Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (11): 90-102.DOI: 10.13304/j.nykjdb.2022.0237

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Fake SHAN1( ), Shuo KANG1, Jianxi ZHU2, Yongwei WANG1, Jun WANG1(

), Shuo KANG1, Jianxi ZHU2, Yongwei WANG1, Jun WANG1( )

)

Received:2022-03-28

Accepted:2022-06-06

Online:2023-11-15

Published:2023-11-20

Contact:

Jun WANG

单发科1( ), 康朔1, 朱建锡2, 王永维1, 王俊1(

), 康朔1, 朱建锡2, 王永维1, 王俊1( )

)

通讯作者:

王俊

作者简介:单发科 E-mail: 21913001@zju.edu.cn;

基金资助:CLC Number:

Fake SHAN, Shuo KANG, Jianxi ZHU, Yongwei WANG, Jun WANG. Study on Tillage Fertilizer Mixing Effect Under Vertical Smashing Rotary Tillage and Rotary Tillage Based on EDEM[J]. Journal of Agricultural Science and Technology, 2023, 25(11): 90-102.

单发科, 康朔, 朱建锡, 王永维, 王俊. 基于EDEM的粉垄和旋耕作业混肥效果研究[J]. 中国农业科技导报, 2023, 25(11): 90-102.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2022.0237

| 耕作方式 Tillage method | 耕作幅宽 Tillage width/m | 最大耕深 Tillage depth/cm | l a d e s p e e d /(r·min-1) 刀具转速 B | 前进速度 Speed/(m·s-1) | n g l e /(°) 倾斜角度 A |

|---|---|---|---|---|---|

| 粉垄 Vertical smashing rotary tillage | 1.2 | 40 | 0~500 | 0~0.5 | -10~10 |

| 旋耕 Rotary tillage | 1.7 | 20 | 0~600 | 0~0.4 | — |

Table 1 Tillage parameters

| 耕作方式 Tillage method | 耕作幅宽 Tillage width/m | 最大耕深 Tillage depth/cm | l a d e s p e e d /(r·min-1) 刀具转速 B | 前进速度 Speed/(m·s-1) | n g l e /(°) 倾斜角度 A |

