Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (1): 129-137.DOI: 10.13304/j.nykjdb.2023.0251

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Qijun TANG1,2,3( ), Xiang XU1,2,3, Kai REN1,2,3, Daqing ZHANG1,2, Ping JIANG1

), Xiang XU1,2,3, Kai REN1,2,3, Daqing ZHANG1,2, Ping JIANG1

Received:2023-04-03

Accepted:2023-06-21

Online:2025-01-15

Published:2025-01-21

唐琦军1,2,3( ), 许祥1,2,3, 任凯1,2,3, 张大庆1,2, 蒋蘋1

), 许祥1,2,3, 任凯1,2,3, 张大庆1,2, 蒋蘋1

作者简介:唐琦军 E-mail:tangqijun293@126.com

基金资助:CLC Number:

Qijun TANG, Xiang XU, Kai REN, Daqing ZHANG, Ping JIANG. Study on Power Consumption Evaluation of Plough Agricultural Machinery in Field Pperation[J]. Journal of Agricultural Science and Technology, 2025, 27(1): 129-137.

唐琦军, 许祥, 任凯, 张大庆, 蒋蘋. 铧式犁农机田间作业过程机具功耗测评研究[J]. 中国农业科技导报, 2025, 27(1): 129-137.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2023.0251

| 参数 Parameter | 数值或类型 Value or type |

|---|---|

| 整机质量Curb weight/kg | 4 155 |

| 整车尺寸(长×宽×高) Overall vehicle size(length×width×hight)/mm | 4 530×2 050×2 810 |

| 轮胎规格(前轮/后轮) Tire size (front/rear) | 11.2-24/16.9-34 |

| 档位数(前进+倒退) Number of gears (forward+reverse) | 16+8 |

| 驱动形式 Drive form | 四轮驱动 Four-wheel drive |

| 柴油机额定功率 Diesel engine rated power/kW | 100 |

| 农机具 Agricultural implement | 五铧犁 Five-share plough |

| 挂接形式 Hook-up form | 三点悬挂 Three-point suspension |

Table 1 Specification of the plough agricultural machinery

| 参数 Parameter | 数值或类型 Value or type |

|---|---|

| 整机质量Curb weight/kg | 4 155 |

| 整车尺寸(长×宽×高) Overall vehicle size(length×width×hight)/mm | 4 530×2 050×2 810 |

| 轮胎规格(前轮/后轮) Tire size (front/rear) | 11.2-24/16.9-34 |

| 档位数(前进+倒退) Number of gears (forward+reverse) | 16+8 |

| 驱动形式 Drive form | 四轮驱动 Four-wheel drive |

| 柴油机额定功率 Diesel engine rated power/kW | 100 |

| 农机具 Agricultural implement | 五铧犁 Five-share plough |

| 挂接形式 Hook-up form | 三点悬挂 Three-point suspension |

| 名称Name | 型号Model | 参数说明Parameter description |

|---|---|---|

| 拉力传感器Tensile force sensor | NOS-C902 | 0~50 kN/0.5% FS |

| GPS仪 GPS instrument | Speedbox-RTK | 0.05 km·h-1 |

| CAN总线分析仪CAN bus analyzer | Kvaser | 波特率Baud rate 40~1 000 kb·s-1 |

| 转速传感器Speed sensor | 霍尔传感器Hall sensor | ±0.1% FS |

| 发动机台架Engine bench | 电涡流测功机 Eddy current dynamometer | 扭矩Torque:±0.5% FS 转速Rotational speed:±0.5 r·min-1 |

