中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (3): 96-106.DOI: 10.13304/j.nykjdb.2022.0725

收稿日期:2022-08-31

接受日期:2022-10-24

出版日期:2023-03-15

发布日期:2023-05-22

作者简介:王洪波 E⁃mail:wanghb@imau.edu.cn

基金资助:

Hongbo WANG( ), Zhipeng FAN, Wulantuya, Chunguang WANG, Zhe MA

), Zhipeng FAN, Wulantuya, Chunguang WANG, Zhe MA

Received:2022-08-31

Accepted:2022-10-24

Online:2023-03-15

Published:2023-05-22

摘要:

为进一步揭示揉碎玉米秸秆饲料在螺旋输送器中的输送机理,提高揉碎玉米秸秆螺旋输送过程中离散元仿真研究所用参数的准确度,将揉碎玉米秸秆分为秸秆穰、秸秆叶、秸秆皮,采用物理试验和仿真优化设计相结合的方法对离散元仿真参数进行标定。首先,通过物理试验得到穰、叶、皮各项本征参数和接触参数的平均值和范围,将范围相对较大的接触参数通过Plackett-Burman试验利用其显著性进行筛选。结果表明,对仿真堆积角影响显著的因素有穰-叶滚动摩擦系数、皮-叶滚动摩擦系数、叶-叶静摩擦系数。对这3个显著性参数进行最陡爬坡试验,将其取值范围进行优化缩小,通过Box-Behnken试验建立堆积角与显著性参数的二阶回归模型,堆积角的目标值设置为物理试验测得的30.4°,寻优得到最佳的显著性参数的取值:叶-穰滚动摩擦系数为0.325,皮-叶滚动摩擦系数为0.377,叶-叶静摩擦系数为0.411,在此组合下仿真堆积角为30.77°。为进一步检验参数取值的准确性,通过t检验得到P>0.05,表明仿真与物理试验堆积角的值无明显差异,验证了最佳参数取值的可靠性。由此表明,应用上述各物理试验和优化试验来测定及标定离散元仿真参数是可行的,同时标定的参数为揉碎玉米秸秆的其他仿真试验提供了参考。

中图分类号:

王洪波, 樊志鹏, 乌兰图雅, 王春光, 马哲. 揉碎玉米秸秆螺旋输送仿真离散元模型参数标定[J]. 中国农业科技导报, 2023, 25(3): 96-106.

Hongbo WANG, Zhipeng FAN, Wulantuya, Chunguang WANG, Zhe MA. Parameter Calibration of Discrete Element Model for Simulation of Crushed Corn Stalk Screw Conveying[J]. Journal of Agricultural Science and Technology, 2023, 25(3): 96-106.

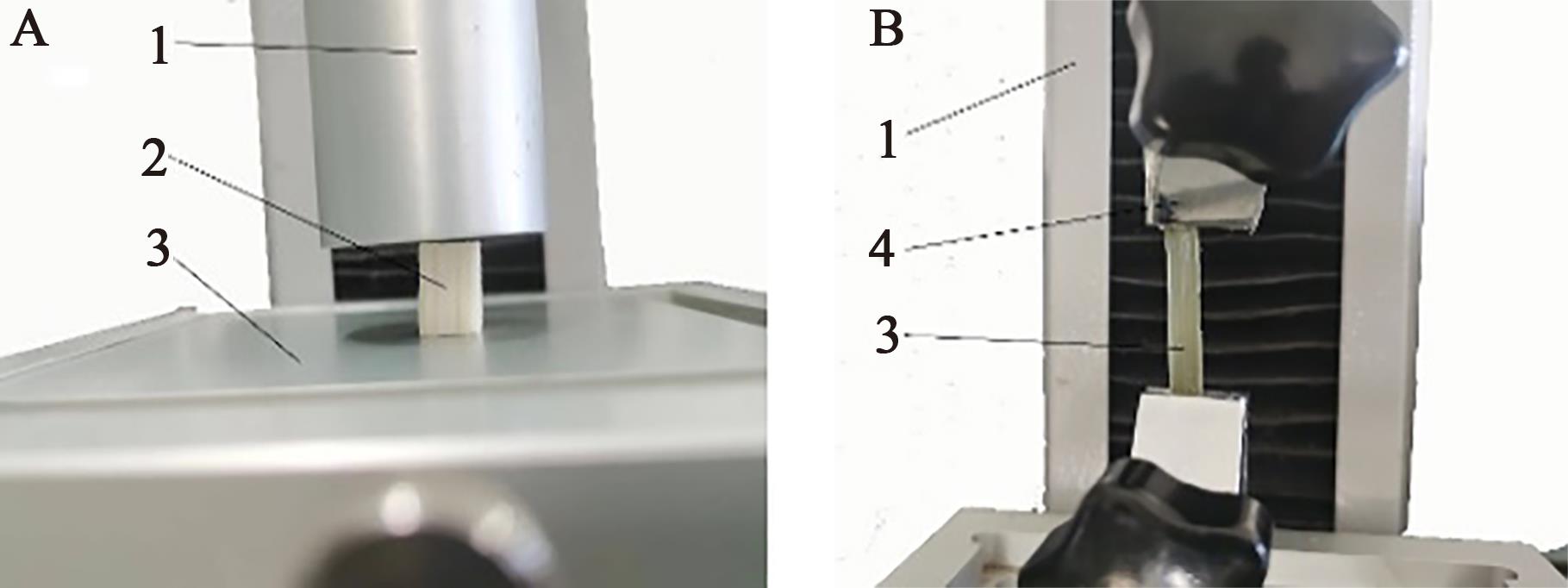

图1 穰和叶的弹性模量测定A:穰的剪切试验;B:叶的剪切试验;1—质构仪刀具;2—穰;3—底板;4—叶

Fig. 1 Determination of elastic modulus of straw core and leafA: Shear test of straw core; B: Shear test of leaves; 1—Texture analyzer cutter; 2—Straw core; 3—Bottom plate; 4—Leaf