|---|---|---|---|---|---|

| 粉垄 Vertical smashing rotary tillage | 1.2 | 40 | 0~500 | 0~0.5 | -10~10 |

| 旋耕 Rotary tillage | 1.7 | 20 | 0~600 | 0~0.4 | — |

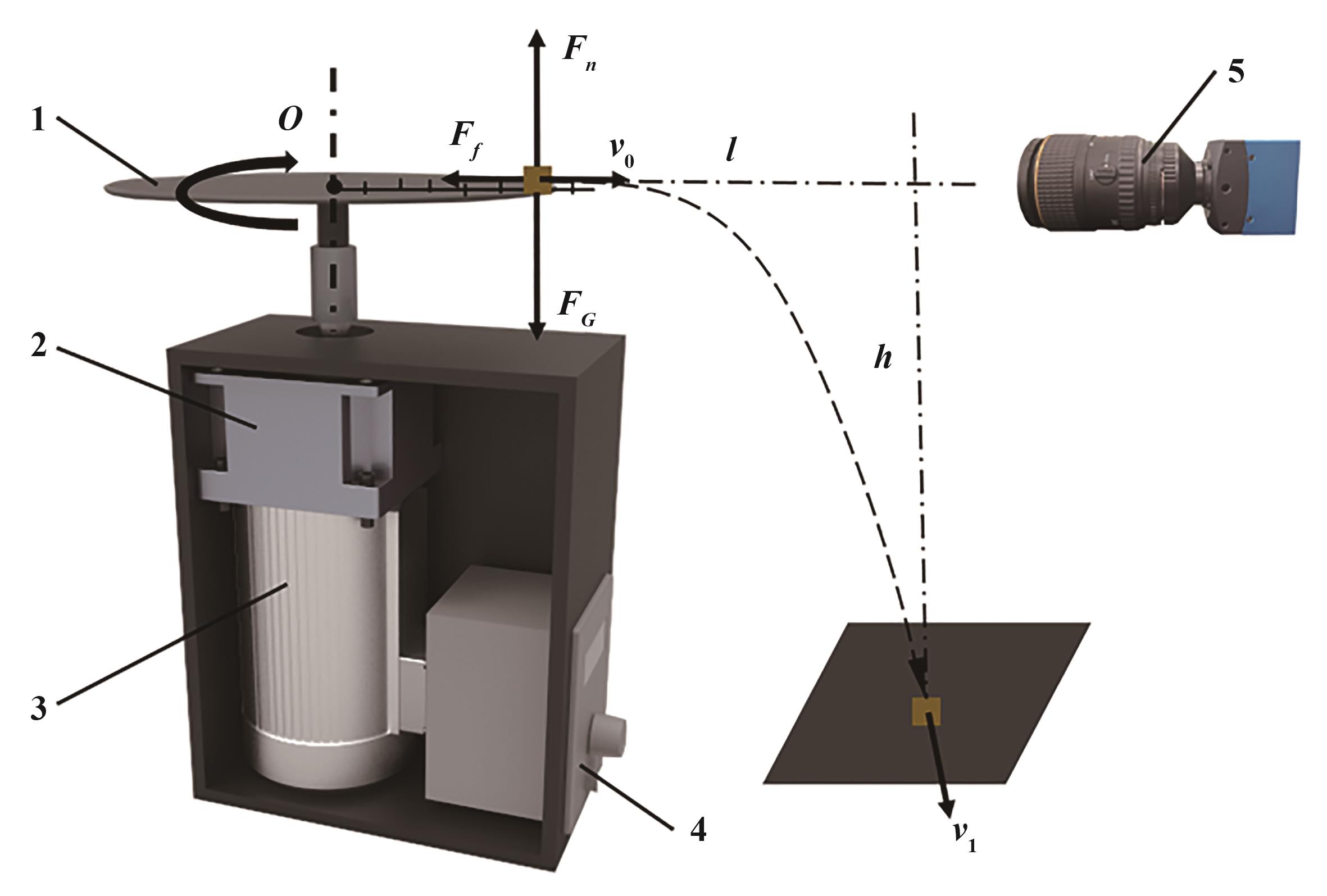

Fig. 1 Coefficient measuring platform and measuring principleNote: 1—Platform (materials could be replaced); 2—Speed reducer; 3—Electrical mach; 4—Speed regulator; 5—Camera with high-speed.

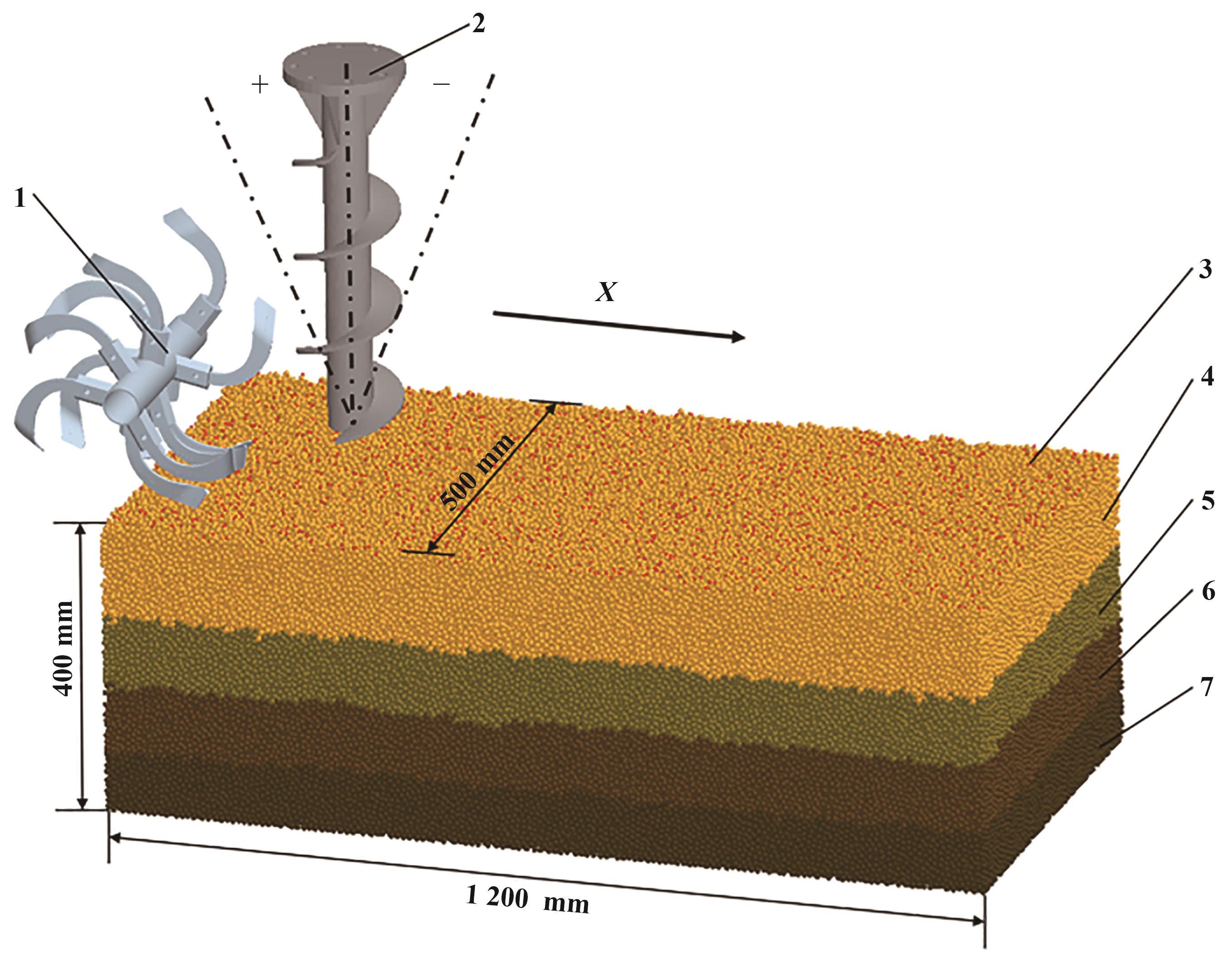

Fig. 2 3D simulation model of tillage processNote: 1—Rotary blade; 2—Powder ridge blade; 3—Fertilizer particles; 4~7 is soil particles at 0—10, 10—20, 20—30, 30—40 cm layers, respectively.