Table 2 Main equipment and parameters in the test

| 名称Name | 型号Model | 参数说明Parameter description |

|---|---|---|

| 拉力传感器Tensile force sensor | NOS-C902 | 0~50 kN/0.5% FS |

| GPS仪 GPS instrument | Speedbox-RTK | 0.05 km·h-1 |

| CAN总线分析仪CAN bus analyzer | Kvaser | 波特率Baud rate 40~1 000 kb·s-1 |

| 转速传感器Speed sensor | 霍尔传感器Hall sensor | ±0.1% FS |

| 发动机台架Engine bench | 电涡流测功机 Eddy current dynamometer | 扭矩Torque:±0.5% FS 转速Rotational speed:±0.5 r·min-1 |

| 编号 Number | 变速器档位 Transmission gear | 目标耕作速度 Target tillage speed/(km·h-1) | 耕深 Tillage depth/cm |

|---|---|---|---|

| 1 | 高档,慢速,主变速三档 High, slow, gear Ⅲ | 5.7 | 23 |

| 2 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 7.1 | 23 |

| 3 | 低档,快速,主变速二档 Low, fast, gear Ⅱ | 8.9 | 23 |

| 4 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 20 |

| 5 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 26 |

Table 3 Field experimental scheme for the plough agricultural machinery

| 编号 Number | 变速器档位 Transmission gear | 目标耕作速度 Target tillage speed/(km·h-1) | 耕深 Tillage depth/cm |

