Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (11): 141-150.DOI: 10.13304/j.nykjdb.2024.0450

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Wenhui GUO( ), Feng LIU(

), Feng LIU( ), Wenliang LIU, Runjian DONG, Hansi ZHANG, Jian LI, Changyou WEI

), Wenliang LIU, Runjian DONG, Hansi ZHANG, Jian LI, Changyou WEI

Received:2024-06-05

Accepted:2024-09-24

Online:2025-11-15

Published:2025-11-17

Contact:

Feng LIU

国文慧( ), 刘枫(

), 刘枫( ), 刘文亮, 董润坚, 张含思, 李健, 魏常友

), 刘文亮, 董润坚, 张含思, 李健, 魏常友

通讯作者:

刘枫

作者简介:国文慧 E-mail:386260874@qq.com;

基金资助:CLC Number:

Wenhui GUO, Feng LIU, Wenliang LIU, Runjian DONG, Hansi ZHANG, Jian LI, Changyou WEI. Design and Testing of Key Components of Oil Salsa Bean Harvesting Equipment[J]. Journal of Agricultural Science and Technology, 2025, 27(11): 141-150.

国文慧, 刘枫, 刘文亮, 董润坚, 张含思, 李健, 魏常友. 油莎豆收获设备关键部件的设计与试验[J]. 中国农业科技导报, 2025, 27(11): 141-150.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2024.0450