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 1 | 200(-1) | 0.2(-1) | -10(-1) | 0.766 1 |

| 2 | 400(+1) | 0.2(-1) | -10(-1) | 0.679 6 | |

| 3 | 200(-1) | 0.4(+1) | -10(-1) | 0.766 3 | |

| 4 | 400(+1) | 0.4(+1) | -10(-1) | 0.714 9 | |

| 5 | 200(-1) | 0.2(-1) | 10(+1) | 0.585 0 | |

| 6 | 400(+1) | 0.2(-1) | 10(+1) | 0.685 2 | |

| 7 | 200(-1) | 0.4(+1) | 10(+1) | 0.643 8 | |

| 8 | 400(+1) | 0.4(+1) | 10(+1) | 0.701 4 | |

| 9 | 132(-1.68) | 0.3(0) | 0(0) | 0.872 1 | |

| 10 | 468(+1.68) | 0.3(0) | 0(0) | 0.657 0 | |

| 11 | 300(0) | 0.13(-1.68) | 0(0) | 0.473 2 | |

| 12 | 300(0) | 0.47(+1.68) | 0(0) | 0.567 8 | |

| 13 | 300(0) | 0.3(0) | -16.8(-1.68) | 0.580 7 | |

| 14 | 300(0) | 0.3(0) | 16.8(+1.68) | 0.570 6 |

Tab. 2 Design of optimization test

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 1 | 200(-1) | 0.2(-1) | -10(-1) | 0.766 1 |

| 2 | 400(+1) | 0.2(-1) | -10(-1) | 0.679 6 | |

| 3 | 200(-1) | 0.4(+1) | -10(-1) | 0.766 3 | |

| 4 | 400(+1) | 0.4(+1) | -10(-1) | 0.714 9 | |

| 5 | 200(-1) | 0.2(-1) | 10(+1) | 0.585 0 | |

| 6 | 400(+1) | 0.2(-1) | 10(+1) | 0.685 2 | |

| 7 | 200(-1) | 0.4(+1) | 10(+1) | 0.643 8 | |

| 8 | 400(+1) | 0.4(+1) | 10(+1) | 0.701 4 | |

| 9 | 132(-1.68) | 0.3(0) | 0(0) | 0.872 1 | |

| 10 | 468(+1.68) | 0.3(0) | 0(0) | 0.657 0 | |

| 11 | 300(0) | 0.13(-1.68) | 0(0) | 0.473 2 | |

| 12 | 300(0) | 0.47(+1.68) | 0(0) | 0.567 8 | |

| 13 | 300(0) | 0.3(0) | -16.8(-1.68) | 0.580 7 | |

| 14 | 300(0) | 0.3(0) | 16.8(+1.68) | 0.570 6 |

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 15 | 300(0) | 0.3(0) | 0(0) | 0.394 7 |

| 16 | 300(0) | 0.3(0) | 0(0) | 0.369 7 | |

| 17 | 300(0) | 0.3(0) | 0(0) | 0.345 2 | |

| 18 | 300(0) | 0.3(0) | 0(0) | 0.439 7 | |

| 19 | 300(0) | 0.3(0) | 0(0) | 0.449 7 | |

| 20 | 300(0) | 0.3(0) | 0(0) | 0.401 2 | |

| 旋耕耕作 Rotary tillage | 1 | 300(-1) | 0.1(-1) | — | 0.673 4 |

| 2 | 500(+1) | 0.1(-1) | — | 0.727 0 | |

| 3 | 300(-1) | 0.3(+1) | — | 0.618 3 | |

| 4 | 500(+1) | 0.3(+1) | — | 0.526 9 | |

| 5 | 258(-1.68) | 0.2(0) | — | 0.669 7 | |

| 6 | 541(+1.68) | 0.2(0) | — | 0.639 5 | |

| 7 | 400(0) | 0.06(-1.68) | — | 0.637 1 | |

| 8 | 400(0) | 0.34(+1.68) | — | 0.579 5 | |

| 9 | 400(0) | 0.2(0) | — | 0.501 0 | |

| 10 | 400(0) | 0.2(0) | — | 0.530 1 | |

| 11 | 400(0) | 0.2(0) | — | 0.510 9 | |

| 12 | 400(0) | 0.2(0) | — | 0.499 3 | |

| 13 | 400(0) | 0.2(0) | — | 0.529 8 |

Table 2 Design of optimization test

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 15 | 300(0) | 0.3(0) | 0(0) | 0.394 7 |