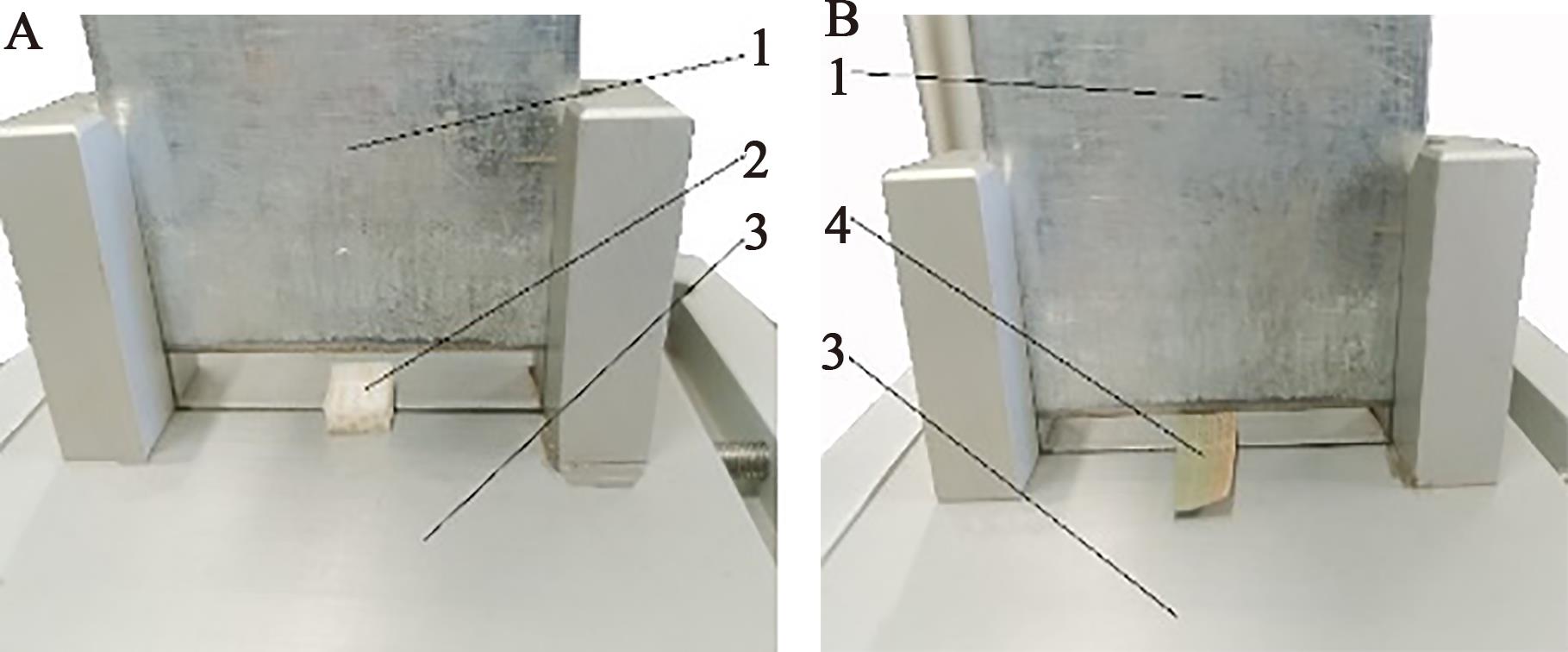

图2 穰和叶的剪切模量测定A:穰的剪切试验;B:叶的剪切试验;1—质构仪刀具;2具穰;3;底板;4—叶

Fig. 2 Shear modulus determination of straw core and leafA: Shear test of straw core; B: Shear test of leaves; 1—Texture analyzer cutter; 2—Straw core; 3—Bottom plate; 4—Leaf

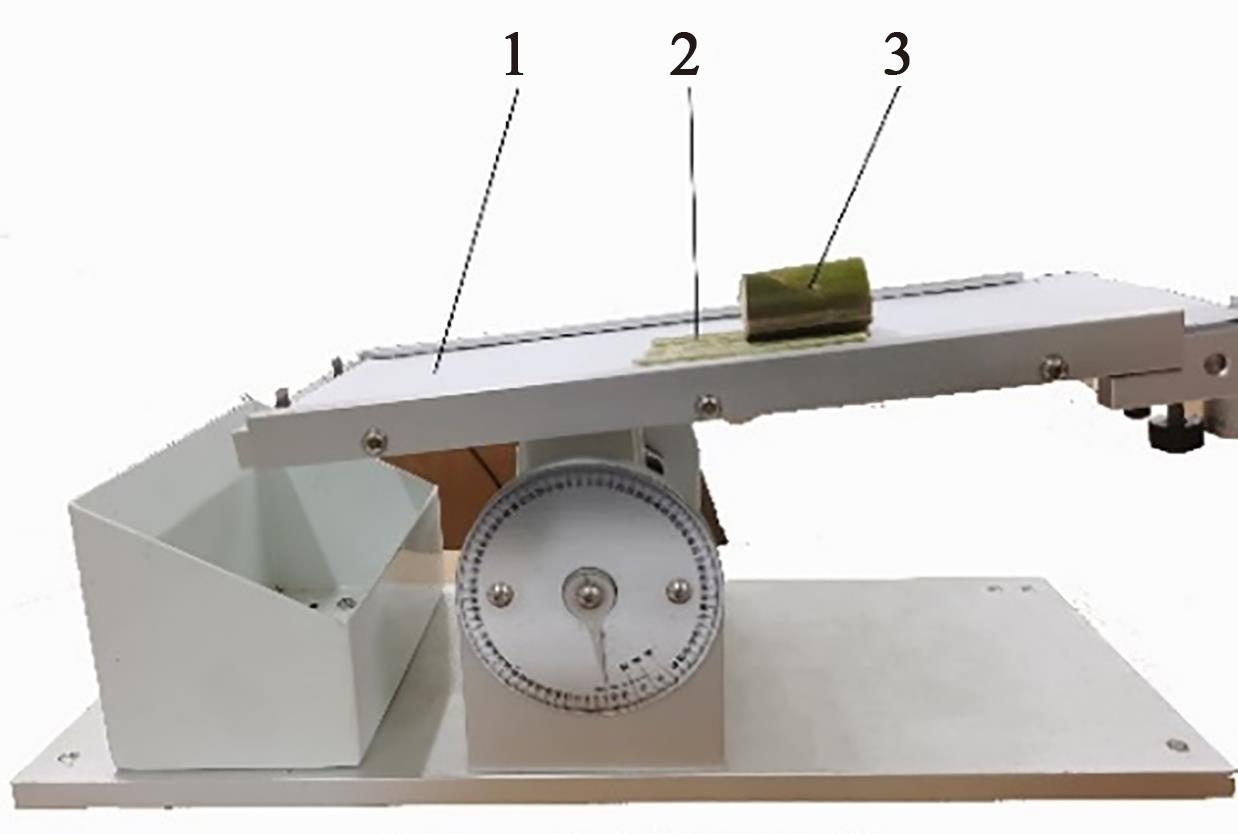

图3 叶与皮的静摩擦系数测定装置注:1—斜面仪;2—叶制作的底板;3—皮。

Fig. 3 Determination test of static friction coefficient between leaf and skinNote: 1—Inclinometer; 2—Base plate made of leaf; 3—Skin.