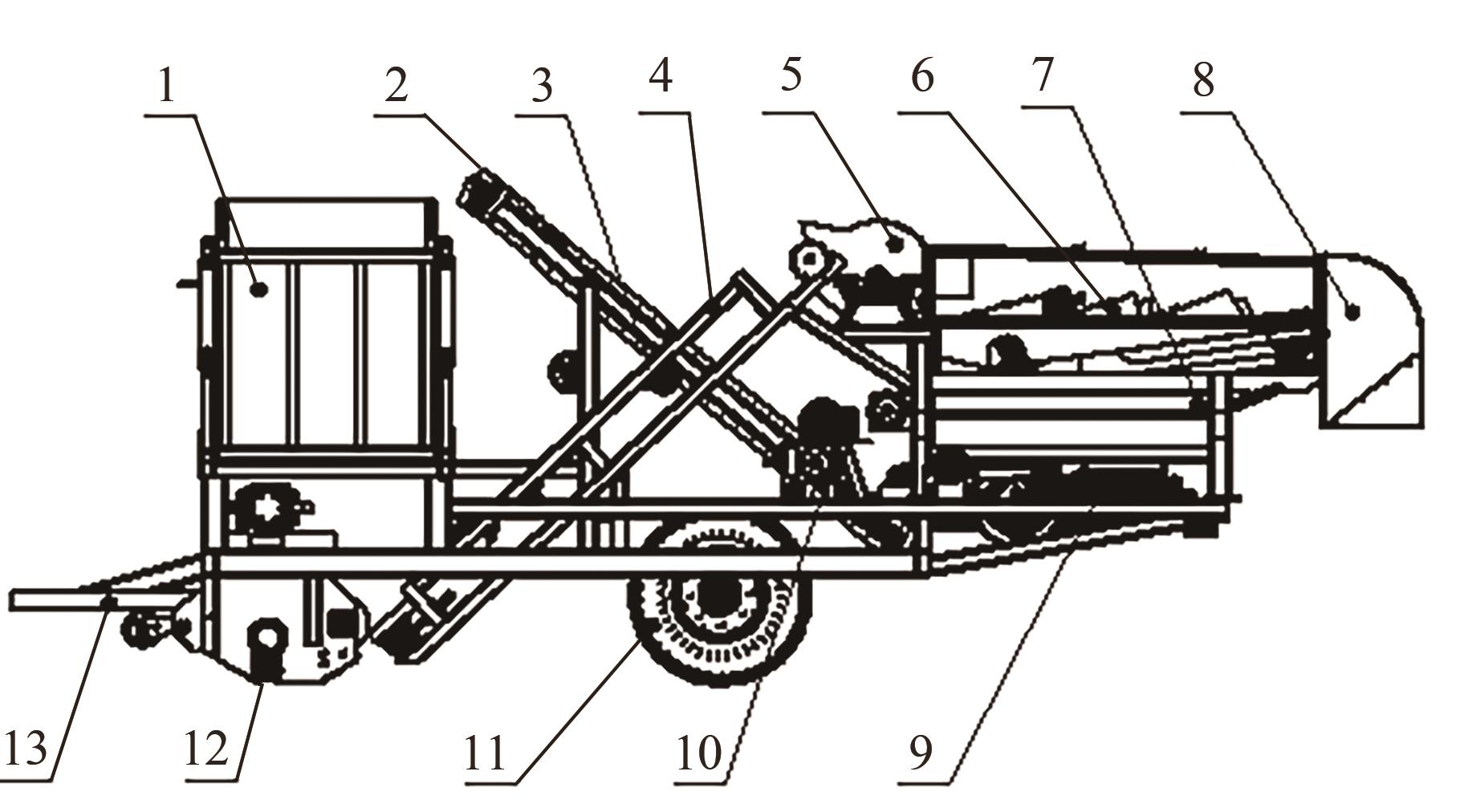

Fig. 1 Whole machine structure of oil salsa bean harvesterNote:1—Grain bin assembly; 2—Inclined belt loading device; 3—Vibrating axle pulley combination; 4—Inclined belt loading device; 5—Drum threshing device; 6—Draft sifter screening device; 7— Frames; 8—Baffles; 9—Horizontal chain conveyor; 10—Gearbox assembly; 11—Lightweight load-bearing tyres; 12—Dredging device; 13—Frame.

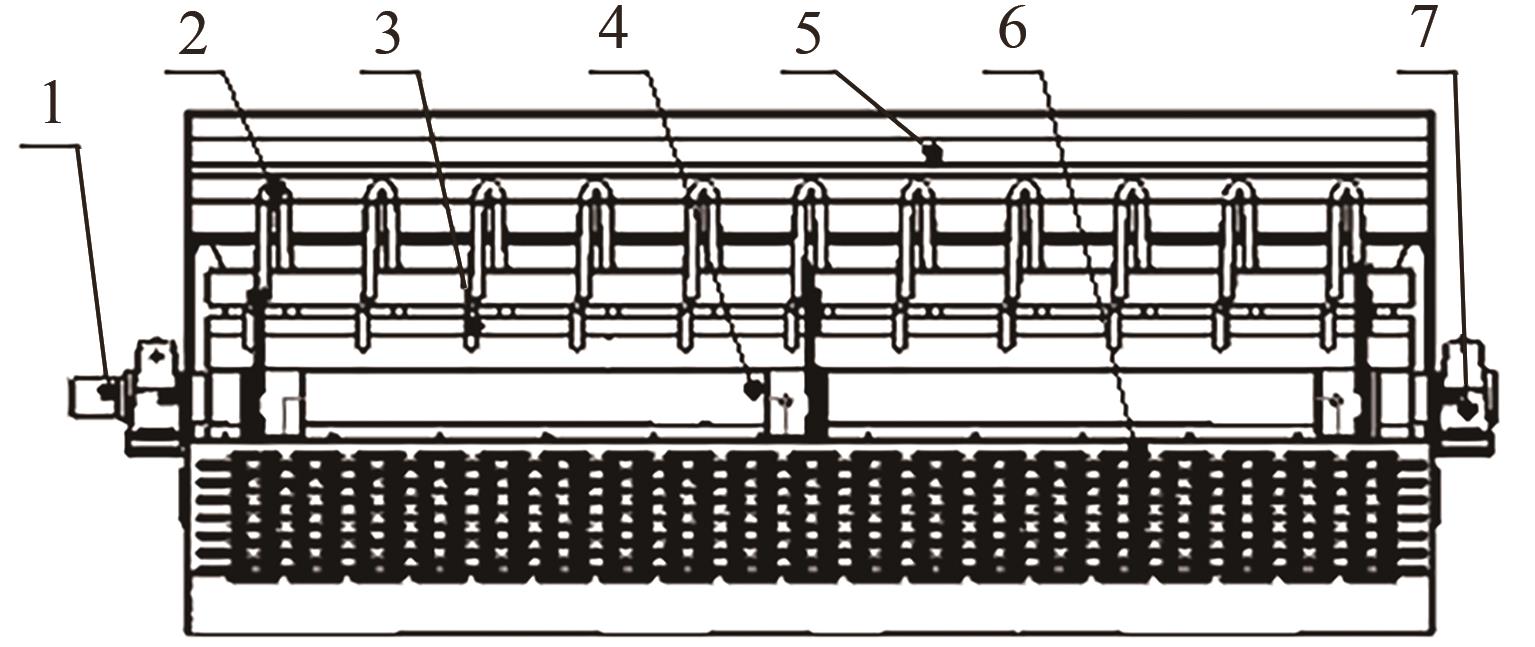

Fig. 3 Structure of conveyor chain deviceNote:1—Outer chain plate;2—Short inner chain plate;3—Roller;4—High inner chain plate;5—Pin;6—Long arm torsion springs;7—Short arm torsion springs;8—Hexagonal slotted nut.