| 16 | 300(0) | 0.3(0) | 0(0) | 0.369 7 | |

| 17 | 300(0) | 0.3(0) | 0(0) | 0.345 2 | |

| 18 | 300(0) | 0.3(0) | 0(0) | 0.439 7 | |

| 19 | 300(0) | 0.3(0) | 0(0) | 0.449 7 | |

| 20 | 300(0) | 0.3(0) | 0(0) | 0.401 2 | |

| 旋耕耕作 Rotary tillage | 1 | 300(-1) | 0.1(-1) | — | 0.673 4 |

| 2 | 500(+1) | 0.1(-1) | — | 0.727 0 | |

| 3 | 300(-1) | 0.3(+1) | — | 0.618 3 | |

| 4 | 500(+1) | 0.3(+1) | — | 0.526 9 | |

| 5 | 258(-1.68) | 0.2(0) | — | 0.669 7 | |

| 6 | 541(+1.68) | 0.2(0) | — | 0.639 5 | |

| 7 | 400(0) | 0.06(-1.68) | — | 0.637 1 | |

| 8 | 400(0) | 0.34(+1.68) | — | 0.579 5 | |

| 9 | 400(0) | 0.2(0) | — | 0.501 0 | |

| 10 | 400(0) | 0.2(0) | — | 0.530 1 | |

| 11 | 400(0) | 0.2(0) | — | 0.510 9 | |

| 12 | 400(0) | 0.2(0) | — | 0.499 3 | |

| 13 | 400(0) | 0.2(0) | — | 0.529 8 |

| 属性参数 Property parameter | 土壤 Soil | 化肥 Fertilizer | 刀具 Blade | |||

|---|---|---|---|---|---|---|

| 0—10 cm | 10—20 cm | 20—30 cm | 30—40 cm | |||

| 弹性模量 Elastic modulus | 1.820 1×107 | 5.248 4×107 | 6.004 1×107 | 10.457 8×107 | 7.9×1010 | 2.05×1011 |

| 剪切模量 Shear modulus | 0.719 5×107 | 2.016 3×107 | 2.173 7×107 | 3.79 67×107 | 3.16×1010 | 7.9×1010 |

| 泊松比 Poisson ratio | 0.26 | 0.30 | 0.38 | 0.38 | 0.25 | 0.3 |

e n s i t y /(kg·cm-3) 密度 D | 1 414 | 1 559 | 1 602 | 1 613 | 1 670 | 7 861 |

| 含水率 Water content/% | 17.71 | 18.79 | 18.83 | 18.66 | — | — |

Table 3 Material property parameter

| 属性参数 Property parameter | 土壤 Soil | 化肥 Fertilizer | 刀具 Blade | |||

|---|---|---|---|---|---|---|

| 0—10 cm | 10—20 cm | 20—30 cm | 30—40 cm | |||

| 弹性模量 Elastic modulus | 1.820 1×107 | 5.248 4×107 | 6.004 1×107 | 10.457 8×107 | 7.9×1010 | 2.05×1011 |

| 剪切模量 Shear modulus | 0.719 5×107 | 2.016 3×107 | 2.173 7×107 | 3.79 67×107 | 3.16×1010 | 7.9×1010 |

| 泊松比 Poisson ratio | 0.26 | 0.30 | 0.38 | 0.38 | 0.25 | 0.3 |

e n s i t y /(kg·cm-3) 密度 D | 1 414 | 1 559 | 1 602 | 1 613 | 1 670 | 7 861 |

| 含水率 Water content/% | 17.71 | 18.79 | 18.83 | 18.66 | — | — |

| 接触材料 Contact material | 接触参数 Contact parameter | ||

|---|---|---|---|

| 碰撞恢复系数 Coefficient of restitution | 滑动摩擦系数 Dynamic friction factor | 滚动摩擦系数 Coefficient of rolling friction | |

| 土壤-土壤 Soil-soil | 0.103 3 | 0.894 7 | 0.153 5 |

| 土壤-刀具 Soil-blade | 0.139 0 | 0.827 9 | 0.158 4 |

| 化肥-土壤 Fertilizer-soil | 0.066 5 | 0.908 2 | 0.640 0 |

| 化肥-刀具 Fertilizer-blade | 0.293 3 | 0.590 1 | 0.480 5 |

Table 4 Material contact parameter

| 接触材料 Contact material | 接触参数 Contact parameter | ||

|---|---|---|---|

| 碰撞恢复系数 Coefficient of restitution | 滑动摩擦系数 Dynamic friction factor | 滚动摩擦系数 Coefficient of rolling friction | |

| 土壤-土壤 Soil-soil | 0.103 3 | 0.894 7 | 0.153 5 |

| 土壤-刀具 Soil-blade | 0.139 0 | 0.827 9 | 0.158 4 |

| 化肥-土壤 Fertilizer-soil | 0.066 5 | 0.908 2 | 0.640 0 |

| 化肥-刀具 Fertilizer-blade | 0.293 3 | 0.590 1 | 0.480 5 |

| 参数 Parameter | 土层 Soil layer/cm | ||||

|---|---|---|---|---|---|

| 10—20 | 20—30 | 30—40 | |||

| 法向接触刚度 Normal contact stiffness/(N·m-3) | 5.44×107 | 6.22×107 | 1.08×108 | ||

| 切向接触刚度 Tangential contact stiffness/(N·m-3) | 3.63×107 | 4.15×107 | 7.22×107 | ||