|---|---|---|---|

| 1 | 高档,慢速,主变速三档 High, slow, gear Ⅲ | 5.7 | 23 |

| 2 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 7.1 | 23 |

| 3 | 低档,快速,主变速二档 Low, fast, gear Ⅱ | 8.9 | 23 |

| 4 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 20 |

| 5 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 26 |

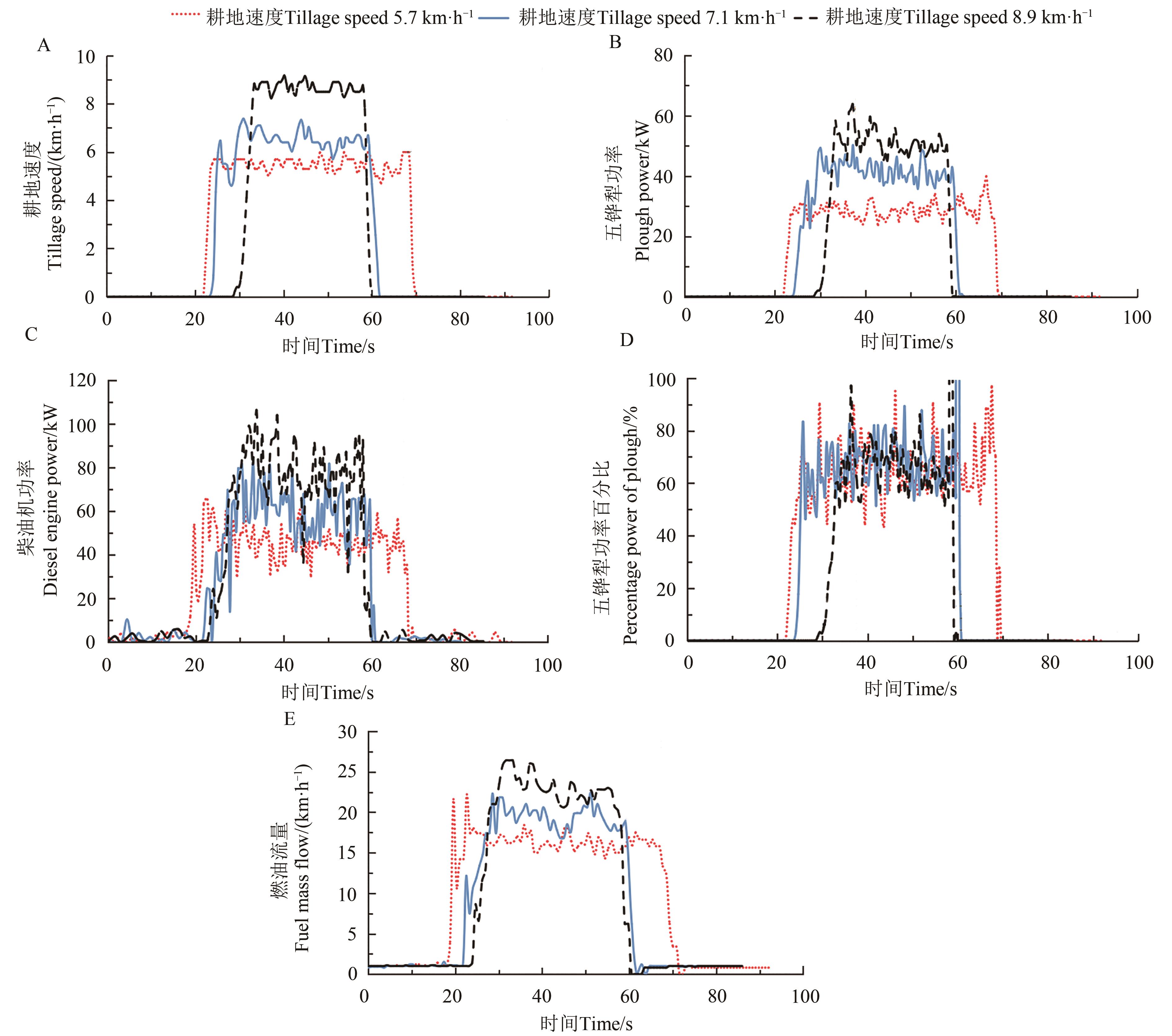

Fig. 3 Test results of different tillage speed of the plough agricultural machineryA:Tillage speed; B:Five-furrow plough power; C:Diesel engine power; D: Five-furrow plough power accounts for the percentage of the diesel engine power; E:Fuel consumption of the plough agricultural machinery

