Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (11): 131-140.DOI: 10.13304/j.nykjdb.2024.0398

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Long HUANG( ), Yulan LIAO(

), Yulan LIAO( ), Lin HUANG, Xiang PAN, Zhenpeng WU, Wenxiang ZHANG

), Lin HUANG, Xiang PAN, Zhenpeng WU, Wenxiang ZHANG

Received:2024-05-19

Accepted:2024-07-25

Online:2025-11-15

Published:2025-11-17

Contact:

Yulan LIAO

通讯作者:

廖宇兰

作者简介:黄龙 E-mail: hl948860482@163.com;

基金资助:CLC Number:

Long HUANG, Yulan LIAO, Lin HUANG, Xiang PAN, Zhenpeng WU, Wenxiang ZHANG. Design and Experiment of 4UMS-1000 Cassava Harvester[J]. Journal of Agricultural Science and Technology, 2025, 27(11): 131-140.

黄龙, 廖宇兰, 黄林, 潘翔, 吴振鹏, 张文翔. 4UMS-1000型木薯收获机的设计与试验[J]. 中国农业科技导报, 2025, 27(11): 131-140.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2024.0398

Fig. 1 4UMS-1000 cassava harvester machine structureNote: 1—Digging shovel with long and short feet; 2—Cassava tuber separation device; 3—Frame; 4—Reduction gear; 5—Three-stage vibrator; 6—Collection box; 7—Transmission system; 8—Supporting wheel;9—Walking wheel; 10—Depth limiting wheel.