| 水平 | 因素Factor | ||

|---|---|---|---|

A:网链线速度 Linear speed of mesh chain/(m·s-1) | B:网链角度 Angle of mesh chain/(°) | C:起振高度 Vibration height/mm | |

| -1 | 1.0 | 50 | 30 |

| 0 | 0.9 | 46 | 20 |

| 1 | 0.8 | 42 | 10 |

Table 1 Experimental factor level coding table

| 水平 | 因素Factor | ||

|---|---|---|---|

A:网链线速度 Linear speed of mesh chain/(m·s-1) | B:网链角度 Angle of mesh chain/(°) | C:起振高度 Vibration height/mm | |

| -1 | 1.0 | 50 | 30 |

| 0 | 0.9 | 46 | 20 |

| 1 | 0.8 | 42 | 10 |

Fig. 6 Components of drum threshing unitNote:1—Mandrel;2—Bow rule;3—Nail teeth;4—Shaft tube;5—Concave plate top cover;6—Concave plate sieve;7—Vertical seat bearing.

| 参数Parametric | 数值Value | 参数Parametric | 数值Value |

|---|---|---|---|

| 滚筒形式Roller form | 开式Open-ended | 齿排数 Number of rows of teeth | 11 |

滚筒直径 Roller diameter/mm | 420 | 齿数 Number of teeth | 66 |

滚筒长度 Roller length/mm | 1 300 | 齿高 Tooth height/mm | 70 |

喂入量 Feeding volume/(kg·s-1) | 8 | 齿距 Pitch/mm | 110 |

运转速度 Running speed/(r·min-1) | 295~386 | 螺旋头数 Number of spiral heads | 2 |

Table 2 Basic dimensional parameters of threshing drums

| 参数Parametric | 数值Value | 参数Parametric | 数值Value |

|---|---|---|---|

| 滚筒形式Roller form | 开式Open-ended | 齿排数 Number of rows of teeth | 11 |

滚筒直径 Roller diameter/mm | 420 | 齿数 Number of teeth | 66 |

滚筒长度 Roller length/mm | 1 300 | 齿高 Tooth height/mm | 70 |

喂入量 Feeding volume/(kg·s-1) | 8 | 齿距 Pitch/mm | 110 |

运转速度 Running speed/(r·min-1) | 295~386 | 螺旋头数 Number of spiral heads | 2 |

序号 Number | A:网链线速度 Linear speed of mesh chain/(m·s-1) | B:网链角度 Angle of mesh chain/(°) | C:起振高度 Vibration height/mm | 落土率 Rate of soil settlement/% | 漏豆率 Leakage rate/% |

|---|---|---|---|---|---|

| 1 | 0.8 | 50 | 20 | 63.12 | 0.57 |

| 2 | 0.9 | 56 | 10 | 60.00 | 0.52 |

| 3 | 0.8 | 46 | 10 | 52.14 | 0.46 |

| 4 | 0.9 | 50 | 20 | 70.40 | 0.56 |

| 5 | 0.8 | 46 | 60 | 69.90 | 0.62 |

| 6 | 0.8 | 42 | 20 | 60.80 | 0.53 |

| 7 | 0.9 | 12 | 10 | 53.00 | 0.45 |

| 8 | 1.0 | 46 | 10 | 68.81 | 0.59 |

| 9 | 1.0 | 46 | 30 | 70.33 | 0.59 |

| 10 | 0.9 | 50 | 10 | 58.22 | 0.53 |

| 11 | 1.0 | 50 | 20 | 70.34 | 0.56 |

| 12 | 0.9 | 46 | 20 | 69.53 | 0.55 |

| 13 | 0.9 | 46 | 20 | 69.71 | 0.55 |

| 14 | 0.9 | 50 | 30 | 72.12 | 0.56 |

| 15 | 0.9 | 46 | 30 | 71.24 | 0.55 |

| 16 | 1.0 | 42 | 20 | 60.23 | 0.62 |

| 17 | 0.9 | 42 | 30 | 65.81 | 0.58 |

Table 3 Experimental design options and results

序号 Number | A:网链线速度 Linear speed of mesh chain/(m·s-1) | B:网链角度 Angle of mesh chain/(°) | C:起振高度 Vibration height/mm | 落土率 Rate of soil settlement/% | 漏豆率 Leakage rate/% |