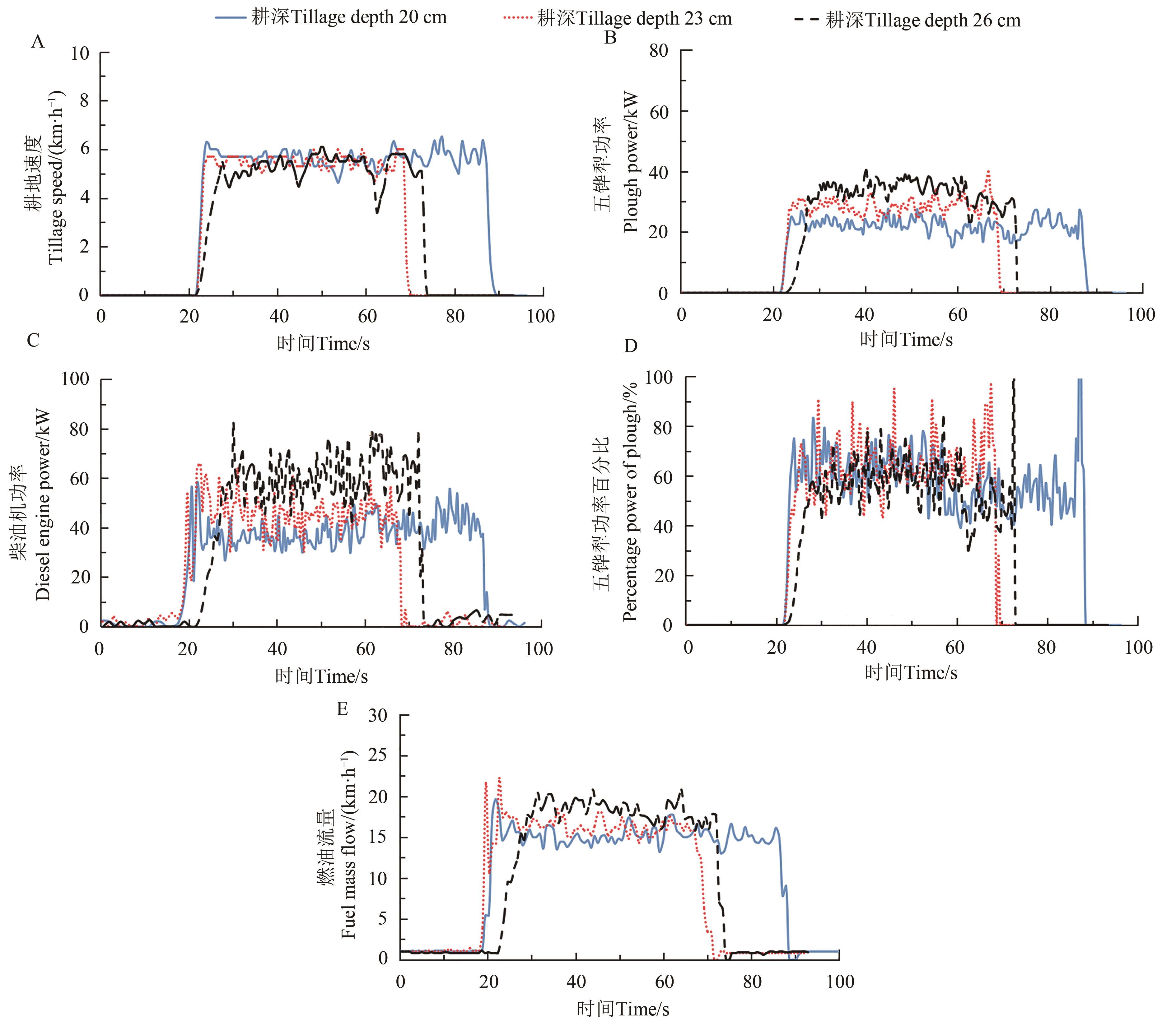

Fig. 4 Test results of different tillage depth of the plough agricultural machineryA:Tillage speed; B:Five-furrow plough power; C:Diesel engine power; D: Five-furrow plough power accounts for the percentage of the diesel engine power; E:Fuel consumption of the plough agricultural machinery

| 编号 Number | 时间 Time/s | 耕地速度 Tillage speed/ (km·h-1) | 铧犁功耗 Plough power/kW | 柴油机功率 Diesel engine power/kW | 铧犁功率比 Plough power ratio/% | 油耗 Fuel mass flow/(kg·h-1) |

|---|---|---|---|---|---|---|

| 1 | 19.61~66.96 | 5.48 | 28.65 | 45.19 | 64.72 | 16.37 |

| 2 | 28.60~59.17 | 6.44 | 40.78 | 59.88 | 67.30 | 19.45 |

| 3 | 31.68~57.43 | 8.69 | 51.44 | 77.52 | 66.10 | 22.97 |

| 4 | 21.03~86.44 | 5.65 | 22.19 | 38.75 | 58.28 | 15.26 |

| 5 | 29.11~71.98 | 5.28 | 33.25 | 60.75 | 56.24 | 18.28 |

Table 4 Average value of the performance parameters of the plough agricultural machinery

| 编号 Number | 时间 Time/s | 耕地速度 Tillage speed/ (km·h-1) | 铧犁功耗 Plough power/kW | 柴油机功率 Diesel engine power/kW | 铧犁功率比 Plough power ratio/% | 油耗 Fuel mass flow/(kg·h-1) |

|---|---|---|---|---|---|---|

| 1 | 19.61~66.96 | 5.48 | 28.65 | 45.19 | 64.72 | 16.37 |

| 2 | 28.60~59.17 | 6.44 | 40.78 | 59.88 | 67.30 | 19.45 |

| 3 | 31.68~57.43 | 8.69 | 51.44 | 77.52 | 66.10 | 22.97 |

| 4 | 21.03~86.44 | 5.65 | 22.19 | 38.75 | 58.28 | 15.26 |

| 5 | 29.11~71.98 | 5.28 | 33.25 | 60.75 | 56.24 | 18.28 |

| 编号 Number | 时间 Time/s | 铧犁功率循环变动率 Coefficient of variation of plough power/% | 柴油机功率循环变动率 Coefficient of variation of diesel engine power/% | 铧犁功率比循环变动率 Coefficient of variation of rate of plough power/% |