对象 Object | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient | 碰撞恢复系数 Collision restitution coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

穰 Straw core | 叶 Leaf | 皮 Skin | 穰 Straw core | 叶 Leaf | 皮 Skin | 穰 Straw core | 叶 Leaf | 皮 Skin | |

穰 Straw core | 2.25~3.08 | 0.23~0.36 | 0.36~0.42 | ||||||

叶 Leaf | 0.75~1.04 | 0.31~0.40 | 0.27~0.36 | 0.29~0.38 | 0.29~0.38 | 0.29~0.40 | |||

皮 Skin | 0.78~1.04 | 0.31~0.40 | 0.62~0.75 | 0.31~0.38 | 0.29~0.42 | 0.27~0.32 | 0.36~0.43 | 0.36~0.41 | 0.33~0.43 |

45钢 45 steel | 1.00~1.07 | 0.36~0.40 | 0.31~0.34 | 0.31~0.42 | 0.18~0.25 | 0.25~0.29 | 0.37~0.46 | 0.36~0.43 | 0.40~0.45 |

表1 各对象相互之间的静摩擦系数

Table 1 Static friction coefficient, rolling friction coefficient and collision restitution coefficient between objects

对象 Object | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient | 碰撞恢复系数 Collision restitution coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

穰 Straw core | 叶 Leaf | 皮 Skin | 穰 Straw core | 叶 Leaf | 皮 Skin | 穰 Straw core | 叶 Leaf | 皮 Skin | |

穰 Straw core | 2.25~3.08 | 0.23~0.36 | 0.36~0.42 | ||||||

叶 Leaf | 0.75~1.04 | 0.31~0.40 | 0.27~0.36 | 0.29~0.38 | 0.29~0.38 | 0.29~0.40 | |||

皮 Skin | 0.78~1.04 | 0.31~0.40 | 0.62~0.75 | 0.31~0.38 | 0.29~0.42 | 0.27~0.32 | 0.36~0.43 | 0.36~0.41 | 0.33~0.43 |

45钢 45 steel | 1.00~1.07 | 0.36~0.40 | 0.31~0.34 | 0.31~0.42 | 0.18~0.25 | 0.25~0.29 | 0.37~0.46 | 0.36~0.43 | 0.40~0.45 |

代号 Code | 仿真参数 Simulation parameter | 水平 Level | 代号 Code | 仿真参数 Simulation parameter | 水平 Level | ||

|---|---|---|---|---|---|---|---|

| -1 | +1 | -1 | +1 | ||||

| A | 穰-穰静摩擦系数 Straw corestraw core static friction coefficient | 2.14 | 3.27 | G | 皮-皮静摩擦系数 Skinskin static friction coefficient | 0.58 | 0.75 |

| B | 穰-穰滚动摩擦系数 Straw corestraw core rolling friction coefficient | 0.23 | 0.47 | H | 皮-叶静摩擦系数 Skinlesf static friction coefficient | 0.31 | 0.45 |

| C | 穰-皮静摩擦系数 Straw coreskin static friction coefficient | 0.73 | 1.07 | I | 皮-叶滚动摩擦系数 Skinlesf rolling friction coefficient | 0.29 | 0.45 |

| D | 穰-皮碰撞恢复系数 Straw coreskin collision restitution coefficient | 0.33 | 0.47 | J | 叶-叶静摩擦系数 Lesflesf static friction coefficient | 0.31 | 0.45 |

| E | 穰-叶静摩擦系数 Straw corelesf static friction coefficient | 0.75 | 1.11 | K | 叶-叶碰撞恢复系数 Lesflesf collision restitution coefficient | 0.27 | 0.40 |

| F | 穰-叶滚动摩擦系数 Straw corelesf rolling friction coefficient | 0.25 | 0.42 | ||||

表4 Plackett-Burman试验参数表

Table 4 Plackett-Buman test parameters table

代号 Code | 仿真参数 Simulation parameter | 水平 Level | 代号 Code | 仿真参数 Simulation parameter | 水平 Level | ||

|---|---|---|---|---|---|---|---|

| -1 | +1 | -1 | +1 | ||||

| A | 穰-穰静摩擦系数 Straw corestraw core static friction coefficient | 2.14 | 3.27 | G | 皮-皮静摩擦系数 Skinskin static friction coefficient | 0.58 | 0.75 |

| B | 穰-穰滚动摩擦系数 Straw corestraw core rolling friction coefficient | 0.23 | 0.47 | H | 皮-叶静摩擦系数 Skinlesf static friction coefficient | 0.31 | 0.45 |

| C | 穰-皮静摩擦系数 Straw coreskin static friction coefficient | 0.73 | 1.07 | I | 皮-叶滚动摩擦系数 Skinlesf rolling friction coefficient | 0.29 | 0.45 |

| D | 穰-皮碰撞恢复系数 Straw coreskin collision restitution coefficient | 0.33 | 0.47 | J | 叶-叶静摩擦系数 Lesflesf static friction coefficient | 0.31 | 0.45 |

| E | 穰-叶静摩擦系数 Straw corelesf static friction coefficient | 0.75 | 1.11 | K | 叶-叶碰撞恢复系数 Lesflesf collision restitution coefficient | 0.27 | 0.40 |

| F | 穰-叶滚动摩擦系数 Straw corelesf rolling friction coefficient | 0.25 | 0.42 | ||||

序号 No. | A | B | C | D | E | F | G | H | I | J | K | 堆积角 Stacking angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 34.03 |

| 2 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 32.21 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 31.76 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 25.26 |

| 5 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 33.59 |

| 6 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 35.07 |

| 7 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 34.07 |

| 8 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 26.39 |

| 9 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 27.17 |

| 10 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 32.22 |

| 11 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 28.77 |

| 12 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 27.16 |

表5 Plackett-Burman试验设计及结果

Table 5 Plackett-Burman trial design and results

序号 No. | A | B | C | D | E | F | G | H | I | J | K | 堆积角 Stacking angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 34.03 |

| 2 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 32.21 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 31.76 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 25.26 |

| 5 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 33.59 |

| 6 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 35.07 |

| 7 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 34.07 |

| 8 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 26.39 |

| 9 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 27.17 |

| 10 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 32.22 |

| 11 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 28.77 |

| 12 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 27.16 |

参数 Parameter | 调整后的偏差平方和 Adjusted sum of squared deviations | F值 F value | P值 P value |

