中国农业科技导报 ›› 2024, Vol. 26 ›› Issue (4): 87-96.DOI: 10.13304/j.nykjdb.2022.0937

收稿日期:2022-10-31

接受日期:2022-12-15

出版日期:2024-04-15

发布日期:2024-04-23

作者简介:李明 E-mail:nylm@imau.edu.cn

基金资助:

Ming LI( ), Shuai DONG, Yongqiang PANG, Jiehua YAN, Wangzhong YE

), Shuai DONG, Yongqiang PANG, Jiehua YAN, Wangzhong YE

Received:2022-10-31

Accepted:2022-12-15

Online:2024-04-15

Published:2024-04-23

摘要:

为解决风沙土改良设备研制中存在的核心问题,探讨混拌刀具与风沙土-改土材料间相互作用机理,以国标旋耕刀IT245为基础,分析其作用原理,在此基础上设计了专用于风沙土改良的混拌刀具,通过离散元仿真模拟及室内沙槽试验,以改土材料体积比为评价指标对国标刀及专用刀具5层深度下的混拌效果进行分析。结果显示,风沙土混拌刀具偏转角度越大,改土材料体积比越大,当深度150—120 mm、偏转角为60°时达到最大值(35.67%);风沙土混拌刀具弯折角越大,改土材料体积比越大,当深度150—120 mm、弯折角为130°时达到最大值(36.02%)。风沙土混拌刀具与国标旋耕刀IT245混拌效果相比,深度越浅,改土材料体积比越大,混合效果越好,在深度90—60、60—30 mm时,偏转角60°的风沙土混拌刀具作业后改土材料体积比分别比IT245增加了3.19%、5.11%。研究结果为风沙土混拌刀具及风沙土治理机械的设计与优化提供依据。

中图分类号:

李明, 董帅, 庞永强, 燕洁华, 叶汪忠. 风沙土混拌刀具的改良设计与试验[J]. 中国农业科技导报, 2024, 26(4): 87-96.

Ming LI, Shuai DONG, Yongqiang PANG, Jiehua YAN, Wangzhong YE. Design Improvement and Test of Aeolian Sand Mixing Cutter[J]. Journal of Agricultural Science and Technology, 2024, 26(4): 87-96.

D:粒径 Particle size/mm | 占比 Proportion/% |

|---|---|

| D<0.075 | 0.65 |

| 0.075≤D<0.250 | 43.51 |

| 0.250≤D<0.500 | 53.47 |

| 0.500≤D<1.000 | 2.33 |

| 1.000≤D<2.000 | 0.02 |

| D≥2.000 | 0.02 |

表1 风沙土粒径及占比

Table 1 Particle size and proportion of aeolian sand

D:粒径 Particle size/mm | 占比 Proportion/% |

|---|---|

| D<0.075 | 0.65 |

| 0.075≤D<0.250 | 43.51 |

| 0.250≤D<0.500 | 53.47 |

| 0.500≤D<1.000 | 2.33 |

| 1.000≤D<2.000 | 0.02 |

| D≥2.000 | 0.02 |

| 相互作用材料Interacting material | 碰撞恢复系数 Recovery coefficient | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient |

|---|---|---|---|

风沙土-风沙土 Aeolian sand-aeolian sand | 0.3 | 0.25 | 0.05 |

风沙土-改土材料 Aeolian sand-soil modification material | 0.5 | 0.5 | 0.05 |

改土材料-改土材料 Soil modification material-soil modification material | 0.23 | 0.6 | 0.05 |

风沙土-钢 Aeolian sand-steel | 0.5 | 0.45 | 0.01 |

改土材料-钢 Soil modification material-steel | 0.3 | 0.3 | 0.01 |

表2 材料接触参数

Table 2 Material contact parameters

| 相互作用材料Interacting material | 碰撞恢复系数 Recovery coefficient | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient |

|---|---|---|---|

风沙土-风沙土 Aeolian sand-aeolian sand | 0.3 | 0.25 | 0.05 |

风沙土-改土材料 Aeolian sand-soil modification material | 0.5 | 0.5 | 0.05 |

改土材料-改土材料 Soil modification material-soil modification material | 0.23 | 0.6 | 0.05 |