| 法向临界应力 Normal critical stress/Pa | 18 776.67 | 30 949.74 | 41 502.30 | ||

| 切向临界应力 Tangential critical stress/Pa | 12 517.78 | 20 633.16 | 27 668.20 | ||

| 土壤颗粒黏结半径 Bonding radius/mm | — | 4.386 3 | — | ||

| 生成黏结键总数 Total number of bonding bonds | — | 1 294 607 | — | ||

Table 5 Bonding model parameter

| 参数 Parameter | 土层 Soil layer/cm | ||||

|---|---|---|---|---|---|

| 10—20 | 20—30 | 30—40 | |||

| 法向接触刚度 Normal contact stiffness/(N·m-3) | 5.44×107 | 6.22×107 | 1.08×108 | ||

| 切向接触刚度 Tangential contact stiffness/(N·m-3) | 3.63×107 | 4.15×107 | 7.22×107 | ||

| 法向临界应力 Normal critical stress/Pa | 18 776.67 | 30 949.74 | 41 502.30 | ||

| 切向临界应力 Tangential critical stress/Pa | 12 517.78 | 20 633.16 | 27 668.20 | ||

| 土壤颗粒黏结半径 Bonding radius/mm | — | 4.386 3 | — | ||

| 生成黏结键总数 Total number of bonding bonds | — | 1 294 607 | — | ||

| 耕作方式 Tillage method | 变异来源 Variation source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | P值P value |

|---|---|---|---|---|---|

| 粉垄耕作Vertical smashing rotary tillage | 模型 Model | 0.39 | 9 | 0.043 | 0.000 3** |

| A | 9.97×10-3 | 1 | 9.97×10-3 | 0.131 6 | |

| B | 6.44×10-3 | 1 | 6.44×10-3 | 0.216 4 | |

| C | 9.26×10-3 | 1 | 9.26×10-3 | 0.144 5 | |

| AB | 4.71×10-5 | 1 | 4.71×10-5 | 0.912 4 | |

| AC | 9.02×10-3 | 1 | 9.02×10-3 | 0.149 3 | |

| BC | 5.57×10-4 | 1 | 5.57×10-4 | 0.706 1 | |

| A2 | 0.290 | 1 | 0.290 | <0.000 1** | |

| B2 | 0.043 | 1 | 0.043 | 0.006 8** | |

| C2 | 0.079 | 1 | 0.079 | 0.001 0** | |

| 失拟项 Lack term | 0.029 | 5 | 5.79×10-3 | 0.092 1 | |

| 纯误差 Pure error | 8.00×10-3 | 5 | 1.60×10-3 | ||

| 旋耕耕作Rotary tillage | 模型 Model | 0.066 | 5 | 0.013 | 0.000 5** |

| A | 8.12×10-4 | 1 | 8.12×10-4 | 0.309 5 | |

| B | 0.014 | 1 | 0.014 | 0.002 6** | |

| AB | 5.25×10-3 | 1 | 5.25×10-3 | 0.027 1* | |

| A2 | 0.035 | 1 | 0.035 | 0.000 2** | |

| B2 | 0.016 | 1 | 0.016 | 0.001 8** | |

| 失拟项 Lack term | 3.83×10-3 | 3 | 1.28×10-3 | 0.237 8 | |

| 纯误差 Pure error | 9.045×10-4 | 4 | 2.26×10-4 |

Table 6 Model analysis of variance

| 耕作方式 Tillage method | 变异来源 Variation source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | P值P value |

|---|---|---|---|---|---|

| 粉垄耕作Vertical smashing rotary tillage | 模型 Model | 0.39 | 9 | 0.043 | 0.000 3** |

| A | 9.97×10-3 | 1 | 9.97×10-3 | 0.131 6 | |

| B | 6.44×10-3 | 1 | 6.44×10-3 | 0.216 4 | |

| C | 9.26×10-3 | 1 | 9.26×10-3 | 0.144 5 | |

| AB | 4.71×10-5 | 1 | 4.71×10-5 | 0.912 4 | |

| AC | 9.02×10-3 | 1 | 9.02×10-3 | 0.149 3 | |

| BC | 5.57×10-4 | 1 | 5.57×10-4 | 0.706 1 | |

| A2 | 0.290 | 1 | 0.290 | <0.000 1** | |

| B2 | 0.043 | 1 | 0.043 | 0.006 8** | |

| C2 | 0.079 | 1 | 0.079 | 0.001 0** | |

| 失拟项 Lack term | 0.029 | 5 | 5.79×10-3 | 0.092 1 | |

| 纯误差 Pure error | 8.00×10-3 | 5 | 1.60×10-3 | ||

| 旋耕耕作Rotary tillage | 模型 Model | 0.066 | 5 | 0.013 | 0.000 5** |

| A | 8.12×10-4 | 1 | 8.12×10-4 | 0.309 5 | |

| B | 0.014 | 1 | 0.014 | 0.002 6** | |

| AB | 5.25×10-3 | 1 | 5.25×10-3 | 0.027 1* | |

| A2 | 0.035 | 1 | 0.035 | 0.000 2** | |

| B2 | 0.016 | 1 | 0.016 | 0.001 8** | |

| 失拟项 Lack term | 3.83×10-3 | 3 | 1.28×10-3 | 0.237 8 | |

| 纯误差 Pure error | 9.045×10-4 | 4 | 2.26×10-4 |

| 耕作方式 Tillage method | 土层 Soil layer/cm | 仿真化肥颗粒数 Number of simulated fertilizer particles | 每层占比 Proportion/% | 实际化肥颗粒数 Actual number of fertilizer particles | 每层占比 Proportion/% | 误差 Error/% |