|---|---|---|---|

| A | 0.92 | 8.79 | 0.207 1 |

| B | 14.39 | 137.64 | 0.054 1 |

| C | 1.17 | 11.15 | 0.185 2 |

| D | 3.54 | 33.89 | 0.108 3 |

| E | 5.55 | 53.08 | 0.086 8 |

| F | 28.21 | 269.90* | 0.038 7 |

| G | 0.95 | 9.11 | 0.203 7 |

| H | 4.86 | 47.56 | 0.162 7 |

| I | 19.25 | 184.18* | 0.046 8 |

| J | 50.43 | 482.43* | 0.029 0 |

| K | 7.94 | 75.94 | 0.072 7 |

表6 Plackett-Burman试验结果方差分析

Table 6 Variance analysis of Plackett-Burman test results

参数 Parameter | 调整后的偏差平方和 Adjusted sum of squared deviations | F值 F value | P值 P value |

|---|---|---|---|

| A | 0.92 | 8.79 | 0.207 1 |

| B | 14.39 | 137.64 | 0.054 1 |

| C | 1.17 | 11.15 | 0.185 2 |

| D | 3.54 | 33.89 | 0.108 3 |

| E | 5.55 | 53.08 | 0.086 8 |

| F | 28.21 | 269.90* | 0.038 7 |

| G | 0.95 | 9.11 | 0.203 7 |

| H | 4.86 | 47.56 | 0.162 7 |

| I | 19.25 | 184.18* | 0.046 8 |

| J | 50.43 | 482.43* | 0.029 0 |

| K | 7.94 | 75.94 | 0.072 7 |

| 序号No. | 穰-叶滚动摩擦系数 Straw coreleaf rolling friction coefficient | 皮-叶滚动摩擦系数 Skinleaf rolling friction coefficient | 叶-叶静摩擦系数 Leavesleaf static friction coefficient | 堆积角 Stacking angle/(°) | 相对误差 Relative error |

|---|---|---|---|---|---|

| 1 | 0.25 | 0.29 | 0.31 | 27.65 | 9.05 |

| 2 | 0.29 | 0.33 | 0.35 | 28.07 | 7.66 |

| 3 | 0.33 | 0.37 | 0.38 | 31.16 | 2.50 |

| 4 | 0.38 | 0.41 | 0.42 | 32.57 | 7.14 |

| 5 | 0.42 | 0.45 | 0.45 | 34.50 | 13.49 |

表7 最陡爬坡试验设计及结果

Table 7 Design and results of steepest climbing test

| 序号No. | 穰-叶滚动摩擦系数 Straw coreleaf rolling friction coefficient | 皮-叶滚动摩擦系数 Skinleaf rolling friction coefficient | 叶-叶静摩擦系数 Leavesleaf static friction coefficient | 堆积角 Stacking angle/(°) | 相对误差 Relative error |

|---|---|---|---|---|---|

| 1 | 0.25 | 0.29 | 0.31 | 27.65 | 9.05 |

| 2 | 0.29 | 0.33 | 0.35 | 28.07 | 7.66 |

| 3 | 0.33 | 0.37 | 0.38 | 31.16 | 2.50 |

| 4 | 0.38 | 0.41 | 0.42 | 32.57 | 7.14 |

| 5 | 0.42 | 0.45 | 0.45 | 34.50 | 13.49 |

| 水平Level | F | I | J |

|---|---|---|---|

| -1 | 0.29 | 0.33 | 0.35 |

| 0 | 0.33 | 0.37 | 0.38 |

| 1 | 0.38 | 0.41 | 0.42 |

表8 显著接触参数水平

Table 8 Significant exposure parameter levels

| 水平Level | F | I | J |

|---|---|---|---|

| -1 | 0.29 | 0.33 | 0.35 |

| 0 | 0.33 | 0.37 | 0.38 |

| 1 | 0.38 | 0.41 | 0.42 |

| 序号No. | F | I | J | 堆积角 Stacking angle/(°) |

|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 26.43 |

| 2 | 1 | -1 | 0 | 30.16 |

| 3 | -1 | 1 | 0 | 30.24 |

| 4 | 1 | 1 | 0 | 34.78 |

| 5 | -1 | 0 | -1 | 27.56 |

| 6 | 1 | 0 | -1 | 32.40 |

| 7 | -1 | 0 | 1 | 28.41 |

| 8 | 1 | 0 | 1 | 33.64 |

| 9 | 0 | -1 | -1 | 27.49 |

| 10 | 0 | 1 | -1 | 31.94 |

| 11 | 0 | -1 | 1 | 28.43 |

| 12 | 0 | 1 | 1 | 32.10 |

| 13 | 0 | 0 | 0 | 30.04 |

| 14 | 0 | 0 | 0 | 30.33 |

| 15 | 0 | 0 | 0 | 30.46 |

| 16 | 0 | 0 | 0 | 29.34 |

| 17 | 0 | 0 | 0 | 29.17 |

表9 Box-Behnken 试验设计及结果

Table 9 Box-Behnken trial design and results

| 序号No. | F | I | J | 堆积角 Stacking angle/(°) |

|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 26.43 |

| 2 | 1 | -1 | 0 | 30.16 |

| 3 | -1 | 1 | 0 | 30.24 |

| 4 | 1 | 1 | 0 | 34.78 |

| 5 | -1 | 0 | -1 | 27.56 |

| 6 | 1 | 0 | -1 | 32.40 |

| 7 | -1 | 0 | 1 | 28.41 |

| 8 | 1 | 0 | 1 | 33.64 |

| 9 | 0 | -1 | -1 | 27.49 |

| 10 | 0 | 1 | -1 | 31.94 |

| 11 | 0 | -1 | 1 | 28.43 |

| 12 | 0 | 1 | 1 | 32.10 |

| 13 | 0 | 0 | 0 | 30.04 |

| 14 | 0 | 0 | 0 | 30.33 |

| 15 | 0 | 0 | 0 | 30.46 |

| 16 | 0 | 0 | 0 | 29.34 |

| 17 | 0 | 0 | 0 | 29.17 |

方差来源 Source of variation | 平方和 Sum of Squares | 自由度 df | 均方 Mean Square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 79.150 0 | 9 | 8.790 0 | 32.420 0 | < 0.000 1 |