技术参数 Technical parameter | 取值 Value |

|---|---|

外形尺寸(长×宽×高) Overall size (longth×width×height)/mm | 2 600×1 100×1 200 |

总质量 Total mass/kg | 470 |

配套动力 Auxiliary power/kW | 36.8 |

挖掘铲铲齿数目 Number of digging shovel teeth | 3 |

作业垄数 Number of ridges on a field | 1 |

机具前进速度 Harvester forward speed/(m·s-1) | 0.4~1.0 |

挖掘铲入土深度 Digging deep/mm | 150~200 |

薯土分离筛线速度 Speed of movement of cassava and soil separator screen/(m·s-1) | 0.6 |

工作幅宽 Working width/mm | 1 000 |

收集箱容积 Collection box volume/m3 | 0.8 |

Table 1 Main technical parameters of banana straw crushing and returning machine

技术参数 Technical parameter | 取值 Value |

|---|---|

外形尺寸(长×宽×高) Overall size (longth×width×height)/mm | 2 600×1 100×1 200 |

总质量 Total mass/kg | 470 |

配套动力 Auxiliary power/kW | 36.8 |

挖掘铲铲齿数目 Number of digging shovel teeth | 3 |

作业垄数 Number of ridges on a field | 1 |

机具前进速度 Harvester forward speed/(m·s-1) | 0.4~1.0 |

挖掘铲入土深度 Digging deep/mm | 150~200 |

薯土分离筛线速度 Speed of movement of cassava and soil separator screen/(m·s-1) | 0.6 |

工作幅宽 Working width/mm | 1 000 |

收集箱容积 Collection box volume/m3 | 0.8 |

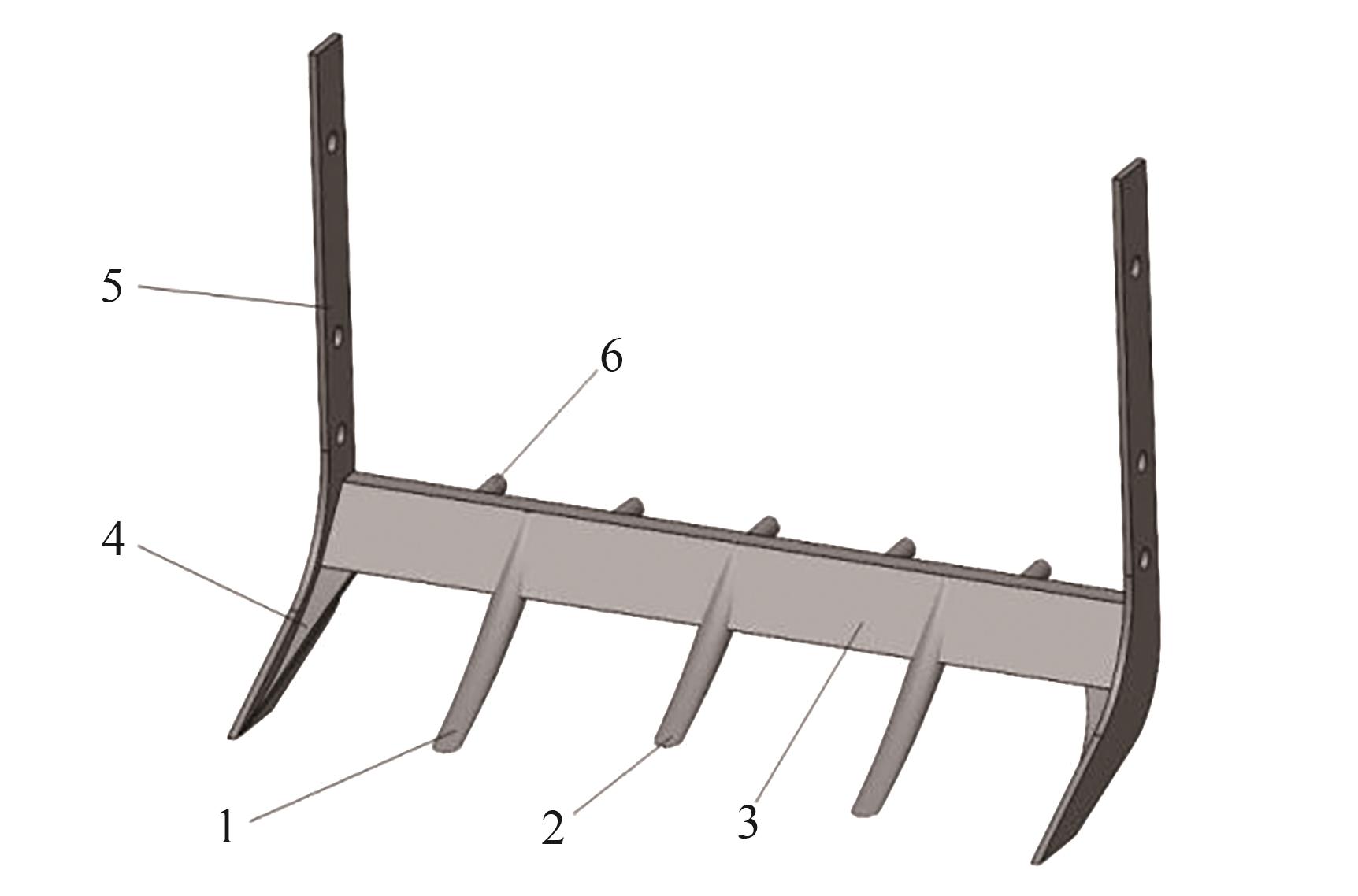

Fig. 2 Long and short foot excavation shovelsNote: 1—Long spade tooth; 2—Short spade teeth; 3—Shovel teeth beam; 4—Curved connecting side plate; 5—Mounting plate; 6—Guide bar.