风沙土-钢 Aeolian sand-steel | 0.5 | 0.45 | 0.01 |

改土材料-钢 Soil modification material-steel | 0.3 | 0.3 | 0.01 |

材料 Material | 泊松比 Poisson’s ratio | 剪切模量 Shear modulus/MPa | 密度 Density/(kg·m-3) |

|---|---|---|---|

风沙土 Aeolian sand | 0.3 | 11.5 | 2 650 |

改土材料 Soil modification material | 0.4 | 1 | 241 |

钢 steel | 0.3 | 7.9×104 | 7 850 |

表3 材料本征参数

Table 3 Material intrinsic parameters

材料 Material | 泊松比 Poisson’s ratio | 剪切模量 Shear modulus/MPa | 密度 Density/(kg·m-3) |

|---|---|---|---|

风沙土 Aeolian sand | 0.3 | 11.5 | 2 650 |

改土材料 Soil modification material | 0.4 | 1 | 241 |

钢 steel | 0.3 | 7.9×104 | 7 850 |

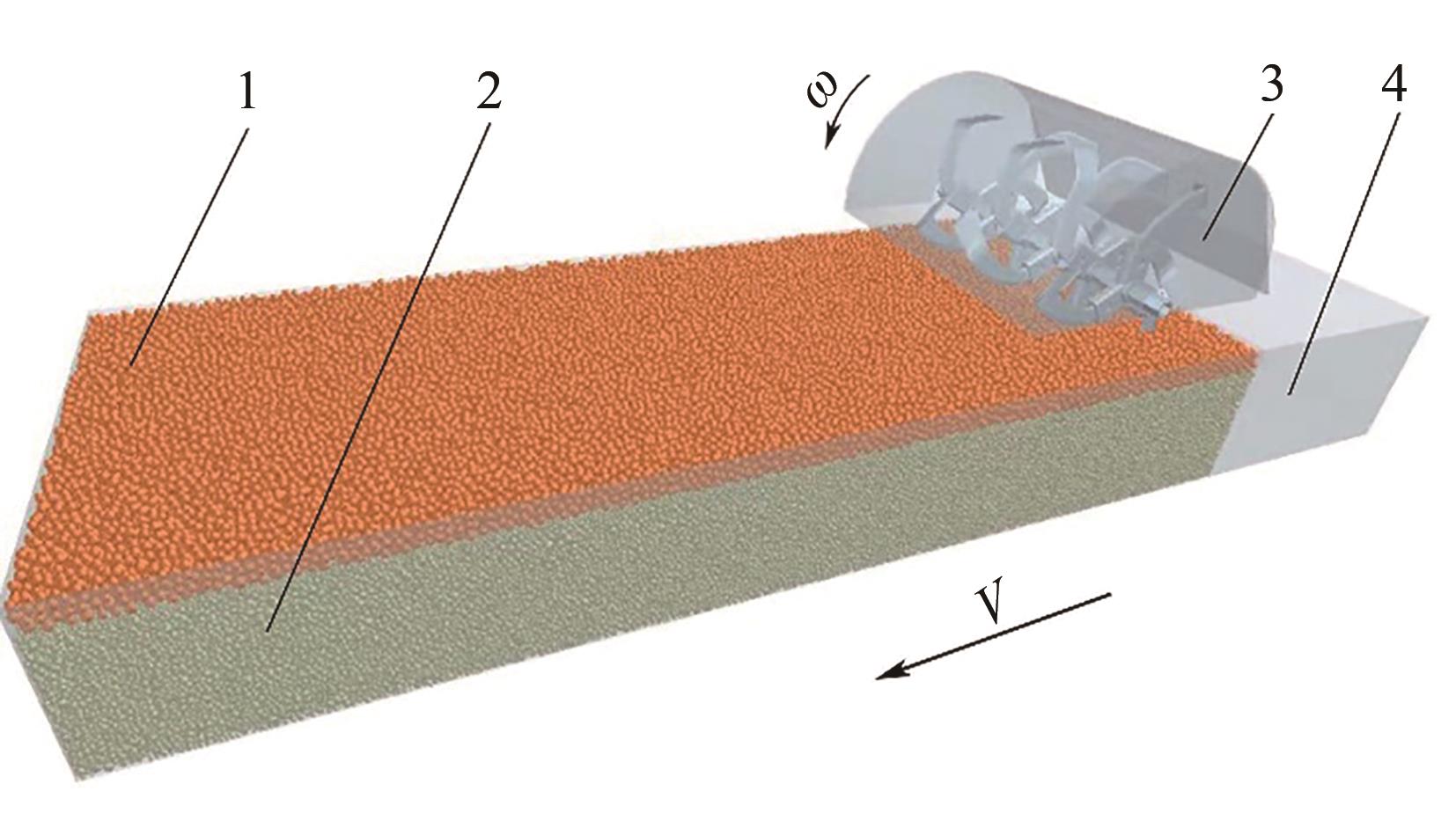

图6 混拌试验仿真模型注:1—改土材料;2—风沙土;3—沙槽;4—混拌设备。

Fig. 6 Simulation model of mixing testNote:1—Soil modification material; 2—Aeolian sand; 3—Sand trough;4—Mixing equipment.

