Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (6): 123-132.DOI: 10.13304/j.nykjdb.2021.0783

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Shisheng SONG( ), Songlin SUN, Qin FANG, Caiwang PENG(

), Songlin SUN, Qin FANG, Caiwang PENG( ), Ting ZHOU, Haiying ZHU

), Ting ZHOU, Haiying ZHU

Received:2021-09-06

Accepted:2022-03-08

Online:2022-06-15

Published:2022-06-21

Contact:

Caiwang PENG

宋世圣( ), 孙松林, 方芹, 彭才望(

), 孙松林, 方芹, 彭才望( ), 周婷, 朱海英

), 周婷, 朱海英

通讯作者:

彭才望

作者简介:宋世圣 E-mail:hunausss@163.com;

基金资助:CLC Number:

Shisheng SONG, Songlin SUN, Qin FANG, Caiwang PENG, Ting ZHOU, Haiying ZHU. Parameters Calibration of Discrete Element for Kitchen Waste Organic Fertilizer Bioconversion by Black Soldier Fly[J]. Journal of Agricultural Science and Technology, 2022, 24(6): 123-132.

宋世圣, 孙松林, 方芹, 彭才望, 周婷, 朱海英. 黑水虻生物转化餐厨垃圾有机肥离散元模型参数标定[J]. 中国农业科技导报, 2022, 24(6): 123-132.

Add to citation manager EndNote|Ris|BibTeX

URL: https://nkdb.magtechjournal.com/EN/10.13304/j.nykjdb.2021.0783

参数符号 Parameter symbol | 参数 Parameter | 低水平 Low level(-1) | 高水平 High level(1) | 文献 Reference |

|---|---|---|---|---|

| A | 泊松比 Poisson’s ratio | 0.10 | 0.30 | [ |

| B | 剪切模量 Shear modulus/MPa | 4.00 | 10.00 | [ |

| C | 颗粒密度 Particle density/(kg·m-3) | 1 500 | 2 500 | [ |

| D | 有机肥-有机肥碰撞恢复系数 Organic fertilizer-organic fertilizer restitution coefficient | 0.10 | 0.70 | [ |

| E | 有机肥-有机肥静摩擦系数 Organic fertilizer-organic fertilizer static friction coefficient | 0.75 | 0.85 | 测定Measure |

| F | 有机肥-有机肥滚动摩擦系数 Organic fertilizer-organic fertilizer rolling friction coefficient | 0.10 | 0.20 | 测定Measure |

| G | 有机肥-钢碰撞恢复系数 Organic fertilizer-steel restitution coefficient | 0.30 | 0.90 | [ |

| H | 有机肥-钢静摩擦系数 Organic fertilizer-steel static friction coefficient | 0.60 | 0.70 | 测定Measure |

| J | 有机肥钢滚动摩擦系数 Organic fertilizer-steel rolling friction coefficient | 0.01 | 0.11 | 测定Measure |

| K | JKR表面能 JKR surface energy/(J·m-2) | 0.05 | 0.15 | [ |

Table 1 Factors of Plackett-Burman Design

参数符号 Parameter symbol | 参数 Parameter | 低水平 Low level(-1) | 高水平 High level(1) | 文献 Reference |

|---|---|---|---|---|

| A | 泊松比 Poisson’s ratio | 0.10 | 0.30 | [ |

| B | 剪切模量 Shear modulus/MPa | 4.00 | 10.00 | [ |

| C | 颗粒密度 Particle density/(kg·m-3) | 1 500 | 2 500 | [ |

| D | 有机肥-有机肥碰撞恢复系数 Organic fertilizer-organic fertilizer restitution coefficient | 0.10 | 0.70 | [ |

| E | 有机肥-有机肥静摩擦系数 Organic fertilizer-organic fertilizer static friction coefficient | 0.75 | 0.85 | 测定Measure |

| F | 有机肥-有机肥滚动摩擦系数 Organic fertilizer-organic fertilizer rolling friction coefficient | 0.10 | 0.20 | 测定Measure |

| G | 有机肥-钢碰撞恢复系数 Organic fertilizer-steel restitution coefficient | 0.30 | 0.90 | [ |

| H | 有机肥-钢静摩擦系数 Organic fertilizer-steel static friction coefficient | 0.60 | 0.70 | 测定Measure |

| J | 有机肥钢滚动摩擦系数 Organic fertilizer-steel rolling friction coefficient | 0.01 | 0.11 | 测定Measure |

| K | JKR表面能 JKR surface energy/(J·m-2) | 0.05 | 0.15 | [ |

试验序号 No. | A | B | C | D | E | F | G | H | J | K | L | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 30.2 |

| 2 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 62.85 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 40.28 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 33.25 |

| 5 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 31.58 |

| 6 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 32.13 |

| 7 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 51.05 |

| 8 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 55.35 |

| 9 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 30.95 |

| 10 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 53.58 |

| 11 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 51.18 |

| 12 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 52.08 |

Table 2 Design and results of Plackett-Burman Design

试验序号 No. | A | B | C | D | E | F | G | H | J | K | L | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 30.2 |

| 2 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 62.85 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 40.28 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 33.25 |