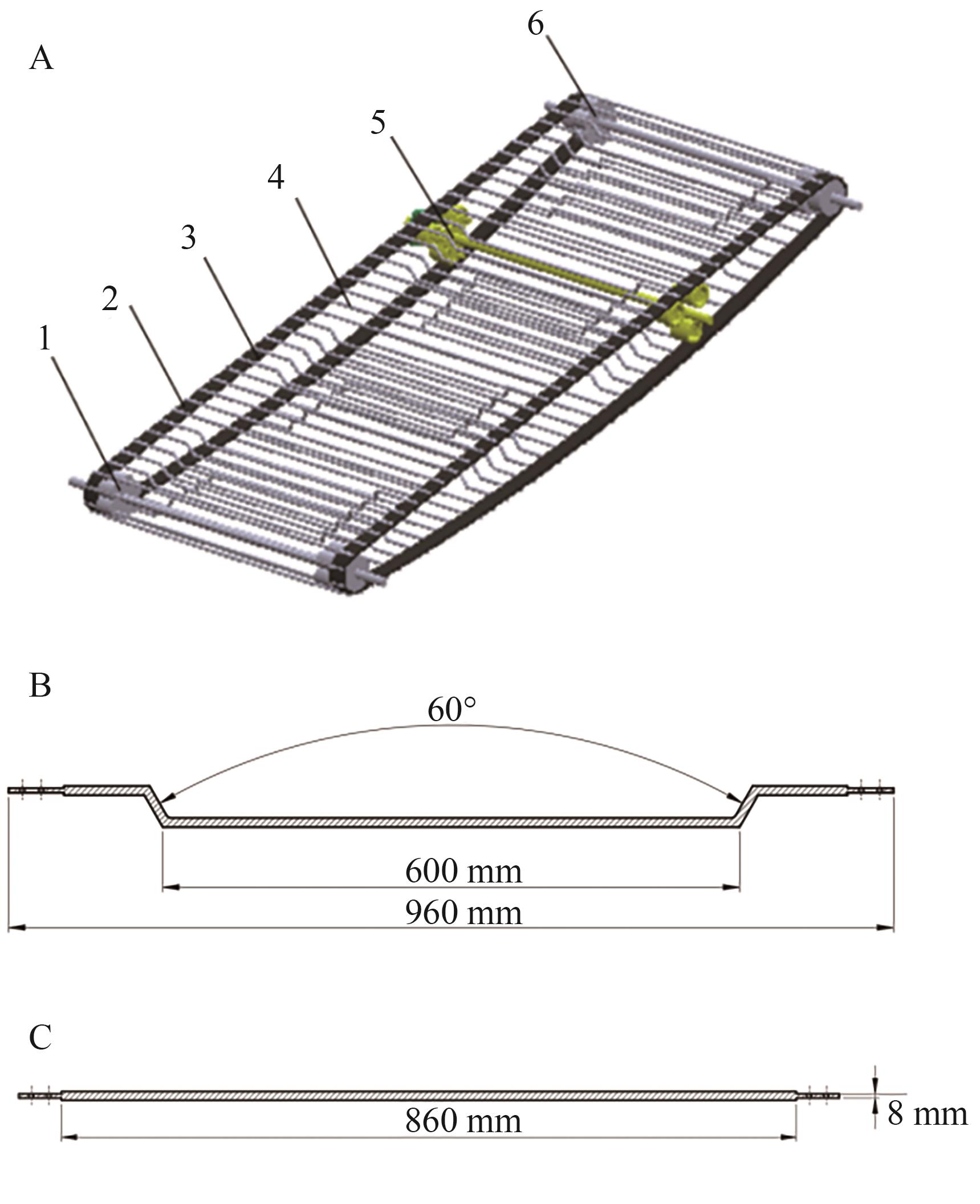

Fig. 5 Cassava soil separation unitA: Partial assembly diagram of cassava soil separator; B: Trapezoidal sieve bars; C: Ordinary sieve bars。1—Follower plum wheel; 2—Conveyor belt; 3—Ordinary screen bars; 4—Trapezoidal screen bars; 5—Vibrator; 6—Active plum wheel

水平 Level | 因素Factor | ||

|---|---|---|---|

Harvester forward speed/(m·s-1) | Shovel entry angle/(°) | Excavation shovel depth/mm | |

| -1 | 0.4 | 25 | 170 |

| 0 | 0.7 | 30 | 185 |

| 1 | 1.0 | 35 | 200 |

Table 2 Experimental factors and levels

水平 Level | 因素Factor | ||

|---|---|---|---|

Harvester forward speed/(m·s-1) | Shovel entry angle/(°) | Excavation shovel depth/mm | |

| -1 | 0.4 | 25 | 170 |

| 0 | 0.7 | 30 | 185 |

| 1 | 1.0 | 35 | 200 |

试验编号 Experimental number | Harvester forward speed/(m·s-1) | Shovel entry angle/(°) | Excavation shovel depth/mm | Cassava digging rate/% | Cassava injury rate/% |