|---|---|---|---|---|

| 1 | 19.61~66.96 | 9.57 | 14.18 | 16.47 |

| 2 | 28.60~59.17 | 8.30 | 17.87 | 13.23 |

| 3 | 31.68~57.43 | 8.15 | 17.65 | 13.37 |

| 4 | 21.03~86.44 | 11.59 | 14.04 | 17.16 |

| 5 | 29.11~71.98 | 11.15 | 15.91 | 19.84 |

| 平均值 Average value | 9.75 | 15.93 | 16.01 | |

Table 5 Change rate of the performance parameters of the plough agricultural machinery

| 编号 Number | 时间 Time/s | 铧犁功率循环变动率 Coefficient of variation of plough power/% | 柴油机功率循环变动率 Coefficient of variation of diesel engine power/% | 铧犁功率比循环变动率 Coefficient of variation of rate of plough power/% |

|---|---|---|---|---|

| 1 | 19.61~66.96 | 9.57 | 14.18 | 16.47 |

| 2 | 28.60~59.17 | 8.30 | 17.87 | 13.23 |

| 3 | 31.68~57.43 | 8.15 | 17.65 | 13.37 |

| 4 | 21.03~86.44 | 11.59 | 14.04 | 17.16 |

| 5 | 29.11~71.98 | 11.15 | 15.91 | 19.84 |

| 平均值 Average value | 9.75 | 15.93 | 16.01 | |

| 1 | 邵雪冬, 杨子涵, 宋正河,等. 不同旋耕作业载荷下拖拉机动力输出传动系振动特性分析[J]. 农业机械学报, 2022, 53():332-339. |

| SHAO X D, YANG Z H, SONG Z H, et al.. Analysis of influence of tractor rotary tillage load on power take-off driveline [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(S1):332-339. | |

| 2 | 杨子涵,宋正河,尹宜勇,等.基于POT模型的大功率拖拉机传动轴载荷时域外推方法[J].农业工程学报,2019,35(15):40-47. |

| YANG Z H, SONG Z H, YIN Y Y, et al.. Time domain extrapolation method for load of drive shaft of high-power tractor based on POT model [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(15): 40-47. | |

| 3 | 李淑艳,翟友邦,王小龙,等.基于核密度估计的拖拉机传动轴载荷外推方法[J].中国农业大学学报,2021,26(10):175-184. |

| LI S Y, ZHAI Y B, WANG X L, et al.. An extrapolation method of tractor propeller shaft load based on kernel density estimation [J]. J. China Agric. Univ., 2021,26(10):175-184. | |

| 4 | KIM Y S, KIM W S, BAEK S Y, et al.. Analysis of tillage depth and gear selection for mechanical load and fuel efficiency of an agricultural tractor using an agricultural field measuring system [J/OL]. Sensors, 2020, 20(9): 2450 [2023-03-03]. . |

| 5 | 唐琦军,常宏博,蒋蘋,等.基于转矩模型的柴油机功率在线测试方法研究[J].农业机械学报,2020,51(): 571-578. |

| TANG Q J, CHANG H B, JIANG P, et al.. Online measurement method of diesel engine power based on torque model [J]. Trans. Chin. Soc. Agric. Mach., 2020,51(S2):571-578. | |

| 6 | 陈济勤. 农业机器运用管理学[M]. 第二版. 北京:中国农业出版社, 1997:122-135. |

| 7 | RAJABI-VANDECHALI M, ABBASPOUR-FARD M H, ROHANI A. Development of a prediction model for estimating tractor engine torque based on soft computing and low cost sensors [J]. Measurement, 2018, 121: 83-95. |

| 8 | 刘洪利,王熙. 基于CAN总线的拖拉机机组作业性能分析[J].农业机械学报,2016,47():30-34. |

| LIU H L, WANG X. Analysis of tractor working performace based on CAN bus [J]. Trans. Chin. Soc. Agric. Mach., 2016,47(S1):30-34. | |

| 9 | 翟力欣,姬长英,丁启朔,等.耕作过程中土壤应力场分布的实验研究[J].农机化研究,2014,36(1): 165-169, 173. |

| ZHAI L X, JI C Y, DING Q S, et al.. Stress distribution of soil in the process of soil tillage based on the experiment [J]. J. Agric. Mechan. Res., 2014,36(1):165-169, 173. | |