|---|---|---|---|---|---|

| 1 | 0.8 | 50 | 20 | 63.12 | 0.57 |

| 2 | 0.9 | 56 | 10 | 60.00 | 0.52 |

| 3 | 0.8 | 46 | 10 | 52.14 | 0.46 |

| 4 | 0.9 | 50 | 20 | 70.40 | 0.56 |

| 5 | 0.8 | 46 | 60 | 69.90 | 0.62 |

| 6 | 0.8 | 42 | 20 | 60.80 | 0.53 |

| 7 | 0.9 | 12 | 10 | 53.00 | 0.45 |

| 8 | 1.0 | 46 | 10 | 68.81 | 0.59 |

| 9 | 1.0 | 46 | 30 | 70.33 | 0.59 |

| 10 | 0.9 | 50 | 10 | 58.22 | 0.53 |

| 11 | 1.0 | 50 | 20 | 70.34 | 0.56 |

| 12 | 0.9 | 46 | 20 | 69.53 | 0.55 |

| 13 | 0.9 | 46 | 20 | 69.71 | 0.55 |

| 14 | 0.9 | 50 | 30 | 72.12 | 0.56 |

| 15 | 0.9 | 46 | 30 | 71.24 | 0.55 |

| 16 | 1.0 | 42 | 20 | 60.23 | 0.62 |

| 17 | 0.9 | 42 | 30 | 65.81 | 0.58 |

来源 Source | 平方和 Sum of squares | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 658.85 | 9 | 73.21 | 20.24 | 0.000 3** |

A:网链线速度 Linear speed of mesh chain | 73.09 | 1 | 73.09 | 20.21 | 0.002 8** |

B:网链角度 Angle of mesh chain | 13.73 | 1 | 13.73 | 3.80 | 0.092 4 |

C:起振高度 Vibration height | 168.38 | 1 | 168.38 | 46.55 | 0.000 2** |

| AB | 14.06 | 1 | 14.06 | 3.89 | 0.176 7 |

| AC | 66.42 | 1 | 66.42 | 18.36 | 0.003 6** |

| BC | 0.25 | 1 | 0.25 | 0.07 | 0.801 6 |

| A2 | 10.75 | 1 | 10.75 | 2.97 | 0.128 4 |

| B2 | 64.34 | 1 | 64.34 | 14.79 | 0.003 9** |

| C2 | 36.35 | 1 | 36.35 | 10.05 | 0.015 7* |

| 残差Residual | 25.32 | 7 | 3.62 | ||

| 失拟项Residual | 23.68 | 5 | 4.74 | 5.78 | 0.154 2 |

| 误差Error | 1.64 | 2 | 0.20 | ||

| 总和Total | 684.17 | 16 |

Table 4 Analysis of variance for soil fall rate

来源 Source | 平方和 Sum of squares | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 658.85 | 9 | 73.21 | 20.24 | 0.000 3** |

A:网链线速度 Linear speed of mesh chain | 73.09 | 1 | 73.09 | 20.21 | 0.002 8** |

B:网链角度 Angle of mesh chain | 13.73 | 1 | 13.73 | 3.80 | 0.092 4 |

C:起振高度 Vibration height | 168.38 | 1 | 168.38 | 46.55 | 0.000 2** |

| AB | 14.06 | 1 | 14.06 | 3.89 | 0.176 7 |

| AC | 66.42 | 1 | 66.42 | 18.36 | 0.003 6** |

| BC | 0.25 | 1 | 0.25 | 0.07 | 0.801 6 |

| A2 | 10.75 | 1 | 10.75 | 2.97 | 0.128 4 |

| B2 | 64.34 | 1 | 64.34 | 14.79 | 0.003 9** |

| C2 | 36.35 | 1 | 36.35 | 10.05 | 0.015 7* |

| 残差Residual | 25.32 | 7 | 3.62 | ||

| 失拟项Residual | 23.68 | 5 | 4.74 | 5.78 | 0.154 2 |

| 误差Error | 1.64 | 2 | 0.20 | ||

| 总和Total | 684.17 | 16 |

来源 Source | 平方和 Sumof square | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 0.033 | 9 | 3.653×10-3 | 16.82 | 0.000 6** |