|---|---|---|---|---|---|

| 1 | 0.4 | 25 | 185 | 94.46 | 3.29 |

| 2 | 1.0 | 25 | 185 | 85.21 | 6.58 |

| 3 | 0.4 | 35 | 185 | 97.56 | 6.58 |

| 4 | 1.0 | 35 | 185 | 90.21 | 8.09 |

| 5 | 0.4 | 30 | 170 | 91.71 | 4.99 |

| 6 | 1.0 | 30 | 170 | 91.31 | 8.95 |

| 7 | 0.4 | 30 | 200 | 96.62 | 7.12 |

| 8 | 1.0 | 30 | 200 | 83.56 | 6.18 |

| 9 | 0.7 | 25 | 170 | 87.21 | 5.62 |

| 10 | 0.7 | 35 | 170 | 96.42 | 7.64 |

| 11 | 0.7 | 25 | 200 | 92.56 | 3.99 |

| 12 | 0.7 | 35 | 200 | 93.31 | 7.01 |

| 13 | 0.7 | 30 | 185 | 96.27 | 4.11 |

| 14 | 0.7 | 30 | 185 | 97.19 | 3.83 |

| 15 | 0.7 | 30 | 185 | 96.82 | 3.78 |

| 16 | 0.7 | 30 | 185 | 97.58 | 3.91 |

| 17 | 0.7 | 30 | 185 | 95.51 | 3.52 |

Table 3 Experimental program and results

试验编号 Experimental number | Harvester forward speed/(m·s-1) | Shovel entry angle/(°) | Excavation shovel depth/mm | Cassava digging rate/% | Cassava injury rate/% |

|---|---|---|---|---|---|

| 1 | 0.4 | 25 | 185 | 94.46 | 3.29 |

| 2 | 1.0 | 25 | 185 | 85.21 | 6.58 |

| 3 | 0.4 | 35 | 185 | 97.56 | 6.58 |

| 4 | 1.0 | 35 | 185 | 90.21 | 8.09 |

| 5 | 0.4 | 30 | 170 | 91.71 | 4.99 |

| 6 | 1.0 | 30 | 170 | 91.31 | 8.95 |

| 7 | 0.4 | 30 | 200 | 96.62 | 7.12 |

| 8 | 1.0 | 30 | 200 | 83.56 | 6.18 |

| 9 | 0.7 | 25 | 170 | 87.21 | 5.62 |

| 10 | 0.7 | 35 | 170 | 96.42 | 7.64 |

| 11 | 0.7 | 25 | 200 | 92.56 | 3.99 |

| 12 | 0.7 | 35 | 200 | 93.31 | 7.01 |

| 13 | 0.7 | 30 | 185 | 96.27 | 4.11 |

| 14 | 0.7 | 30 | 185 | 97.19 | 3.83 |

| 15 | 0.7 | 30 | 185 | 96.82 | 3.78 |

| 16 | 0.7 | 30 | 185 | 97.58 | 3.91 |

| 17 | 0.7 | 30 | 185 | 95.51 | 3.52 |

试验指标 Experiment index | 方差来源 Source of variance | 平方和 Sum of squares | 自由度 Degree of freedom | 均方和 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

y1:明薯率 Cassava digging rate/% | 模型Model | 305.870 0 | 9 | 33.990 0 | 31.650 0 | <0.000 1** |

Harvester forward speed | 112.950 0 | 1 | 112.950 0 | 105.180 0 | <0.000 1** | |

Shovel entry angle | 40.770 0 | 1 | 40.770 0 | 37.970 0 | 0.000 5** | |

Excavation shovel depth | 0.045 0 | 1 | 0.045 0 | 0.041 9 | 0.843 6 | |

| 0.902 5 | 1 | 0.902 5 | 0.840 4 | 0.389 8 | ||

| 40.070 0 | 1 | 40.070 0 | 37.310 0 | 0.000 5** | ||

| 17.890 0 | 1 | 17.890 0 | 16.660 0 | 0.004 7** | ||

| 42.970 0 | 1 | 42.970 0 | 40.010 0 | 0.000 4** | ||

| 11.040 0 | 1 | 11.040 0 | 10.280 0 | 0.014 9** | ||

| 30.230 0 | 1 | 30.230 0 | 28.150 0 | 0.001 1** | ||

| 残差Residual | 7.520 0 | 7 | 1.070 0 | |||

| 失拟项Lack of fit | 4.890 0 | 3 | 1.630 0 | 2.480 0 | 0.200 2 | |

| 纯误差Pure error | 2.630 0 | 4 | 0.656 6 | |||

| 总和Cor total | 313.390 0 | 16 | ||||

y2:伤薯率 Cassava injury rate/% | 模型Model | 51.370 0 | 9 | 5.710 0 | 43.680 0 | <0.000 1** |