|---|---|---|---|---|---|---|

| 旋耕 Rotary tillage | 0—10 | 88 | 55.70 | 293 | 60.16 | 4.47 |

| 10—20 | 62 | 39.24 | 149 | 30.60 | 8.65 | |

| 20—30 | 8 | 5.06 | 45 | 9.24 | 4.18 | |

| 粉垄 Vertical smashing rotary tillage | 0—10 | 60 | 41.67 | 150 | 33.63 | 8.03 |

| 10—20 | 48 | 33.33 | 159 | 35.65 | 2.32 | |

| 20—30 | 27 | 18.75 | 81 | 18.16 | 0.59 | |

| 30—40 | 9 | 6.25 | 56 | 12.56 | 6.31 |

Tab. 7 Simulation and verification results of fertilizer particle distribution

| 耕作方式 Tillage method | 土层 Soil layer/cm | 仿真化肥颗粒数 Number of simulated fertilizer particles | 每层占比 Proportion/% | 实际化肥颗粒数 Actual number of fertilizer particles | 每层占比 Proportion/% | 误差 Error/% |

|---|---|---|---|---|---|---|

| 旋耕 Rotary tillage | 0—10 | 88 | 55.70 | 293 | 60.16 | 4.47 |

| 10—20 | 62 | 39.24 | 149 | 30.60 | 8.65 | |

| 20—30 | 8 | 5.06 | 45 | 9.24 | 4.18 | |

| 粉垄 Vertical smashing rotary tillage | 0—10 | 60 | 41.67 | 150 | 33.63 | 8.03 |

| 10—20 | 48 | 33.33 | 159 | 35.65 | 2.32 | |

| 20—30 | 27 | 18.75 | 81 | 18.16 | 0.59 | |

| 30—40 | 9 | 6.25 | 56 | 12.56 | 6.31 |

| 1 | 吴建富,王海辉,刘经荣,等.长期施用不同肥料稻田土壤养分的剖面分布特征[J].江西农业大学学报,2001, 23(1): 54-56. |

| WU J F, WANG H H, LIU J R, et al.. The characters of the profile distribution of nutrients in rice fields after long-term application of different fertilizers [J]. J. Jiangxi Agric. Univ., 2001, 23(1): 54-56. | |

| 2 | 杨庆璐,黄幸媛,王庆杰,等.玉米空间分层施肥装置结构优化与试验[J].农业机械学报,2020, 51(S1): 175-185. |

| YANG Q L, HUANG X Y, WANG Q J, et al.. Structure optimization and experiment of corn layered fertilization device [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1): 175-185. | |

| 3 | ZHANG J, LI F, LIAO P, et al.. Smash ridge tillage strongly influence soil functionality, physiology and rice yield [J]. Saudi J. Biol. Sci., 2020, 28(2), 1297-1307. |

| 4 | 韦本辉,申章佑,周佳,等.粉垄耕作改良盐碱地效果及机理[J].土壤,2020, 52(4):699-703. |

| WEI B H, SHEN Z Y, ZHOU J, et al.. Study on effect and mechanism of improving saline-alkali soil by fenlong tillage [J]. Soils, 2020, 52(4): 699-703. | |

| 5 | 韦本辉,吴延勇,甘秀芹,等.粉垄栽培甘蔗试验增产效果[J].中国农业科学,2011, 44(21): 4544-4550. |

| WEI B H, WU Y Y, GAN X Q, et al.. Yield increase of smash-ridging cultivation of sugarcane [J]. Sci. Agric. Sin., 2011, 44(21): 4544-4550. | |

| 6 | 石丽红,李超,唐海明,等.长期施肥方式对双季稻根系生理特性与产量的影响[J].中国农业大学学报 2021, 26(9): 18-29. |

| SHI L H, LI C, TANG H M, et al.. Effects of different long-term fertilizer management on physiological characteristic of root and yield of rice in double-cropping rice paddy field [J]. J. Chin. Agric. Univ. 2021, 26(9): 18-29. | |

| 7 | 张拥兵,黄军保,李卓,等.限根栽培下不同施肥方式对葡萄果实品质的影响 [J].山西农业科学,2021,49(9): 1110-1113. |

| ZHANG Y B, HUANG J B, LI Z, et al.. Effects of different fertilizer treatments on grape fruit quality under root restriction cultivation [J]. J. Shanxi Agric. Sci., 2021, 49(9): 1110-1113. | |

| 8 | 雷金银,雷晓婷,周丽娜,等.耕作措施对缓坡耕地土壤养分分布及肥料利用率的影响[J].农业工程学报,2020, 36(18): 127-134. |

| LEI J Y, LEI X T, ZHOU L N, et al.. Effects of tillage measures on soil nutrients distribution and fertilizer use efficiency on gentle slope farmland [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(18): 127-134. | |