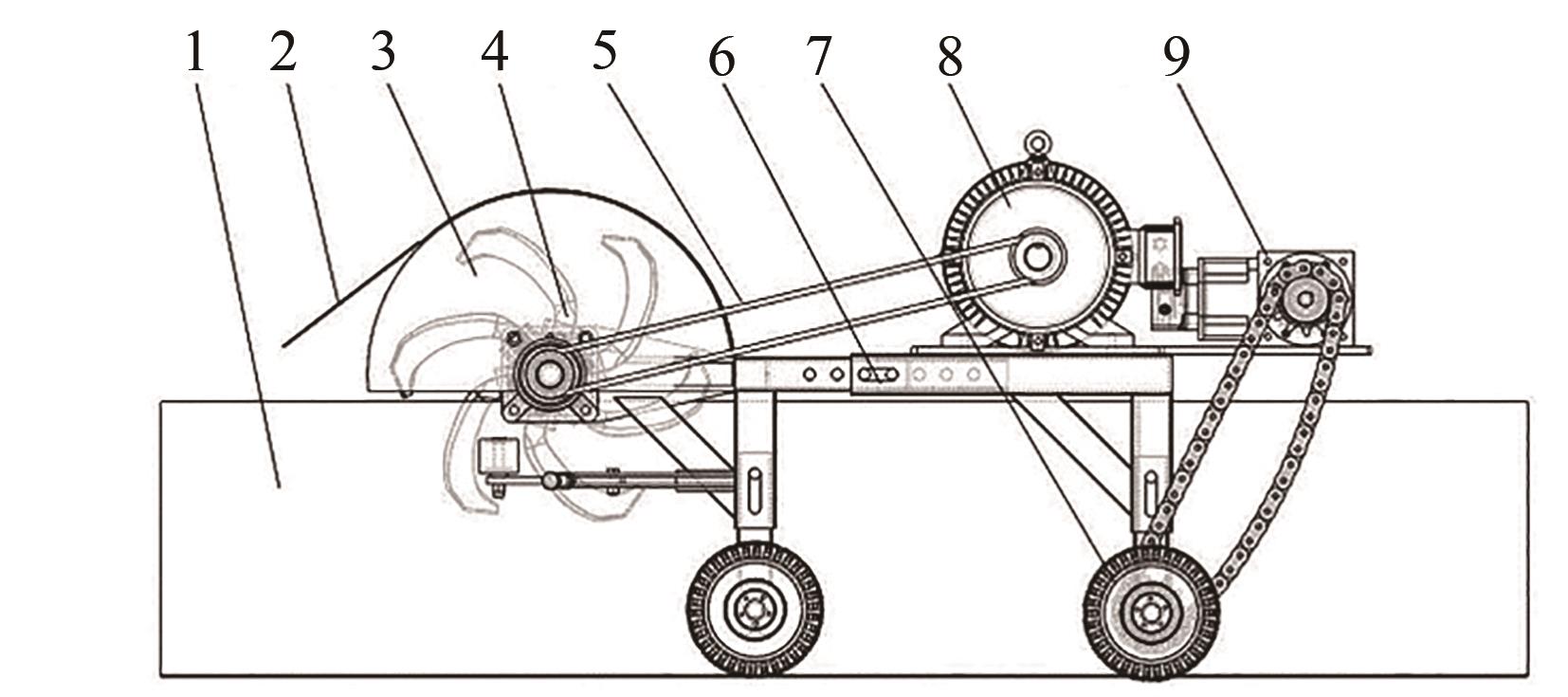

图7 风沙土混拌试验台注:1—沙槽;2—挡沙板(角度可调); 3—外罩; 4—旋耕刀辊; 5—传动皮带;6—机架;7—行进轮;8—拖动电机;9—行走减速机构。

Fig. 7 Sand soil mixing test benchNote:1—Sand trough; 2—Sand deflector (angle adjustable); 3— Cover; 4—Rotary blade roller; 5—Drive belt; 6—Frame; 7—Traveling wheel; 8—Driving motor; 9—Traveling deceleration mechanism.