A:网链线速度 Linear speed of mesh chain | 7.940×10-5 | 1 | 7.940×10-5 | 1.00 | 0.564 4 |

B:网链角度 Angle of mesh chain | 4.958×10-6 | 1 | 4.958×10-6 | 0.02 | 0.884 2 |

C:起振高度 Vibration height | 1.796×10-3 | 1 | 1.796×10-3 | 8.27 | 0.023 8 |

| AB | 2.280×10-3 | 1 | 2.280×10-3 | 10.50 | 0.014 2 |

| AC | 6.602×10-3 | 1 | 6.602×10-3 | 30.40 | 0.000 9** |

| BC | 3.102×10-3 | 1 | 3.102×10-3 | 14.25 | 0.006 9** |

| A2 | 3.015×10-3 | 1 | 3.015×10-3 | 13.89 | 0.007 4** |

| B2 | 2.615×10-5 | 1 | 2.615×10-5 | 0.15 | 0.738 8 |

| C2 | 9.977×10-4 | 1 | 9.977×10-4 | 4.50 | 0.071 6 |

| 残差Residual | 1.520×10-3 | 7 | 2.171×10-4 | ||

| 失拟项Lack of fit | 1.487×10-3 | 5 | 2.974×10-4 | 17.96 | 0.305 3 |

| 误差Error | 3.312×10-3 | 2 | 1.656×10-5 | ||

| 总和Total | 0.034 | 16 |

Table 5 Analysis of variance for bean leakage rate

来源 Source | 平方和 Sumof square | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 0.033 | 9 | 3.653×10-3 | 16.82 | 0.000 6** |

A:网链线速度 Linear speed of mesh chain | 7.940×10-5 | 1 | 7.940×10-5 | 1.00 | 0.564 4 |

B:网链角度 Angle of mesh chain | 4.958×10-6 | 1 | 4.958×10-6 | 0.02 | 0.884 2 |

C:起振高度 Vibration height | 1.796×10-3 | 1 | 1.796×10-3 | 8.27 | 0.023 8 |

| AB | 2.280×10-3 | 1 | 2.280×10-3 | 10.50 | 0.014 2 |

| AC | 6.602×10-3 | 1 | 6.602×10-3 | 30.40 | 0.000 9** |

| BC | 3.102×10-3 | 1 | 3.102×10-3 | 14.25 | 0.006 9** |

| A2 | 3.015×10-3 | 1 | 3.015×10-3 | 13.89 | 0.007 4** |

| B2 | 2.615×10-5 | 1 | 2.615×10-5 | 0.15 | 0.738 8 |

| C2 | 9.977×10-4 | 1 | 9.977×10-4 | 4.50 | 0.071 6 |

| 残差Residual | 1.520×10-3 | 7 | 2.171×10-4 | ||

| 失拟项Lack of fit | 1.487×10-3 | 5 | 2.974×10-4 | 17.96 | 0.305 3 |

| 误差Error | 3.312×10-3 | 2 | 1.656×10-5 | ||

| 总和Total | 0.034 | 16 |

序号 Number | 落土率 Rate of soil settlement/% | 漏豆率 Leakage rate/% |

|---|---|---|

| 1 | 66.96 | 0.57 |

| 2 | 67.02 | 0.54 |

| 3 | 66.53 | 0.54 |

| 平均值Average value | 66.83 | 0.55 |

Table 6 Repeat test results

序号 Number | 落土率 Rate of soil settlement/% | 漏豆率 Leakage rate/% |

|---|---|---|

| 1 | 66.96 | 0.57 |

| 2 | 67.02 | 0.54 |

| 3 | 66.53 | 0.54 |

| 平均值Average value | 66.83 | 0.55 |

项目 Sports event | 喂入量 Feeding volume/(kg·s-1) | 运转速度 Running speed/(r·min-1) | 破损率 Breakage rate/% | 脱净率 Decontamination rate/% |