| 9 | 李超,施伟,姚应方,等.基于离散元的间歇式施肥器的施肥过程[J].江苏农业科学,2021, 49(1): 166-170. |

| LI C, SHI W, YAO Y F, et al.. Fertilization process of batch fertilizer applicator based on discrete element method [J]. Jiangsu Agric. Sci., 2021, 49(1): 166-170. | |

| 10 | 赵春,吴雪梅.基于EDEM离散元法的土肥混合过程分析[J].中国农机化学报,2019, 40(7): 178-182. |

| ZHAO C, WU X M. Analysis of soil fertilizer mixing process based on EDEM discrete element method [J]. J. Chin. Agric. Mechan., 2019, 40(7): 178-182. | |

| 11 | 刘彩玲,黎艳妮,宋建农,等.基于EDEM的离心甩盘撒肥器性能分析与试验[J].农业工程学报,2017,33(14): 32-39. |

| LIU C L, LI Y N, SONG J N, et al.. Performance analysis and experiment on fertilizer spreader with centrifugal swing disk based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(14): 32-39. | |

| 12 | 曾智伟,马旭,曹秀龙,等.离散元法在农业工程研究中的应用现状和展望[J].农业机械学报,2021,52(4): 1-20. |

| ZENG Z W, MA X, CAO X L, et al.. Critical review of applications of discrete element method in agricultural engineering [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(4): 1-20. | |

| 13 | 赵淑红,刘汉朋,侯磊涛,等.基于离散元法的免耕深施肥分段式玉米播种开沟器研制[J].农业工程学报,2021, 37(13): 1-10. |

| ZHAO S H, LIU H P, HOU L T, et al.. Development of deep fertilizing no-tillage segmented maize sowing opener using discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(13): 1-10. | |

| 14 | 胡建平,赵军,潘浩然,等.基于离散元的双轴旋耕机功耗预测模型[J].农业机械学报,2020, 51(S1): 9-16. |

| HU J P, ZHAO J, PAN H R, et al.. Prediction model of double axis rotary power consumption based on discrete element method [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1): 9-16. | |

| 15 | 祝英豪,夏俊芳,曾荣,等.基于离散元的稻板田旋耕功耗预测模型研究[J].农业机械学报,2020, 51(10): 42-50. |

| ZHU Y H, XIA J F, ZENG R, et al.. Prediction model of rotary tillage power consumption in paddy stubble field based on discrete element method [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(10): 42-50. | |

| 16 | 周华,李栋,刘政源,等.秸秆旋埋还田后空间分布效果仿真与试验[J].农业机械学报,2019, 50(9): 69-77. |

| ZHOU H, LI D, LIU Z Y, et al.. Simulation and experiment of spatial distribution effect after straw incorporation into soil by rotary burial [J]. Trans. Chin. Soc. Agric. Mach., 2019, 50(9): 69-77. | |

| 17 | 熊平原,杨洲,孙志全,等.基于离散元法的旋耕刀三向工作阻力仿真分析与试验[J].农业工程学报,2018, 34(18): 113-121. |

| XIONG P Y, YANG Z, SUN Z Q, et al.. Simulation analysis and experiment for three-axis working resistances of rotary blade based on discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(18): 113-121. | |

| 18 | 方会敏,姬长英,张庆怡,等.基于离散元法的旋耕刀受力分析[J].农业工程学报,2016, 32(21): 54-59. |

| FANG H M, JI C Y, ZHANG Q Y, et al.. Force analysis of rotary blade based on distinct element method [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(21): 54-59. | |

| 19 | 郝文录,刘恒新,朱良,等. 农业机械试验条件 测定方法的一般规定: [S].北京:中国标注出版社,2008. |

| 20 | SHI Y Y, XIN S, WANG X C, et al.. Numerical simulation and field tests of minimum-tillage planter with straw smashing and strip laying based on EDEM software [J]. Comput. Electron. Agric., 2019, 166: 105021. |

| 21 | 鲍士旦.土壤农化分析[M].第3版.北京:中国农业出版社,2000:1-495. |

| 22 | 石林榕,赵武云,孙伟.基于离散元的西北旱区农田土壤颗粒接触模型和参数标定[J].农业工程学报,2017, 33(21): 181-187. |

| SHI L R, ZHAO W Y, SUN W. Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(21): 181-187. | |

| 23 | 王宪良,胡红,王庆杰,等.基于离散元的土壤模型参数标定方法[J].农业机械学报,2017, 48(12): 78-85. |

| WANG X L, HU H, WANG Q J, et al.. Calibration method of soil contact characteristic parameters based on DEM theory [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(12): 78-85. | |

| 24 | 石林榕,吴建民,赵武云,等.基于离散单元法农田土壤单轴压缩模型的建立及参数校核[J].中国农业大学学报,2015, 20(4): 174-182. |

| SHI L R, WU J M, ZHAO W Y, et al.. Establishment and parameter verification of farmland soil model in uniaxial compression based on discrete element method [J]. J. Chin. Agric. Univ., 2015, 20(4): 174-182. | |