| 1 | 杜宇佳,高广磊,陈丽华,等.土壤微生物膜对风沙土固沙保水特性的影响[J].农业工程学报, 2020, 36(17): 98-105. |

| DU Y J, GAO G L, CHEN L H, et al.. Effects of soil microbial films on sand fixation and water retention characteristics of aeolian soils [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(17): 98-105. | |

| 2 | 杨凯,唐泽军,赵智,等.粉煤灰和聚丙烯酰胺固沙效果的风洞试验[J].农业工程学报, 2012, 28(179): 54-59. |

| YANG K, TANG Z J, ZHAO Z, et al.. Wind tunnel experimental study on sand-fixing effect of fly ash and polyacrylamide [J]. Trans. Chin. Soc. Agric. Eng., 2012, 28(179): 54-59. | |

| 3 | 陈艺文,李红丽,董智,等.3种固沙材料与风沙土复配后土壤改良效应及其质量评价[J].水土保持研究, 2022, 29(5): 48-54. |

| CHEN Y W, LI H L, DONG Z, et al.. Soil improvement effect and quality evaluation of three sand-fixing materials combined with aeolian sandy soil [J]. Res. Soil Water Conservation, 2022, 29(5): 48-54. | |

| 4 | 顾美英,唐光木,葛春辉,等.不同秸秆还田方式对和田风沙土土壤微生物多样性的影响[J].中国生态农业学报, 2016, 24(4): 489-498. |

| GU M Y, TANG G M, GE C H, et al.. Effects of straw incorporation modes on microbial activity and functional diversity in sandy soil [J]. Chin. J. Eco-Agric., 2016, 24(4): 489-498. | |

| 5 | PARDO G S, ORENSE R P, SARMAH A K, et al.. Cyclic strength of sand mixed with biochar:some preliminary results [J]. Soils Foundations, 2018, 58(1): 241-247. |

| 6 | FU G, QIU X, XU X, et al.. The role of biochar particle size and application rate in promoting the hydraulic and physical properties of sandy desert soil [J]. Catena, 2021, 207(1): 105-115. |

| 7 | RITURAJ D, ANANT A D, RAVI K, et al.. Applications of bio-cementation and bio-polymerization for aeolian erosion control [J]. J. Arid Environ., 2021, 187(7): 104-116. |

| 8 | JIANG S, YE Y, HE M, et al.. Mixing uniformity of irregular sand and gravel materials in a rotating drum with determination of contact model parameters [J]. Powder Technol., 2019, 354(9): 377-391. |

| 9 | ZHOU L, GAO J, HU C, et al.. Numerical simulation and testing verification of the interaction between track and sandy ground based on discrete element method [J]. J. Terramech., 2021, 95(2): 73-88. |

| 10 | 赵淑红,刘汉朋,杨超,等.玉米秸秆还田交互式分层深松铲设计与离散元仿真[J].农业机械学报, 2021, 52(3): 75-87. |

| ZHAO S H, LIU H P, YANG C, et al.. Design and discrete element simulation of interactive layered subsoiler with maize straw returned to filed [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(3): 75-87. | |

| 11 | 曾智伟,马旭,曹秀龙,等.离散元法在农业工程研究中的应用现状和展望[J].农业机械学报, 2021, 52(4): 1-20. |

| ZENG Z W, MA X, CAO X L, et al.. Critical review of applications of discrete element method in agricultural engineering [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(4): 1-20. | |

| 12 | 方会敏,姬长英, AHMED A T,等.秸秆-土壤-旋耕刀系统中秸秆位移仿真分析[J].农业机械学报, 2016, 47(1): 60-67. |

| FANG H M, JI C Y, AHMED A T, et al.. Simulation analysis of straw movement in straw-soil-rotary blade system [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(1): 60-67. | |

| 13 | 徐高明,丁启朔,汪小旵,等.秸秆-土壤-旋耕机交互下秸秆位移与埋覆效果研究[J].农业机械学报, 2022, 53(7): 23-29. |

| XU G M, DING Q S, WANG X C, et al.. Analysis of straw displacement and burying effect in straw-soil-rotary tiller interaction [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(7): 23-29. | |

| 14 | 杨玉婉,佟金,马云海,等.鼹鼠多趾结构特征仿生旋耕刀设计与试验[J].农业工程学报, 2019, 35(19): 37-45. |

| YANG Y W, TONG J, MA Y H, et al.. Design and experiment of biomimetic rotary tillage blade based on multiple claws characteristics of mole rats [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(19): 37-45. | |