| F | 42.040 0 | 1 | 42.040 0 | 154.980 0 | < 0.000 1 |

| I | 34.240 0 | 1 | 34.240 0 | 126.210 0 | < 0.000 1 |

| J | 1.270 0 | 1 | 1.270 0 | 4.690 0 | 0.067 1 |

| FI | 0.164 0 | 1 | 0.164 0 | 0.604 6 | 0.462 3 |

| FJ | 0.038 0 | 1 | 0.038 0 | 0.140 2 | 0.719 2 |

| IJ | 0.152 1 | 1 | 0.152 1 | 0.560 7 | 0.478 4 |

| F² | 1.150 0 | 1 | 1.150 0 | 4.250 0 | 0.078 1 |

| I² | 0.000 5 | 1 | 0.000 5 | 0.001 9 | 0.966 6 |

| J² | 0.051 9 | 1 | 0.051 9 | 0.191 2 | 0.675 1 |

| 残差Residual | 1.900 0 | 7 | 0.271 3 | ||

| 失拟项Lack of fit | 0.539 5 | 3 | 0.179 8 | 0.529 1 | 0.685 9 |

| 纯误差Pure error | 1.360 0 | 4 | 0.339 9 | ||

| 总和Cor total | 81.050 0 | 16 |

表10 Box-Behnken 试验回归模型方差分析

Table 10 Variation analysis of Box-Behnken design quadratic model

方差来源 Source of variation | 平方和 Sum of Squares | 自由度 df | 均方 Mean Square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 79.150 0 | 9 | 8.790 0 | 32.420 0 | < 0.000 1 |

| F | 42.040 0 | 1 | 42.040 0 | 154.980 0 | < 0.000 1 |

| I | 34.240 0 | 1 | 34.240 0 | 126.210 0 | < 0.000 1 |

| J | 1.270 0 | 1 | 1.270 0 | 4.690 0 | 0.067 1 |

| FI | 0.164 0 | 1 | 0.164 0 | 0.604 6 | 0.462 3 |

| FJ | 0.038 0 | 1 | 0.038 0 | 0.140 2 | 0.719 2 |

| IJ | 0.152 1 | 1 | 0.152 1 | 0.560 7 | 0.478 4 |

| F² | 1.150 0 | 1 | 1.150 0 | 4.250 0 | 0.078 1 |

| I² | 0.000 5 | 1 | 0.000 5 | 0.001 9 | 0.966 6 |

| J² | 0.051 9 | 1 | 0.051 9 | 0.191 2 | 0.675 1 |

| 残差Residual | 1.900 0 | 7 | 0.271 3 | ||

| 失拟项Lack of fit | 0.539 5 | 3 | 0.179 8 | 0.529 1 | 0.685 9 |

| 纯误差Pure error | 1.360 0 | 4 | 0.339 9 | ||

| 总和Cor total | 81.050 0 | 16 |

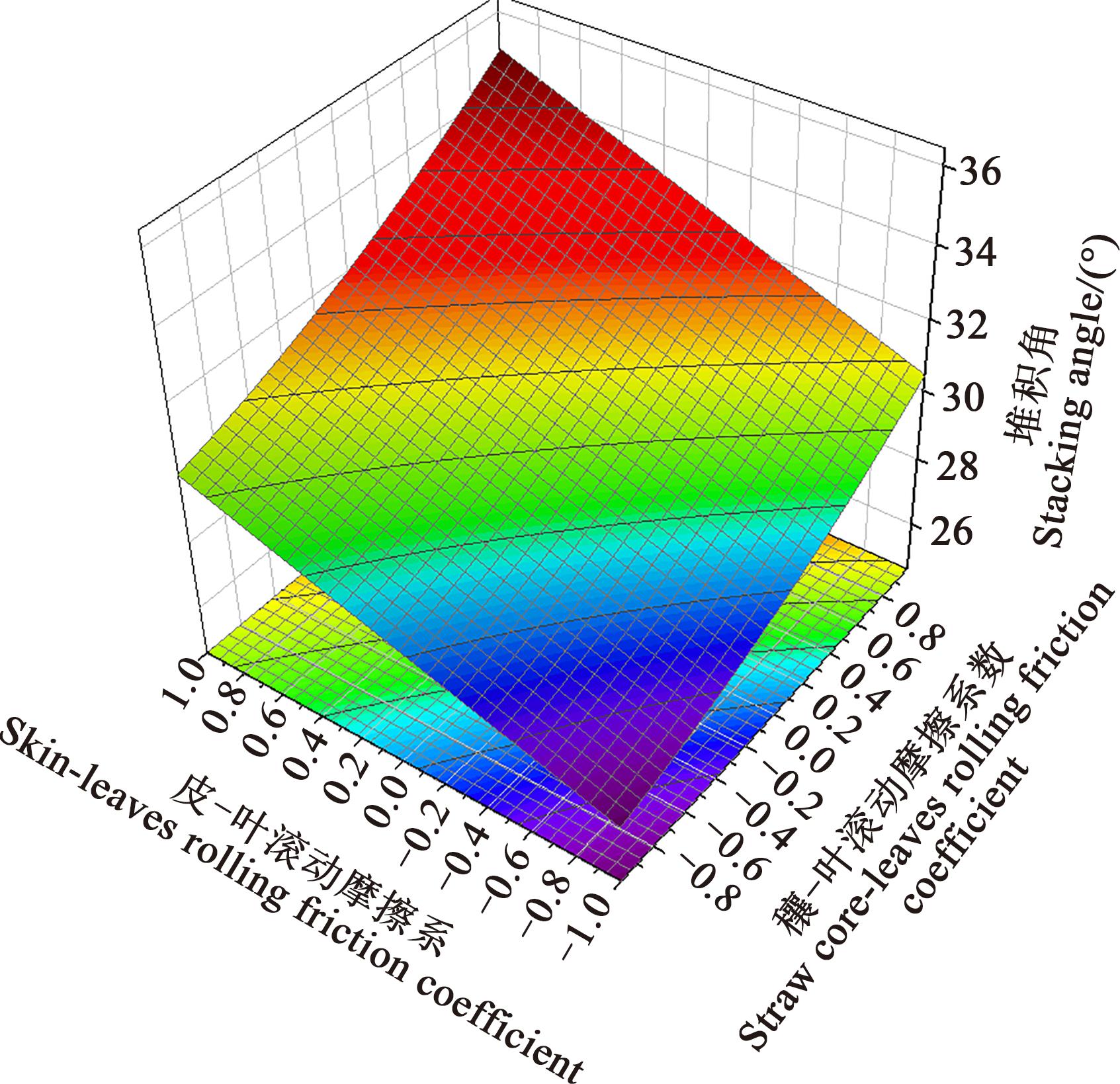

图8 叶-穰滚动摩擦系数、皮-叶滚动摩擦系数对堆积角的影响曲面图

Fig. 8 Surface diagram of the influence of straw core - leaves rolling friction coefficient and skin - leaves rolling friction coefficient on stacking angle