Harvester forward speed | 7.640 0 | 1 | 7.640 0 | 58.500 0 | 0.000 1** | |

Shovel entry angle | 12.100 0 | 1 | 12.100 0 | 92.620 0 | <0.000 1** | |

Excavation shovel depth | 1.050 0 | 1 | 1.050 0 | 8.040 0 | 0.025 2* | |

| 0.792 1 | 1 | 0.792 1 | 6.060 0 | 0.043 3* | ||

| 6.000 0 | 1 | 6.000 0 | 45.940 0 | 0.000 3** | ||

| 0.250 0 | 1 | 0.250 0 | 1.910 0 | 0.209 1 | ||

| 9.790 0 | 1 | 9.790 0 | 74.940 0 | <0.000 1** | ||

| 2.560 0 | 1 | 2.560 0 | 19.600 0 | 0.003 1** | ||

| 8.910 0 | 1 | 8.910 0 | 68.220 0 | <0.000 1** | ||

| 残差Residual | 0.914 7 | 7 | 0.130 7 | |||

| 失拟项Lack of fit | 0.731 3 | 3 | 0.243 8 | 5.320 0 | 0.070 1 | |

| 纯误差Pure error | 0.183 4 | 4 | 0.045 9 | |||

| 总和Cor total | 52.290 0 | 16 |

Table 4 Analysis of variance for cassava digging rate, cassava injuring rate

试验指标 Experiment index | 方差来源 Source of variance | 平方和 Sum of squares | 自由度 Degree of freedom | 均方和 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

y1:明薯率 Cassava digging rate/% | 模型Model | 305.870 0 | 9 | 33.990 0 | 31.650 0 | <0.000 1** |

Harvester forward speed | 112.950 0 | 1 | 112.950 0 | 105.180 0 | <0.000 1** | |

Shovel entry angle | 40.770 0 | 1 | 40.770 0 | 37.970 0 | 0.000 5** | |

Excavation shovel depth | 0.045 0 | 1 | 0.045 0 | 0.041 9 | 0.843 6 | |

| 0.902 5 | 1 | 0.902 5 | 0.840 4 | 0.389 8 | ||

| 40.070 0 | 1 | 40.070 0 | 37.310 0 | 0.000 5** | ||

| 17.890 0 | 1 | 17.890 0 | 16.660 0 | 0.004 7** | ||

| 42.970 0 | 1 | 42.970 0 | 40.010 0 | 0.000 4** | ||

| 11.040 0 | 1 | 11.040 0 | 10.280 0 | 0.014 9** | ||

| 30.230 0 | 1 | 30.230 0 | 28.150 0 | 0.001 1** | ||

| 残差Residual | 7.520 0 | 7 | 1.070 0 | |||

| 失拟项Lack of fit | 4.890 0 | 3 | 1.630 0 | 2.480 0 | 0.200 2 | |

| 纯误差Pure error | 2.630 0 | 4 | 0.656 6 | |||

| 总和Cor total | 313.390 0 | 16 | ||||

y2:伤薯率 Cassava injury rate/% | 模型Model | 51.370 0 | 9 | 5.710 0 | 43.680 0 | <0.000 1** |