| 10 | MARI Irshad Ali. 铧式犁作用下的水田土壤三维形变及牵引力研究[D]. 南京: 南京农业大学,2014. |

| MARI I A. Study of three dimensional soil deformation and draught forces on mouldboard plough [D]. Nanjing : Nanjing Agricultural University, 2014. | |

| 11 | SLIMAŘÍK D, SEDLÁK P, DOSTÁL P. Draft sensor loading analysis [J]. Acta Univ. Agric. Et Silviculturae Mendelianae Brunensis, 2014, 62(5): 1103-1108. |

| 12 | KEEN A, GHOLKAR M D, WARD J, et al.. Force measurement between a tractor and a three point linkage mounted cultivation implement [C]// Proceedings of the 10th International Agricultural Engineering Conference. Role of agricultural engineering in advent of changing global landscape. Asian Association for Agricultural Engineering, 2009. |

| 13 | SLIMAŘÍK D, DOSTÁL P, POLCAR A. Static testing of draft sensor for three point hitch dynamometer utilization [J]. Acta Univ. Agric. Et Silviculturae Mendelianae Brunensis, 2015, 63: 835-839. |

| 14 | 王禹,王玲,吕东晓,等.基于FDR阈值自动选取的拖拉机PTO转矩载荷谱外推[J].农业机械学报,2021,52(3):364-372. |

| WANG Y, WANG L, LYU D X, et al.. Extrapolation of tractor PTO torque load spectrum based on automated threshold selection with FDR [J]. Trans. Chin. Soc. Agric. Mach.,2021,52(3):364-372. | |

| 15 | 翟新婷,张晓晨,江柱锦,等.基于混合分布的轮式装载机半轴载荷谱编制[J].农业工程学报,2018,34(8):78-84. |

| ZHAI X T, ZHANG X C, JIANG Z J, et al.. Load spectrum compiling for wheel loader semi-axle based on mixed distribution [J].Trans. Chin. Soc. Agric. Eng., 2018,34(8):78-84. | |

| 16 | 王玲,宗建华,王禹,等.基于最优分布拟合的拖拉机三点悬挂牵引力载荷谱编制与台架试验[J].农业工程学报,2022,38(2):41-49. |

| WANG L, ZONG J H, WANG Y, et al.. Compilation and bench test of traction force load spectrum of tractor three-point hitch based on optimal distribution fitting [J]. Trans. Chin. Soc. Agric. Eng., 2022,38(2):41-49. | |

| 17 | CEROVİĆ V, MILKOVIĆ D, ALEKSANDAR G, et al.. 2D analytical model for evaluation of the forces in the three point hitch mechanism [J]. J. Agric. Sci., 2020, 26(3): 271-281. |

| 18 | CEROVIĆ V, MILKOVIĆ D, GRBOVIĆ A, et al.. Measurement of the stress state in the lower link of the three-point hitch mechanism [M]// Experimental and Numerical Investigations in Materials Science and Engineering. Springer, Cham, 2018: 112-121. |

| 19 | PORTEŠ P, BAUER F, ČUPERA J. Analysis of measured and computed force effects in tractor’s three-point linkage during tillage [C]//18th International Conference Engineering Mechanics 2012, 2012: 1033-1040. |

| 20 | PORTEŠ P, BAUER F, ČUPERA J. Laboratory-experimental verification of calculation of force effects in tractor’s three-point hitch acting on driving wheels [J]. Soil Tillage Res., 2013, 128: 81-90. |

| 21 | JEON H H, JUNG Y J, SIDDIQUE M A A, et al.. Development and validation of simulation model for three point-hitch during agricultural operation [C]//2019 ASABE Annual International Meeting. American Society of Agricultural and Biological Engineers, 2019. |

| 22 | 康云友, 张道林, 鹿秀凤,等. 玉米籽粒机械化直收技术与机具试验研究[J]. 农机化研究, 2019, 41(4):176-181. |

| KANG Y Y, ZHANG D L, LU X F, et al.. Experimental study on mechanized directly harvesting technology and mechinery for corn grain [J]. J. Agric. Mechan. Res., 2019, 41(4):176-181. | |