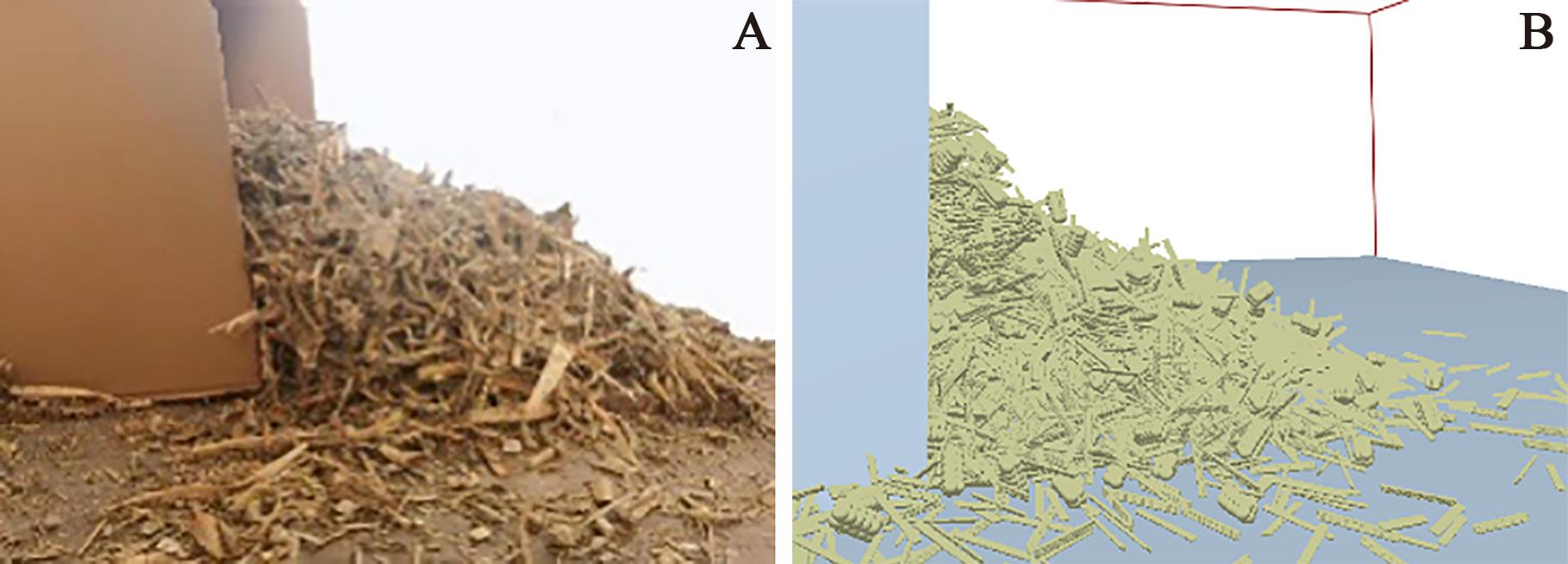

图9 揉碎玉米秸秆堆积角物理试验和仿真对比A:物理试验;B:仿真试验

Fig. 9 Physical test and simulation comparison of the accumulation angle of crushed corn stalksA: Physical experiment; B: Simulation test

| 参数 Parameter | 数值Value | 参数 Parameter | 数值Value |

|---|---|---|---|

穰-穰静摩擦系数 Straw corestraw core static friction coefficient | 2.705 | 皮-皮碰撞恢复系数 Skin-skin collision restitution coefficient | 0.380 |

穰-穰滚动摩擦系数 Straw corestraw core rolling friction coefficient | 0.350 | 皮-叶静摩擦系数 Skinleaf static friction coefficient | 0.380 |

穰-穰碰撞恢复系数 Straw corestraw core collision restitution coefficient | 0.390 | 皮-叶滚动摩擦系 Skinleaf rolling friction coefficient | 0.377 |

穰-皮静摩擦系数 Straw coreskin static friction coefficient | 0.900 | 皮-叶碰撞恢复系数 Skinleaf collision restitution coefficient | 0.385 |

穰-皮滚动摩擦系数 Straw coreskin rolling friction coefficient | 0.345 | 皮-45钢静摩擦系数 Skin45 steel static friction coefficient | 0.325 |

穰-皮碰撞恢复系数 Straw coreskin collision restitution coefficient | 0.400 | 皮-45钢滚动摩擦系数 Skin45 steel rolling friction coefficient | 0.270 |

穰-叶静摩擦系数 Straw coreleaf static friction coefficient | 0.930 | 皮-45钢碰撞恢复系数 Skin45 steel collision restitution coefficient | 0.425 |

穰-叶滚动摩擦系数 Straw coreleaf rolling friction coefficient | 0.325 | 叶-叶静摩擦系数 Leafleaf static friction coefficient | 0.411 |

穰-叶碰撞恢复系数 Straw coreleaf collision restitution coefficient | 0.395 | 叶-叶滚动摩擦系数 Leafleaf rolling friction coefficient | 0.335 |

穰-45钢静摩擦系数 Straw core45 steel static friction coefficient | 1.030 | 叶-叶碰撞恢复系数 Leafleaf collision restitution coefficient | 0.335 |

穰-45钢滚动摩擦系数 Straw core45 steel rolling friction coefficient | 0.365 | 叶-45钢静摩擦系数 Leaf45 steel static friction coefficient | 0.380 |

穰-45钢碰撞恢复系数 Straw core45 steel collision restitution coefficient | 0.415 | 叶-45钢滚动摩擦系数 Leaf45 steel rolling friction coefficient | 0.215 |

皮-皮静摩擦系数 Skinskin static friction coefficient | 0.665 | 叶-45钢碰撞恢复系数 Leaf45 steel collision restitution coefficient | 0.395 |

皮-皮滚动摩擦系数 Skin- skin rolling friction coefficient | 0.295 |

表11 最终参数确定

Table 11 Final parameter determination

| 参数 Parameter | 数值Value | 参数 Parameter | 数值Value |

|---|---|---|---|

穰-穰静摩擦系数 Straw corestraw core static friction coefficient | 2.705 | 皮-皮碰撞恢复系数 Skin-skin collision restitution coefficient | 0.380 |

穰-穰滚动摩擦系数 Straw corestraw core rolling friction coefficient | 0.350 | 皮-叶静摩擦系数 Skinleaf static friction coefficient | 0.380 |

穰-穰碰撞恢复系数 Straw corestraw core collision restitution coefficient | 0.390 | 皮-叶滚动摩擦系 Skinleaf rolling friction coefficient | 0.377 |

穰-皮静摩擦系数 Straw coreskin static friction coefficient | 0.900 | 皮-叶碰撞恢复系数 Skinleaf collision restitution coefficient | 0.385 |

