHEN T T, et al.. The effect of border irrigation and alternate dry and wet irrigation on rice yield and quality [J]. China Agric. Sci., 2011, 44(24):4988-4998. | |

| 7 | 周晶.垄栽稻田养殖对水稻养分吸收及稻米营养品质的影响[D].长沙:湖南农业大学, 2019. |

| ZHOU J.The effect of ridged rice cultivation on rice nutrient absorption and rice nutritional quality [D]. Changsha: Hunan Agricultural University, 2019. | |

| 8 | 章秀福,王丹英,邵国胜.垄畦栽培水稻的产量、品质效应及其生理生态基础[J].中国水稻科学,2003(4):54-59. |

| ZHANG X F, WANG D Y, SHAO G S. Yield and quality effects of ridge and border cultivation of rice and its physiological and ecological basis [J]. China Rice Sci., 2003(4):54-59. | |

| 9 | 陈立强,赵海成,赫臣,等.氮肥运筹模式下垄作双深对水稻产量及品质的影响[J].河南农业科学,2018,47(7):20-26. |

| CHEN L Q, ZHAO H C, HE C, et al.. The effect of double-deep ridge cropping on rice yield and quality under nitrogen fertilizer management mode [J]. Henan Agric. Sci., 2018, 47(7):20-26. | |

| 10 | 薛亚光,魏亚凤,李波,等.麦秸还田和耕作方式对水稻产量和品质的影响[J].中国农学通报,2018,34(22):10-14. |

| XUE Y G, WEI Y F, LI B, et al.. The effect of returning wheat straw to the field and farming methods on rice yield and quality [J]. Chin. Agric. Sci. Bull., 2018, 34(22):10-14. | |

| 11 | 荆爱霞.移栽行距、密度对水稻超高产形成的影响[D].扬州:扬州大学,2008. |

| JING A X. The effect of transplanting row spacing and density on the formation of super-high yield of rice [D]. Jiangsu Yangzhou: Yangzhou University, 2008. | |

| 12 | 徐春梅,王丹英,邵国胜,等.施氮量和栽插密度对超高产水稻中早22产量和品质的影响[J].中国水稻科学,2008,22(5):507-512. |

| XU C M, WANG D Y, SHAO G S, et al.. Effects of nitrogen application rate and planting density on the yield and quality of super high-yield rice Zhongzao 22 [J]. China Rice Sci., 2008,22(5):507-512. | |

| 13 | 钱银飞,张洪程,李杰,等.不同基本苗配置对机插稻产量和品质的影响[J].华北农学报,2009,24():316-322. |

| QIAN Y F, ZHANG H C, LI J, et al.. The effect of different basic seedling configurations on the yield and quality of machine-transplanted rice [J]. J. North China Agric., 2009, 24(S1):316-322. | |

| 14 | 董啸波.密度对南方双季晚粳稻产量和群体质量及品质的影响[D]. 扬州:扬州大学,2013. |

| Dong X B. The effect of density on the yield and population quality and quality of southern double-cropping late japonica rice [D]. Yangzhou: Yangzhou University, 2013. | |

| 15 | 周培南,冯惟珠,许乃霞,等.施氮量和移栽密度对水稻产量及稻米品质的影响[J].江苏农业研究,2001(1):27-31. |

| ZHOU P N, FENG W Z, XU N X, et al.. Effects of nitrogen application rate and transplanting density on rice yield and rice quality [J]. Jiangsu Agric. Res., 2001(1): 27-31. | |

| 16 | 张自常,李鸿伟,陈婷婷,等.畦沟灌溉和干湿交替灌溉对水稻产量与品质的影响[J].中国农业科学,2011,44(24):4988-4998. |

| ZHANG Z C LI H W, CHEN T T, et al.. The effect of border irrigation and alternate dry and wet irrigation on rice yield and quality [J]. China Agric. Sci., 2011, 44(24):4988-4998. | |

| 17 | 程方民, 朱碧岩.气象生态因子对稻米品质影响的研究进展[J].中国农业气象, 1998,19(5) :39-45. |

| CHENG F M, ZHU B Y. Research progress on the influence of meteorological and ecological factors on rice quality [J]. Chin. Agric. Meteorol., 1998, 19(5):39-45. | |