| 25 | 孙景彬,刘琪,杨福增,等.黄土高原坡地土壤与旋耕部件互作离散元仿真参数标定[J].农业机械学报,2022, 53(1): 63-73. |

| SUN J B, LIU Q, YANG F Z, et al.. Calibration of discrete element simulation parameters of sloping soil on loess plateau and its interaction with rotary tillage components [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(1): 63-73. | |

| 26 | UCGUL M, SAUNDERS C. Simulation of tillage forces and furrow profile during soil-mouldboard plough interaction using discrete element modelling [J]. Biosyst. Eng., 2020, 190:58-70. |

| 27 | 张锋伟,宋学锋,张雪坤,等.玉米秸秆揉丝破碎过程力学特性仿真与试验[J].农业工程学报,2019, 35(9): 58-65. |

| ZHANG F W, SONG X F, ZHANG X K, et al.. Simulation and experiment on mechanical characteristics of kneading and crushing process of corn straw [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(9): 58-65. | |

| 28 | 郝建军,龙思放,李浩,等.机收麻山药离散元模型构建及其仿真参数标定[J].农业工程学报,2019, 35(20): 34-42. |

| HAO J J, LONG S F, LI H, et al.. Development of discrete element model and calibration of simulation parameters for mechanically-harvested yam [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(20): 34-42. | |

| 29 | 肖茂华,汪开鑫,杨望,等.基于东方蝼蛄爪趾的仿生旋耕刀设计与试验[J].农业机械学报,2021, 52(2): 55-63. |

| XIAO M H, WANG K X, YANG W, et al.. Design and experiment of bionic rotary blade based on claw toe of Gryllotalpa orientalis Burmeister [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(2): 55-63. | |

| 30 | 郝建军,龙思放,李建昌,等.麻山药种植田砂壤土流动性离散元模型颗粒放尺效应[J].农业工程学报,2020, 36(21): 56-64. |

| HAO J J, LONG S F, LI J C, et al.. Effect of granular ruler in discrete element model of sandy loam fluidity in Ma yam planting field [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(21): 56-64. | |

| 31 | MAKANGE N R. Prediction of cutting forces and soil behavior with discrete element simulation [J]. Comput. Electron. Agric., 2020, 179: 105848. |

| 32 | 陈新予,史宇亮,陈明东.基于离散元法的甘薯起垄机旋耕刀抛土性能仿真试验[J].农业工程,2021,11(2): 117-120. |

| CHEN X Y, SHI Y L, CHEN M D. Simulation experiment on throwing performance of rotary blade of sweet potato ridger based on discrete element method [J]. Agric. Eng., 2021, 11(2): 117-120. | |

| 33 | 鲍洋清.基于DEM的新型仿生深松铲的研制[D].泰安:山东农业大学,2018. |

| BAO Y Q. Development of a new bionic subsoiler based on DEM [D]. Tai’an: Shandong Agricultural University, 2018. | |

| 34 | 高亮.基于DEM法的旋耕刀具耕作过程分析与研究[D].石家庄:河北科技大学,2017. |

| GAO L. The analysis and research about rotary knife cultivation process based on DEM [D]. Shijiazhuang: Hebei University of Science & Technology, 2017. |

| [1] | Haidong ZHANG, Zhixian TANG, Liyun ZHANG, Qi YU, Chaojun SONG. Optimization of Discrete Elemental Simulation Parameters for Forest Panax pseudoginseng Plantation Red Soil Based on GA-BP-GA [J]. Journal of Agricultural Science and Technology, 2025, 27(9): 120-130. |

| [2] | Jing XU, Han LI, Pinglu CHEN, Jiangni LUO, Chenglu TANG, Muhua LIU. Calibration and Validation of Discrete Element Model for Camelliaoleifera Seed Meal [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 112-121. |

| [3] | Yuanhao HUANG, Lazhen QUAN, Guangfa HU, Wei QUAN, Fanggang SHI. Calibration of Discrete Element Contact Parameters for Various Materials and Soils with Different Moisture Content [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 98-109. |

| [4] | Hongbo WANG, Zhipeng FAN, Wulantuya, Chunguang WANG, Zhe MA. Parameter Calibration of Discrete Element Model for Simulation of Crushed Corn Stalk Screw Conveying [J]. Journal of Agricultural Science and Technology, 2023, 25(3): 96-106. |

| [5] | Miao YU, Haibin ZHOU, Jingtao DING, Hongsheng CHENG, Yujun SHEN, Shengyuan FAN, Xi ZHANG, Jian WANG, Pengxiang XU, Qiongyi CHENG. Calibration of Interparticle Contact Parameters of Kitchen Waste Composition Based on EDEM [J]. Journal of Agricultural Science and Technology, 2023, 25(12): 111-120. |

| [6] | Jianwei YAN, Song WEI, Dongjun HU, Qihe LIU, Fuigui ZHANG. Parameter Calibration of Radish Seeds with Different Filling Particle Radius by DEM [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 119-128. |

| [7] | XIANG Wei1,2, WU Mingliang1*, LYU Jiangnan2, MA Lan2, QUAN Wei1, LIU Jiajie2, XIAO Le3. Simulation and Experiment on Hole-forming Performance of Hole-forming Mechanism for Rape Seedling Transplanting Based on EDEM [J]. Journal of Agricultural Science and Technology, 2019, 21(7): 70-81. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号