|---|---|---|---|---|

全钉齿 Full complement of teeth | 8 | 340 | 1.12 | 99.12 |

| 1.13 | 99.10 | |||

| 1.06 | 99.32 | |||

| 1.12 | 99.20 | |||

| 1.16 | 99.14 | |||

平均值 Average value | 1.12 | 99.18 | ||

全弓齿 Full bow tooth | 8 | 340 | 1.32 | 99.16 |

| 1.25 | 99.13 | |||

| 1.28 | 99.23 | |||

| 1.28 | 99.12 | |||

| 1.24 | 99.26 | |||

平均值 Average value | 1.27 | 99.18 | ||

| 弓齿钉齿混合Mixed Aarch nail teeth | 8 | 340 | 1.14 | 99.52 |

| 1.12 | 99.33 | |||

| 1.15 | 99.21 | |||

| 1.02 | 99.26 | |||

| 1.07 | 99.35 | |||

平均值 Average value | 1.10 | 99.33 |

Table 7 Threshing drum test

项目 Sports event | 喂入量 Feeding volume/(kg·s-1) | 运转速度 Running speed/(r·min-1) | 破损率 Breakage rate/% | 脱净率 Decontamination rate/% |

|---|---|---|---|---|

全钉齿 Full complement of teeth | 8 | 340 | 1.12 | 99.12 |

| 1.13 | 99.10 | |||

| 1.06 | 99.32 | |||

| 1.12 | 99.20 | |||

| 1.16 | 99.14 | |||

平均值 Average value | 1.12 | 99.18 | ||

全弓齿 Full bow tooth | 8 | 340 | 1.32 | 99.16 |

| 1.25 | 99.13 | |||

| 1.28 | 99.23 | |||

| 1.28 | 99.12 | |||

| 1.24 | 99.26 | |||

平均值 Average value | 1.27 | 99.18 | ||

| 弓齿钉齿混合Mixed Aarch nail teeth | 8 | 340 | 1.14 | 99.52 |

| 1.12 | 99.33 | |||

| 1.15 | 99.21 | |||

| 1.02 | 99.26 | |||

| 1.07 | 99.35 | |||

平均值 Average value | 1.10 | 99.33 |

参数 Parameter | 区域Region | 平均值 Average value | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

测定区长度 Measuring zone length/m | 10 | 10 | 10 | 10 | 10 | 10 |

总质量 Total weight/kg | 470.43 | 460.85 | 470.32 | 480.5 | 470.68 | 470.55 |

收获油莎豆质量 Weight of harvested oleaginous beans/kg | 19.82 | 19.84 | 19.78 | 19.82 | 19.81 | 19.83 |

杂质和土壤质量 Weight of impurities and soil/kg | 450.50 | 440.91 | 450.41 | 460.56 | 450.73 | 450.60 |

漏豆质量 Weight of leakebeans/kg | 0.11 | 0.10 | 0.13 | 0.12 | 0.14 | 0.12 |

漏豆率 Leakage rate/% | 0.55 | 0.50 | 0.66 | 0.61 | 0.70 | 0.61 |

破损率 Breakage rate/% | 1.00 | 1.06 | 1.20 | 1.10 | 1.00 | 1.07 |

脱净率 Decontamination rate/% | 99.42 | 99.34 | 99.40 | 99.38 | 99.46 | 99.40 |

Table 8 Results of field trial

参数 Parameter | 区域Region | 平均值 Average value | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

测定区长度 Measuring zone length/m | 10 | 10 | 10 | 10 | 10 | 10 |

总质量 Total weight/kg | 470.43 | 460.85 | 470.32 | 480.5 | 470.68 | 470.55 |

收获油莎豆质量 Weight of harvested oleaginous beans/kg | 19.82 | 19.84 | 19.78 | 19.82 | 19.81 | 19.83 |

杂质和土壤质量 Weight of impurities and soil/kg | 450.50 | 440.91 | 450.41 | 460.56 | 450.73 | 450.60 |

漏豆质量 Weight of leakebeans/kg | 0.11 | 0.10 | 0.13 | 0.12 | 0.14 | 0.12 |

漏豆率 Leakage rate/% | 0.55 | 0.50 | 0.66 | 0.61 | 0.70 | 0.61 |

破损率 Breakage rate/% | 1.00 | 1.06 | 1.20 | 1.10 | 1.00 | 1.07 |

脱净率 Decontamination rate/% | 99.42 | 99.34 | 99.40 | 99.38 | 99.46 | 99.40 |

| [1] | 房芳, 敬思群, 马泽鑫, 等. 油莎豆蛋白营养评价[J].食品科技, 2013, 38(10): 69-73. |

| FANG F, JING S Q, MA Z X, et al.. Nutritional evaluation of oilsa bean protein [J]. Food Sci. Technol., 2013, 38(10): 69-73. | |