穰-皮滚动摩擦系数 Straw coreskin rolling friction coefficient | 0.345 | 皮-45钢静摩擦系数 Skin45 steel static friction coefficient | 0.325 |

穰-皮碰撞恢复系数 Straw coreskin collision restitution coefficient | 0.400 | 皮-45钢滚动摩擦系数 Skin45 steel rolling friction coefficient | 0.270 |

穰-叶静摩擦系数 Straw coreleaf static friction coefficient | 0.930 | 皮-45钢碰撞恢复系数 Skin45 steel collision restitution coefficient | 0.425 |

穰-叶滚动摩擦系数 Straw coreleaf rolling friction coefficient | 0.325 | 叶-叶静摩擦系数 Leafleaf static friction coefficient | 0.411 |

穰-叶碰撞恢复系数 Straw coreleaf collision restitution coefficient | 0.395 | 叶-叶滚动摩擦系数 Leafleaf rolling friction coefficient | 0.335 |

穰-45钢静摩擦系数 Straw core45 steel static friction coefficient | 1.030 | 叶-叶碰撞恢复系数 Leafleaf collision restitution coefficient | 0.335 |

穰-45钢滚动摩擦系数 Straw core45 steel rolling friction coefficient | 0.365 | 叶-45钢静摩擦系数 Leaf45 steel static friction coefficient | 0.380 |

穰-45钢碰撞恢复系数 Straw core45 steel collision restitution coefficient | 0.415 | 叶-45钢滚动摩擦系数 Leaf45 steel rolling friction coefficient | 0.215 |

皮-皮静摩擦系数 Skinskin static friction coefficient | 0.665 | 叶-45钢碰撞恢复系数 Leaf45 steel collision restitution coefficient | 0.395 |

皮-皮滚动摩擦系数 Skin- skin rolling friction coefficient | 0.295 |

| 1 | 周腰华,周洋,赖晓璐,等.玉米秸秆综合利用技术模式研究[J].玉米科学, 2019,27(6):186-190. |

| ZHOU Y H, ZHOU Y, LAI X L, et al.. Research on the technology model of comprehensive utilization of corn stalk [J]. Corn Sci., 2019, 27(6):186-190. | |

| 2 | 赵福迪,魏思明,黄文明.玉米秸秆机械化利用情况与发展途径分析[J].农机使用与维修, 2019(7):48-48. |

| 3 | 乌兰图雅,青林,王春光.揉碎玉米秸秆螺旋-气力耦合输送装置设计[J].农业工程学报, 2019,35(6):29-38. |

| WULANTUYA, QING L, WANG C G. Design of screw-pneumatic coupling conveying device for crushing corn stalks [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(6):29-38. | |

| 4 | DHEERAJ M, ABHISHEK S, HARSH P, et al.. A review of granular flow in screw feeders and conveyors [J]. Powder Technol., 2020, 366:369-381. |

| 5 | 扈伟昊,杨发展,赵国栋,等.基于离散元法的立式旋耕刀工作参数分析与优化[J].中国农机化学报, 2022,43(10):25-32, 41. |

| HU W H, YANG F Z, ZHAO G D, et al.. Analysis and optimization of working parameters of vertical rotary blade based on discrete element method [J]. China J. Agric. Mach. Chem., 2022, 43(10):25-32, 41 | |

| 6 | 刘元义,于圣洁,胥备,等.基于离散元的设施农业就地翻土犁的研究与试验[J/OL].吉林大学学报(工学版),2022 [2022-10-09]. . |

| LIU Y Y, YU S J, XU B, et al. Research and test of on-site plow for facility agriculture based on discrete element [J/OL]. J. Jilin Univ. (Eng.), 2022 [2022-10-09]. . | |

| 7 | 李修银,廖敏,杨杰,等.羌活籽粒和珍珠岩的离散元参数标定及排种验证[J].中国农机化学报, 2022,43(8):40-46. |

| LI X Y, LIAO M, YANG J, et al.. Discrete element parameter calibration and seed metering verification of Qianghuo grain and perlite [J]. China J. Agric. Mach. Chem., 2022, 43 (8):40-46. | |

| 8 | 陈晨,马学东,刘飞宇,等.偏心摆振下圆簸箕中谷物分离的离散元模拟研究[J].农机化研究,2023,45(5):13-19. |

| CHEN C, MA X D, LIU F Y, et al.. Discrete element simulation study on grain separation in circular dustpan under eccentric sway [J]. Res. Agric. Mech., 2023, 45(5):13-19. | |

| 9 | 季雨.基于CFD-DEM螺旋输送机内颗粒流动特性数值模拟研究[D].大庆:东北石油大学, 2020. |

| JI Y. Numerical simulation of particle flow characteristics in screw conveyor based on CFD-DEM [D]. Daqing: Northeast Petroleum University, 2020. | |

| 10 | 宁廷州,李偎,缑亚楠.基于EDEM的倾斜螺旋输送机输送能力研究[J].牡丹江师范学院学报(自然科学版),2019(4):38-41. |

| NING T Z, LI C, JIN Y N. Research on conveying capacity of inclined screw conveyor based on EDEM [J]. J. Mudanjiang Norm. Univ. (Nat. Sci.), 2019(4):38-41. | |

| 11 | 张胜伟,张瑞雨,陈天佑,等.绿豆种子离散元仿真参数标定与排种试验[J].农业机械学报, 2022, 53(3):71-79. |

| ZHANG S W, ZHANG R Y, CHEN T Y, et al.. The discrete element simulation parameter calibration and seeding test of mung bean seeds [J]. J. Agric. Mach., 2022, 53(3):71-79. | |

| 12 | 丁文波,朱继平,陈伟,等.基于的青稞接触参数仿真标定[J].中国农机化学报,2021,42(9):114-121. |

| DING W B, ZHU J P, CHEN W, et al.. Simulation calibration of contact parameters of highland barley based on EDEM [J]. Chin. J. Agric. Mach., 2021, 42(9):114-121. | |

| 13 | 赵吉坤,宋武斌,李晶晶.基于的水稻秸秆建模及力学性能分析[J].土壤通报,2020,51(5):1086-1093. |

| ZHAO J K, SONG W B, LI J J. Modeling and mechanical properties analysis of rice straw based on EDEM [J]. Soil Bull., 2020, 51(5):1086-1093. | |

| 14 | 康宏彬,刘铭,王雷,等.基于的马铃薯收获机分离输送装置仿真分析[J].农机化研究,2022,44(5):1-8. |

| KANG H B, LIU M, WANG L, et al.. Simulation analysis of separation and conveying device of potato harvester based on EDEM [J]. Res. Agric. Mech., 2022, 44(5):1-8. | |