| 15 | 张智泓,甘帅汇,左国标,等. 以砂鱼蜥头部为原型的仿生深松铲尖设计与离散元仿真[J]. 农业机械学报, 2021, 52(9): 33-42. |

| ZHANG Z H, GAN S H, ZUO G B, et al.. Bionic design and performance experiment of sandfish head inspired subsoiler tine [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(9): 33-42. | |

| 16 | 吴硕,李萍萍,张西良,等.基于离散元法的番茄秸秆立式螺旋混合机理[J].排灌机械工程学报, 2018, 36(8): 719-724. |

| WU S, LI P P, ZHANG X L, et al.. Vertical spiral mixing mechanism of tomato straw particles based on discrete element method [J]. J. Drainage Irrig. Mach. Eng., 2018, 36(8): 719-724. | |

| 17 | OLIESLAGER R, RAOMON H, DE B J. Calculation of fertilizer distribution patterns from a spinning disc spreader by means of a simulation model [J]. J. Agric. Eng. Res., 1996, 63(2): 137-152. |

| 18 | SU N, XU T, SONG L, et al.. Variable rate fertilization system with adjustable active feed-roll length [J]. Int. J. Agric. Biol. Eng., 2015, 8(4): 19-26. |

| 19 | 王德福.双轴卧式全混合日粮混合机的混合机理分析[J].农业机械学报, 2006, 45(8): 178-182. |

| WANG D F. Analysis of mixing principle on twin-shaft horizontal total mixed ration mixer [J]. Trans. Chin. Soc. Agric. Mach., 2006, 45(8): 178-182. | |

| 20 | 戚华彪,周光正,于福海,等.颗粒物质混合行为的离散单元法研究[J].化学进展, 2015, 27(1): 113-124. |

| QI H B, ZHOU G Z, YU F H, et al.. Researches on mixing of granular materials with discrete element method [J]. Prog. Chem., 2015, 27(1): 113-124. | |

| 21 | 肖茂华,汪开鑫,杨望,等.基于东方蝼蛄爪趾的仿生旋耕刀设计与试验[J].农业机械学报, 2021, 52(2): 55-63. |

| XIAO M H, WANG K X, YANG W, et al.. Design and experiment of bionic rotary blade based on claw toe of Gryllotalpa orientalis Burmeister [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(2): 55-63. | |

| 22 | 董向前,苏辰,郑慧娜,等.基于DEM-MBD耦合算法的振动深松土壤扰动过程分析[J].农业工程学报, 2022, 38(1): 34-43. |

| DONG X Q, SU C, ZHENG H N, et al.. Analysis of soil disturbance process by vibrating subsoiling based on DEM-MBD coupling algorithm [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(1): 34-43. | |

| 23 | 中国农业机械化科学研究院.农业机械设计手册(上册)[M].北京: 中国农业科学技术出版社, 2007:228-249. |

| China Academy of Agricultural Mechanization Sciences. Agricultural Machinery Design Manual (Volume Ⅰ) [M]. Beijing: China Agricultural Science and Technology Press, 2007: 228-249. | |

| 24 | 熊平原,杨洲,孙志全,等.基于离散元法的旋耕刀三向工作阻力仿真分析与试验[J].农业工程学报, 2018, 34(18): 113-121. |

| XIONG P Y, YANG Z, SUN Z Q, et al.. Simulation analysis and experiment for three-axis working resistances of rotary blade based on discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(18): 113-121. | |

| 25 | 朱留宪.基于SPH算法的微耕机旋耕刀有限元仿真与优化[D].重庆: 西南大学, 2012. |

| ZHU L X. Finite element simulation and optimization of rotary blade of mini-tiller based on SPH algorithm [D]. Chongqing: Southwest University, 2012. | |

| 26 | 张锐,韩佃雷,吉巧丽,等.离散元模拟中沙土参数标定方法研究[J].农业机械学报, 2017, 48(3): 49-56. |

| ZHANG R, HAN D L, JI Q L, et al.. Calibration methods of sandy soil parameters in simulation of discrete element method [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(3): 49-56. | |

| 27 | 田辛亮,丛旭,齐江涛,等.黑土区玉米秸秆-土壤混料离散元模型参数标定[J].农业机械学报, 2021, 52(10): 100-108, 242. |