| 18 | 冯明友.遗传与环境因素对水稻品质影响的研究进展[J].贵州农业科学,1996(1):56-59. |

| FENG M Y. Research progress on the influence of genetic and environmental factors on rice quality [J]. Guizhou Agric. Sci., 1996(1):56-59. |

| [1] | 陈小伟, 沙玉柱, 刘秀, 邵鹏阳, 王翻兄, 谢转回, 杨文鑫, 陈倩玲, 高敏, 黄薇. 不同物候期藏绵羊肉品质、营养成分及肉质相关基因表达特征分析[J]. 中国农业科技导报, 2025, 27(7): 161-171. |

| [2] | 宋光永, 郭雅文, 薛婧, 杨克箐, 苏学德, 周龙. 不同肥水处理对7个设施鲜食葡萄果实品质的影响[J]. 中国农业科技导报, 2025, 27(7): 229-240. |

| [3] | 朱燕芳, 常强, 郝燕, 陈海龙. 反光膜对‘阳光玫瑰’果实品质及挥发性物质的影响[J]. 中国农业科技导报, 2025, 27(7): 72-82. |

| [4] | 白世践, 户金鸽. 赤霉素处理对波尔莱特葡萄及葡萄干品质的影响[J]. 中国农业科技导报, 2025, 27(6): 158-169. |

| [5] | 黄娟娟, 张志强, 毛娟, 马宗桓, 陈佰鸿. 不同叶面肥对‘黑比诺’葡萄生长发育和果实品质的影响[J]. 中国农业科技导报, 2025, 27(6): 205-217. |

| [6] | 袁嘉良, 连润楠, 张吴平. 黄花菜花蕾的精准识别与分级方法[J]. 中国农业科技导报, 2025, 27(5): 103-112. |

| [7] | 张文婷, 李阳, 裘实, 路光明, 郭冬姝, 张保龙, 王金彦. 基于CRISPR/Cas9基因编辑技术研究Badh2基因对稻米品质的影响[J]. 中国农业科技导报, 2025, 27(5): 39-48. |

| [8] | 李大荣, 李小玲, 周武先, 张美德, 蒋小刚, 由金文, 王华. 有机肥替代部分化肥对湖北贝母生长及土壤性质的影响[J]. 中国农业科技导报, 2025, 27(3): 216-226. |

| [9] | 赵德轩, 高朋, 温晓蕾, 母时风, 高素红, 冯丽娜, 孙伟明, 齐慧霞. 板栗黄化皱缩病对板栗坚果品质的影响[J]. 中国农业科技导报, 2025, 27(2): 136-140. |

| [10] | 王如月, 虎海防, 罗莎莎, 甄紫怡, 徐业勇, 胡晓静. 杏李不同采收成熟度果实品质分析[J]. 中国农业科技导报, 2025, 27(2): 158-169. |

| [11] | 吴强, 吴聪连, 吴小云, 吴剑, 徐选美, 赖俊声, 胡伟云, 龚榜初, 江锡兵. 不同施肥处理对锥栗产量及果实品质的影响[J]. 中国农业科技导报, 2025, 27(2): 228-237. |

| [12] | 曾宝珍, 成永娟, 杨娟博, 车莉莉, 梁靖, 卢世雄, 梁国平, 马宗桓, 毛娟. 甘肃民勤地区‘慕合怀特’葡萄最佳采收期的确定[J]. 中国农业科技导报, 2025, 27(2): 70-79. |

| [13] | 王婷, 杜婧含, 张光弟, 王江龙, 贾毅男, 王玉, 包文毅. 宁南山区新优甘蓝品种品质及挥发性物质研究[J]. 中国农业科技导报, 2025, 27(1): 165-180. |

| [14] | 赵雅雯, 李绍稳. 农产品质量安全可信追溯体系构建与建议[J]. 中国农业科技导报, 2025, 27(1): 17-24. |

| [15] | 向兰婷, 宋曙辉, 刘立娟, 佘小玲, 周家华, 王宝刚, 常虹, 张超, 傅达奇, 王云香. 不同贮藏温度对京彩1号西瓜品质的影响[J]. 中国农业科技导报, 2024, 26(9): 137-145. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||