| 15 | 刘瑞,李衍军,刘忠军,等.包衣玉米种子离散元参数分析与标定[J].农业机械学报,2021,52(S1):1-8. |

| LIU R, LI Y J, LIU Z J, et al.. Discrete element parameter analysis and calibration of coated corn seeds [J]. J. Agric. Mach., 2021, 52(S1):1-8. | |

| 16 | 马彦华,宋春东,宣传忠,等.苜蓿秸秆压缩仿真离散元模型参数标定[J].农业工程学报,2020,36(11):22-30. |

| MA Y H, SONG C D, XUAN C Z, et al.. Parameter calibration of discrete element model for alfalfa straw compression simulation [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(11):22-30. | |

| 17 | 张涛,刘飞,赵满全,等.玉米秸秆接触物理参数测定与离散元仿真标定[J].中国农业大学学报,2018,23(4):120-127. |

| ZHANG T, LIU F, ZHAO M Q, et al.. Measurement of contact physical parameters of corn stalks and discrete element simulation calibration [J]. J. China Agric. Univ., 2018, 23(4):120-120. | |

| 18 | 赖庆辉,袁海阔,胡子武,等.三七种苗物料特性研究及离散元法参数标定[J].扬州大学学报(农业与生命科学版), 2018,39(2):74-79. |

| LAI Q H, YUAN H K, HU Z W, et al.. Study on material properties of Panax notoginseng seedlings and parameter calibration by discrete element method [J]. J. Yangzhou Univ. (Agric. Life Sci.), 2018, 39(2):74-79. | |

| 19 | 中华人民共和国国家卫生和计划生育委员会. 食品安全国家标准食品中水分的测定: . [S].北京:中国标准出版社, 2016. |

| 20 | 于克强.转轮式全混合日粮混合机混合机理分析及试验研究[D].吉林:东北农业大学, 2015. |

| YU K Q. Mixing mechanism analysis and experimental research of rotary total mixed ration mixer [D]. Jilin: Northeast Agricultural University, 2015. | |

| 21 | ZHOU L, YU J Q, LIANG L S, et al.. DEM parameter calibration of maize seeds and the effect of rolling friction [J]. Processes, 2021, 9(6):914-914. |

| 22 | 胡广锐,卜令昕,张恩宇,等.苹果两向异性力学特性和跌落试验研究[J].农机化研究, 2021, 43(4):154-160. |

| HU G R, BU L X, ZHANG E Y, et al.. Study on anisotropic mechanical properties and drop test of apples [J]. Res. Agric. Mech., 2021, 43(4):154-160. | |

| 23 | WANG X W, MA H Z, LI B, et al.. Review on the research of contact parameters calibration of particle system [J]. J. Mech. Sci. Technol., 2022, 36:1-1. |

| 24 | 贾富国,韩燕龙,刘扬,等.稻谷颗粒物料堆积角模拟预测方法[J].农业工程学报, 2014, 30(11):254-260. |

| JIA F G, HAN Y L, LIU Y, et al.. Simulation and prediction method of accumulation angle of rice granular materials [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(11):254-260. | |

| 25 | 张锋伟,宋学锋,张雪坤 等.玉米秸秆揉丝破碎过程力学特性仿真与试验[J].农业工程学报,2019,35(9):58-65. |

| ZHANG F W, SONG X F, ZHANG X K, et al. Simulation and test of mechanical properties in the process of corn straw kneading and crushing [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(9):58-65 |

| [1] | 张海东, 唐志贤, 张立芸, 于淇, 宋朝君. 基于GA-BP-GA优化林下三七种植红壤离散元仿真参数[J]. 中国农业科技导报, 2025, 27(9): 120-130. |

| [2] | 奚小波, 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏. 一种果园中耕避障除草机的设计与试验[J]. 中国农业科技导报, 2025, 27(7): 101-110. |

| [3] | 许静, 李晗, 陈平录, 罗江旎, 唐承露, 刘木华. 油茶茶枯离散元模型参数标定与试验[J]. 中国农业科技导报, 2025, 27(3): 112-121. |

| [4] | 冯长龙, 黄春光, 宁辰阳, 李树平, 陈科锦. 植树机挖坑机构螺旋式钻头性能特性优化研究[J]. 中国农业科技导报, 2025, 27(2): 89-98. |

| [5] | 田祥州, 贺福强, 陈发江, 詹璐歆. 基于休止角标定不同含水率木粉离散元参数[J]. 中国农业科技导报, 2025, 27(1): 118-128. |

| [6] | 顿国强, 王雷, 纪欣鑫, 姜新波, 赵宇, 郭娜. 金乡紫皮蒜种离散元参数标定与试验验证[J]. 中国农业科技导报, 2024, 26(8): 131-139. |

| [7] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [8] | 李明, 董帅, 庞永强, 燕洁华, 叶汪忠. 风沙土混拌刀具的改良设计与试验[J]. 中国农业科技导报, 2024, 26(4): 87-96. |

| [9] | 黄元昊, 全腊珍, 胡广发, 全伟, 石方刚. 多种材料与不同含水率土壤的离散元接触参数标定[J]. 中国农业科技导报, 2024, 26(3): 98-109. |

| [10] | 陈林, 余南辉, 王立宗, 范吉军, 雷港, 刘晓鹏, 周龙, 周劲. 米糠和碎米的接触参数测量与离散元仿真标定[J]. 中国农业科技导报, 2024, 26(2): 127-136. |

| [11] | 杨大芳, 李飞翔, 葛越锋, 李奕辰. 基于离散元法的外槽轮排肥器排肥性能研究[J]. 中国农业科技导报, 2024, 26(12): 88-97. |

| [12] | 于淼, 周海宾, 丁京涛, 程红胜, 沈玉君, 范盛远, 张曦, 王健, 徐鹏翔, 程琼仪. 基于EDEM的餐厨垃圾组成颗粒间接触参数标定[J]. 中国农业科技导报, 2023, 25(12): 111-120. |

| [13] | 马紫涛, 赵智豪, 全伟, 石方刚, 高晨, 吴明亮. 基于EDEM的水稻残茬秸秆离散元仿真参数标定[J]. 中国农业科技导报, 2023, 25(11): 103-113. |

| [14] | 单发科, 康朔, 朱建锡, 王永维, 王俊. 基于EDEM的粉垄和旋耕作业混肥效果研究[J]. 中国农业科技导报, 2023, 25(11): 90-102. |

| [15] | 周婷, 孙松林, 朱海英, 彭才望. 含水率对黑水虻生物转化猪粪有机肥黏结流动的影响[J]. 中国农业科技导报, 2023, 25(10): 126-136. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||