Harvester forward speed | 7.640 0 | 1 | 7.640 0 | 58.500 0 | 0.000 1** | |

Shovel entry angle | 12.100 0 | 1 | 12.100 0 | 92.620 0 | <0.000 1** | |

Excavation shovel depth | 1.050 0 | 1 | 1.050 0 | 8.040 0 | 0.025 2* | |

| 0.792 1 | 1 | 0.792 1 | 6.060 0 | 0.043 3* | ||

| 6.000 0 | 1 | 6.000 0 | 45.940 0 | 0.000 3** | ||

| 0.250 0 | 1 | 0.250 0 | 1.910 0 | 0.209 1 | ||

| 9.790 0 | 1 | 9.790 0 | 74.940 0 | <0.000 1** | ||

| 2.560 0 | 1 | 2.560 0 | 19.600 0 | 0.003 1** | ||

| 8.910 0 | 1 | 8.910 0 | 68.220 0 | <0.000 1** | ||

| 残差Residual | 0.914 7 | 7 | 0.130 7 | |||

| 失拟项Lack of fit | 0.731 3 | 3 | 0.243 8 | 5.320 0 | 0.070 1 | |

| 纯误差Pure error | 0.183 4 | 4 | 0.045 9 | |||

| 总和Cor total | 52.290 0 | 16 |

试验号 Experiment number | 机具前进速度Harvester forward speed/(m·s-1) | 挖掘铲入土角 Shovel entry angle/(°) | 挖掘铲入土深度 Excavation shovel depth/mm | 明薯率Cassava digging rate/% | 伤薯率 Cassava injury rate/% |

|---|---|---|---|---|---|

| 1 | 0.56 | 28 | 187 | 96.38 | 4.78 |

| 2 | 95.21 | 4.32 | |||

| 3 | 94.32 | 5.35 | |||

| 4 | 95.75 | 4.46 | |||

| 5 | 93.32 | 4.12 |

Table 5 Analysis of validation results

试验号 Experiment number | 机具前进速度Harvester forward speed/(m·s-1) | 挖掘铲入土角 Shovel entry angle/(°) | 挖掘铲入土深度 Excavation shovel depth/mm | 明薯率Cassava digging rate/% | 伤薯率 Cassava injury rate/% |

|---|---|---|---|---|---|

| 1 | 0.56 | 28 | 187 | 96.38 | 4.78 |

| 2 | 95.21 | 4.32 | |||

| 3 | 94.32 | 5.35 | |||

| 4 | 95.75 | 4.46 | |||

| 5 | 93.32 | 4.12 |

| [1] | 邵鹏程, 赵峰, 张男吉, 等. 木薯渣饲料的营养特性及其在畜禽养殖中的应用研究进展[J]. 中国畜牧杂志, 2023, 59(10): 36-41. |

| SHAO P C, ZHAO F, ZHANG N J, et al.. Research progress on nutritional characteristics of cassava residue and its application in livestock and poultry production [J]. Chin. J. Anim. Sci., 2023, 59(10): 36-41. | |

| [2] | 魏艳, 黄洁, 林立铭, 等. 木薯块根不同部位的营养成分研究[J]. 西北农林科技大学学报(自然科学版), 2016, 44(6): 53-61. |

| WEI Y, HUANG J, LIN L M, et al.. Nutrients in different parts of cassava root [J]. J. Northwest A&F Univ. (Nat. Sci.), 2016, 44(6): 53-61. | |

| [3] | 谭砚文, 李丛希, 曾华盛. 中国木薯生产和贸易发展分析[J]. 世界农业, 2018(10): 163-168. |

| [4] | BECHOFFA, TOMLINS K, FLIEDELG, et al.. Cassava traits and enduser preference: relating traits to consumer liking, sensory perception, and genetics [J]. Crit. Rev. Food Sci. Nutr., 2018, 58(4): 547-567. |

| [5] | 杨怡, 廖宇兰, 郑侃, 等. 木薯田间机械化作业研究现状分析[J]. 广东农业科学, 2015, 42(8): 137-140. |

| YANG Y, LIAO Y L, ZHENG K, et al.. Present situation analysis of cassava field mechanization [J]. Guangdong Agric. Sci., 2015, 42(8): 137-140. | |

| [6] | 张意松, 黄晖, 崔振德. 国内木薯收获机采挖原理和结构设计[J]. 热带农业工程, 2012, 36(5): 17-20. |

| ZHANG Y S, HUANG H, CUI Z D. Harvesting principle and structure design of cassava harvester [J]. Trop. Agric. Eng., 2012, 36(5): 17-20. | |

| [7] | 覃双眉, 李明. 国内外木薯种植机械研究进展[J]. 安徽农业科学, 2011, 39(8): 5016-5018. |

| QIN S M, LI M. Review on the development of cassava planting machinery at home and abroad [J]. J. Anhui Agric. Sci., 2011, 39(8): 5016-5018. | |