| TIAN X L, CONG X, QI J T, et al.. Parameter calibration of discrete element model for corn straw-soil mixture in black soil areas [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(10): 100-108, 242. | |

| 28 | 张晋.旋耕机正转深旋节能技术研究[D].北京: 中国农业科学院, 2021. |

| ZHANG J. Chinese Academy of Agricultural Sciences Thesis [D]. Beijing: Chinese Academy of Agricultural Sciences, 2021. | |

| 29 | 王振兴. 轨道除沙车铲板与沙土相互作用机理研究[D]. 石家庄: 石家庄铁道大学, 2019. |

| WANG Z X. Study of Interaction Mechanism between Shovel of Track Sand Removal Vehicle and Sand [D]. Shijiazhuang: Shijiazhuang Tiedao University, 2019. | |

| 30 | 王韦韦,蔡丹艳,谢进杰,等.玉米秸秆粉料致密成型离散元模型参数标定[J].农业机械学报, 2021, 52(3): 127-134. |

| WANG W W, CAI D Y, XIE X J, et al.. Parameters calibration of discrete element model for corn stalk powder compression simulation [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(3): 127-134. |

| [1] | 张海东, 唐志贤, 张立芸, 于淇, 宋朝君. 基于GA-BP-GA优化林下三七种植红壤离散元仿真参数[J]. 中国农业科技导报, 2025, 27(9): 120-130. |

| [2] | 奚小波, 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏. 一种果园中耕避障除草机的设计与试验[J]. 中国农业科技导报, 2025, 27(7): 101-110. |

| [3] | 许静, 李晗, 陈平录, 罗江旎, 唐承露, 刘木华. 油茶茶枯离散元模型参数标定与试验[J]. 中国农业科技导报, 2025, 27(3): 112-121. |

| [4] | 冯长龙, 黄春光, 宁辰阳, 李树平, 陈科锦. 植树机挖坑机构螺旋式钻头性能特性优化研究[J]. 中国农业科技导报, 2025, 27(2): 89-98. |

| [5] | 田祥州, 贺福强, 陈发江, 詹璐歆. 基于休止角标定不同含水率木粉离散元参数[J]. 中国农业科技导报, 2025, 27(1): 118-128. |

| [6] | 顿国强, 王雷, 纪欣鑫, 姜新波, 赵宇, 郭娜. 金乡紫皮蒜种离散元参数标定与试验验证[J]. 中国农业科技导报, 2024, 26(8): 131-139. |

| [7] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [8] | 黄元昊, 全腊珍, 胡广发, 全伟, 石方刚. 多种材料与不同含水率土壤的离散元接触参数标定[J]. 中国农业科技导报, 2024, 26(3): 98-109. |

| [9] | 陈林, 余南辉, 王立宗, 范吉军, 雷港, 刘晓鹏, 周龙, 周劲. 米糠和碎米的接触参数测量与离散元仿真标定[J]. 中国农业科技导报, 2024, 26(2): 127-136. |

| [10] | 丛文成, 袁立敏, 蒙仲举, 杨宇. 玉米芯颗粒对风沙土毛管水运移和蒸发特性的影响[J]. 中国农业科技导报, 2024, 26(2): 198-207. |

| [11] | 杨大芳, 李飞翔, 葛越锋, 李奕辰. 基于离散元法的外槽轮排肥器排肥性能研究[J]. 中国农业科技导报, 2024, 26(12): 88-97. |

| [12] | 王洪波, 樊志鹏, 乌兰图雅, 王春光, 马哲. 揉碎玉米秸秆螺旋输送仿真离散元模型参数标定[J]. 中国农业科技导报, 2023, 25(3): 96-106. |

| [13] | 于淼, 周海宾, 丁京涛, 程红胜, 沈玉君, 范盛远, 张曦, 王健, 徐鹏翔, 程琼仪. 基于EDEM的餐厨垃圾组成颗粒间接触参数标定[J]. 中国农业科技导报, 2023, 25(12): 111-120. |

| [14] | 马紫涛, 赵智豪, 全伟, 石方刚, 高晨, 吴明亮. 基于EDEM的水稻残茬秸秆离散元仿真参数标定[J]. 中国农业科技导报, 2023, 25(11): 103-113. |

| [15] | 单发科, 康朔, 朱建锡, 王永维, 王俊. 基于EDEM的粉垄和旋耕作业混肥效果研究[J]. 中国农业科技导报, 2023, 25(11): 90-102. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||