| [2] | 黄明华,王学华,庞震宇.油莎豆的研究现状及展望[J].作物研究, 2013, 27(3): 293-295, 301. |

| HUANG M H, WANG X H, PANG Z Y. Research status and prospect of Cyperus esculentus L. [J]. Crop Res., 2013,27(3):293-295, 301. | |

| [3] | 余珠, 邹智, 陆光远, 等. 油莎豆响应非生物胁迫的生理与分子机制研究进展[J/OL].分子植物育种, 2023: 1-7 [2024-05-06]. . |

| YU Z, ZOU Z, LU G Y, et al.. Progress in physiological and molecular mechanisms of oilseed bean in response to abiotic stress [J/OL]. Mol. Plant Breeding, 2023: 1-7 [2024-05-06]. . | |

| [4] | 赵清来, 陈晓明, 许顺,等. 油莎豆的应用价值及其播种和收获机的研究现状[J].农业技术与装备, 2022(1): 76-77, 80. |

| ZHAO Q L, CHEN X M, XU S, et al.. Application value of oilsa bean and current research status of its sowing and harvesting machine [J]. Agric. Technol. Equip., 2022 (1) :76-77, 80. | |

| [5] | 邸志峰,李青龙,姜伟,等.油莎豆种植与收获机械技术装备研究现状[J].山西农业大学学报(自然科学版),2022,42(2):96-106. |

| DI Z F, LI Q L, JIANG W, et al.. Research advance and perspective of Cyperus esculentus planting and harvesting machinery technology and equipment [J]. J. Shanxi Agric. Univ.(Nat. Sci.), 2022, 42(2): 96-106. | |

| [6] | 赵壮.油莎豆挖掘输送装置系统设计与试验研究[D].青岛:青岛农业大学, 2022. |

| ZHAO Z. System design and experimental study of digging conveyor device for oilsa bean [D]. Qingdao:Qingdao Agricultural University, 2022. | |

| [7] | 许永杰. 新型油莎豆收获机的设计与研究[D]. 北京:中国农业大学, 2016. |

| XU Y J. Design and research of a new oil salsa bean harvester [D]. Beijing: China Agricultural University, 2016. | |

| [8] | 刘文亮,孔令有,姜彩宇,等.油莎豆籽粒收获机的设计[J].农业开发与装备,2019(10):111-112. |

| [9] | 赵英琦,李兵杰,孟靓,等.油莎豆机械收获除杂系统优化设计[J].农机化研究,2022,44(8):51-56. |

| ZHAO Y Q, LI B J, MENG L, et al..Optimal design of mechanical harvesting and separation system for tiger nut [J]. J. Agric. Mech. Res., 2022, 44(8): 51-56. | |

| [10] | 季明仁.横轴流油莎豆脱粒装置的设计与试验研究[D].长春:吉林农业大学,2023. |

| JI M R. Design and experimental research on the threshing device of oil salsa bean with transverse axial flow [D]. Changchun: Jilin Agricultural University, 2023. | |

| [11] | 张胜伟, 张瑞雨, 曹庆秋, 等. 油莎豆收获机双层滚筒筛式分离装置设计与试验[J].农业机械学报, 2023, 54(3):148-157. |

| ZHANG S W, ZHANG R Y, CAO Q Q, et al.. Design and test of double-layer trommel screen-type separating device for oil salsa bean harvester [J]. J. Agric. Mach., 2023, 54(3):148-157. | |

| [12] | 王博涵.油莎豆收获机分离清选装置的试验研究[D].长春:吉林农业大学, 2022. |

| WANG B H. Experimental research on separation and cleaning device of oil salsa bean harvester [D]. Changchun: Jilin Agricultural University, 2022. | |

| [13] | 刘文亮,闫洪余,刘枫,等.复合筛分式油莎豆收获机设计及试验[J].农业工程,2023,13(2):88-94. |

| LIU W L, YAN H Y, LIU F, et al.. Design and experiment of compound screening Cyperus esculentus harvester [J]. Agric. Eng., 2023,13(2):88-94. | |

| [14] | 安世官.油莎豆脱粒分离装置的设计与试验[D].石河子:石河子大学,2022. |

| AN S G. Design and test of threshing and separating device for oil salsa bean [D]. Shihezi: Shihezi University, 2022. |

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号