| 23 | 刘明勇,胡成龙,谢柏林. 基于离散元法的铧式犁仿真优化分析及试验[J]. 浙江农业学报,2022,34(11):2542-2552. |

| LIU M Y, HU C L, XIE B L. Simulation and optimization analysis and experiment of split plough based on discrete ele-ment method [J]. Acta Agric. Zhejiangensis, 2022,34(11):2542-2552. | |

| 24 | 张启森. 拖拉机驱动系统对其性能和油耗的影响及试验研究[J]. 农机化研究,2024,46(2):249-254, 259. |

| ZHANG Q S. Effect of tractor drive system on its performance and fuel consumption and experimental study [J]. J. Agric. Mechan. Res., 2024,46(2):249-254, 259. |

| [1] | Yanfang WANG, Ruixue ZHAO. Bidirectional Empowerment Mechanism of “Data+AI” and Practical Path in Agriculture [J]. Journal of Agricultural Science and Technology, 2025, 27(9): 11-20. |

| [2] | Jianwei WU, Lin ZHANG, Wengang ZHENG, Xiangyang QIN, Zhonggao WU, Xihong FANG, Yongquan WANG, Tiangang LU, Jian WANG, Xiangshu PIAO, Fang WANG, Qiaoyun YUE, Haihe ZHANG, Jing JI, Xiaoman CONG, Qifeng LI. Research Progress on Key Application Scenario of Intelligent Orchard [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 12-23. |

| [3] | Zizhong SHI, Xiangdong HU. Theoretical Logic and Strategic Path of Accelerating the Construction of Livestock Powerhouse [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 1-12. |

| [4] | Wenzhong GAO, Yi ZHANG. Operational Optimization of CCHP Systems on Deep Reinforcement Learning Under Influence of Demand Charge [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 100-109. |

| [5] | Ruiting JIA, Limin YUAN, Zhongju MENG. Effects of Plant Measures on Soil Improvement of Desert Photovoltaic Power Station [J]. Journal of Agricultural Science and Technology, 2023, 25(10): 182-188. |

| [6] | Yu WANG, Ling WANG, Jianhua ZONG, Dongxiao LYU, Shumao WANG. Design and Experiment of Dynamic Loading Bench for Tractor [J]. Journal of Agricultural Science and Technology, 2022, 24(1): 91-97. |

| [7] | LI Siqingaowa, WANG Chunguang, DU Haifeng, JIN Eerdumutu. Research on Cutting Performance of Convex Arc Blade [J]. Journal of Agricultural Science and Technology, 2021, 23(12): 94-100. |

| [8] | LIU Yu, LIU Yuping, ZHANG Tuo. Load Analysis of Rotary Cutter Shaft for Power Tiller Based on DEM and MBD Theory [J]. Journal of Agricultural Science and Technology, 2020, 22(11): 79-86. |

| [9] | ZHOU Zhijiang1,2, CHEN Mingliang2, YANG Peijuan2. Establishment and Optimization of Tissue Culture System for Nandina domestica ‘Fire power’ [J]. Journal of Agricultural Science and Technology, 2019, 21(1): 164-168. |

| [10] | CHEN Xiaodong, CHU Qingquan*. Research on Planning of Ecological Agricultural Park PV-Powered Based on Health-oriented Agriculture [J]. Journal of Agricultural Science and Technology, 2017, 19(10): 45-51. |

| [11] | YANG Yan-tao, QIN Fu*. Estimation of International Market Pricing Power and Countermeasure Research on China's Corn Import [J]. Journal of Agricultural Science and Technology, 2016, 18(3): 195-200. |

| [12] | WEI Xun1, MA Zhong2, JIA Jing-dun1, JIN Shu-qin3. Comparative Studies on Comprehensive Economic Cost of Wood-based Biomass-fired and Coal-fired Cogeneration Plant [J]. , 2012, 14(1): 122-130. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号