| [8] | 曾永联, 张华勇. 广西武鸣成功研制木薯收获机[J]. 世界热带农业信息, 2009(3): 24. |

| [9] | 王涛, 廖宇兰, 刘世豪, 等. 挖拔式木薯联合收获机的设计[J]. 农机化研究, 2016, 38(6): 126-131. |

| WANG T, LIAO Y L, LIU S H, et al.. Design and research of digging pull cassava combine harvester [J]. J. Agric. Mech. Res., 2016, 38(6): 126-131. | |

| [10] | 李玲, 黄应强, 邓干然, 等. 4UMS-1800型木薯起薯收获机提升装置的设计[J]. 农机化研究, 2018, 40(9): 149-153. |

| LI L, HUANG Y Q, DENG G R, et al.. The design of lifting device for 4UMS-1800 cassava harvesting machine [J]. J. Agric. Mech. Res., 2018, 40(9): 149-153. | |

| [11] | 李国杰, 邓干然, 吴洪珠, 等. 4UMZ-1400型后收集式木薯联合收获机设计与试验[J]. 中国农机化学报, 2022, 43(03): 1-8. |

| LI G J, DENG G R, WU H Z, et al.. Design and experiment of 4UMZ-1400 rear-collected type cassava combined harvester [J]. J. Chin. Agric. Mechan., 2022, 43(3): 1-8. | |

| [12] | 王之东, 周军平, 杨学军, 等. 木薯块根收获技术与机具研究进展[J]. 农业工程, 2019, 9(1): 1-8. |

| WANG Z D, ZHOU J P, YANG X J, et al.. Research progress of cassava tuber harvesting technology and machine [J]. Agric. Eng., 2019, 9(1): 1-8. | |

| [13] | YANG W, LI J, YANG J, et al.. Numerical simulation of an experienced farmer lifting tubers of cassava for designing a bionic harvester [J]. CMES: Comp. Model. Eng. Sci., 2015, 104: 471-491. |

| [14] | 李国杰, 邓干然, 吴洪珠, 等. 4UML-130型振动链式木薯收获机的设计与试验[J]. 现代农业装备, 2022, 43(1): 24-29, 54. |

| LI G J, DENG G R, WU H Z, et al.. Analysis of mechanical damage in cassava harvesting [J]. Mod. Agric. Equip., 2022, 43(1): 24-29, 54. | |

| [15] | 益爱丽, 廖宇兰, 吕凯英, 等. 一种木薯收获机仿生挖掘铲的设计方法[J]. 农机化研究, 2018, 40(10): 63-68. |

| YI A L, LIAO Y L, LYU K Y, et al.. The design of bionic digging shovel for cassava harvesting [J]. J. Agric. Mech. Res., 2018, 40(10): 63-68. | |

| [16] | 吴家安, 李向军, 高明宇, 等. 板蓝根收获机挖掘装置设计与有限元分析[J]. 中国农机化学报, 2023, 44(9): 16-21. |

| WU J A, LI X J, GAO M Y, et al.. Design and finite element analysis of mining device of Radix isatidis root harvester [J]. J. Chin. Agric. Mech., 2023, 44(9): 16-21. | |

| [17] | ITO M, SAKAI K, HATA S, et al.. Technical notes: damage to the surface of cassvaes from collision [J]. Trans. ASAE, 1994, 37(5): 1431-1433. |

| [18] | AMPONSAH S, BOBOBEE E, AGYARE W A, et al.. Mechanical cassava harvesting as influenced by seedbed preparation and cassava variety [J]. Appl. Eng. Agric., 2014, 30(3): 391-403. |

| [19] | 王海军, 周风林, 王强, 等. 马铃薯收获机 质量评价技术规范: [S]. 北京: 中国农业出版社, 2015. |

| [20] | 吕以志, 黄应强, 李晓菲, 等. 振动链式木薯挖掘收获机的性能试验与分析[J]. 现代农业装备, 2017(5): 39-42. |

| LYU Y Z, HUANG Y Q, LI X F, et al.. Performance test and analysis of the vibrating-chain cassava excavating harvester [J]. Mod. Agric. Equip., 2017(5): 39-42. |

| [1] | HUANG Yu, FAN Qizhou*, WANG Lie, FAN Xianhong. Design of Biomass Carbonization Equipment for Vertical Moving Bed [J]. Journal of Agricultural Science and Technology, 2018, 20(11): 69-78. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号