| 5 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 31.58 |

| 6 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 32.13 |

| 7 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 51.05 |

| 8 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 55.35 |

| 9 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 30.95 |

| 10 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 53.58 |

| 11 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 51.18 |

| 12 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 52.08 |

方差来源 Soruce of variation | 标准化效应 Stdized effects | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value | 排序 Ranking |

|---|---|---|---|---|---|---|

| 模型Model | — | 1 526.53 | 10 | 772.40 | 0.028 0 | — |

| A | 2.58 | 19.92 | 1 | 100.78 | 0.063 2 | 5 |

| B | -2.73 | 22.30 | 1 | 112.86 | 0.059 8 | 4 |

| C | -0.87 | 2.25 | 1 | 11.40 | 0.183 3 | 8 |

| D | -21.28 | 1 358.94 | 1 | 6 876.07 | 0.007 7** | 1 |

| E | 1.37 | 5.60 | 1 | 28.35 | 0.118 2 | 9 |

| F | -0.090 | 0.024 | 1 | 0.12 | 0.785 3 | 10 |

| G | 3.83 | 44.01 | 1 | 222.67 | 0.042 6* | 3 |

| H | 2.53 | 19.25 | 1 | 97.42 | 0.064 3 | 6 |

| J | -4.05 | 49.21 | 1 | 248.98 | 0.040 3* | 2 |

| K | -1.29 | 5.02 | 1 | 25.39 | 0.124 7 | 7 |

Table 3 Significance analysis of Plackett-Burman test results

方差来源 Soruce of variation | 标准化效应 Stdized effects | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value | 排序 Ranking |

|---|---|---|---|---|---|---|

| 模型Model | — | 1 526.53 | 10 | 772.40 | 0.028 0 | — |

| A | 2.58 | 19.92 | 1 | 100.78 | 0.063 2 | 5 |

| B | -2.73 | 22.30 | 1 | 112.86 | 0.059 8 | 4 |

| C | -0.87 | 2.25 | 1 | 11.40 | 0.183 3 | 8 |

| D | -21.28 | 1 358.94 | 1 | 6 876.07 | 0.007 7** | 1 |

| E | 1.37 | 5.60 | 1 | 28.35 | 0.118 2 | 9 |

| F | -0.090 | 0.024 | 1 | 0.12 | 0.785 3 | 10 |

| G | 3.83 | 44.01 | 1 | 222.67 | 0.042 6* | 3 |

| H | 2.53 | 19.25 | 1 | 97.42 | 0.064 3 | 6 |

| J | -4.05 | 49.21 | 1 | 248.98 | 0.040 3* | 2 |

| K | -1.29 | 5.02 | 1 | 25.39 | 0.124 7 | 7 |

试验编号 Code | D | G | J | 堆积角 Repose angle/(°) | 相对误差 Relative errors/% |

|---|---|---|---|---|---|

| 1 | 0.70 | 0.30 | 0.11 | 36.58 | 11.51 |

| 2 | 0.58 | 0.42 | 0.09 | 39.38 | 4.74 |

| 3 | 0.46 | 0.54 | 0.07 | 47.65 | 15.26 |

| 4 | 0.34 | 0.66 | 0.05 | 56.23 | 36.02 |

| 5 | 0.22 | 0.78 | 0.03 | 59.34 | 43.54 |

| 6 | 0.10 | 0.90 | 0.01 | 61.25 | 48.16 |

Table 4 Design and results of steepest ascent test

试验编号 Code | D | G | J | 堆积角 Repose angle/(°) | 相对误差 Relative errors/% |

|---|---|---|---|---|---|

| 1 | 0.70 | 0.30 | 0.11 | 36.58 | 11.51 |

| 2 | 0.58 | 0.42 | 0.09 | 39.38 | 4.74 |

| 3 | 0.46 | 0.54 | 0.07 | 47.65 | 15.26 |

| 4 | 0.34 | 0.66 | 0.05 | 56.23 | 36.02 |

| 5 | 0.22 | 0.78 | 0.03 | 59.34 | 43.54 |

| 6 | 0.10 | 0.90 | 0.01 | 61.25 | 48.16 |

试验编号 Code | 水平 Level | 堆积角 Repose angle/(°) | ||

|---|---|---|---|---|

| D | G | J | ||

| 1 | 0 | -1 | 1 | 43.25 |

| 2 | 0 | 1 | 1 | 48.35 |

| 3 | -1 | 0 | -1 | 34.15 |

| 4 | 1 | 0 | 1 | 50.85 |

| 5 | 0 | 0 | 0 | 47.30 |

| 6 | 0 | 0 | 0 | 45.73 |

| 7 | -1 | 0 | 1 | 45.50 |

| 8 | 0 | 0 | 0 | 46.80 |

| 9 | 1 | -1 | 0 | 42.50 |

| 10 | 1 | 0 | -1 | 41.65 |

| 11 | 0 | 0 | 0 | 47.85 |

| 12 | -1 | 1 | 0 | 40.80 |

| 13 | 0 | -1 | -1 | 38.23 |

| 14 | 0 | 1 | -1 | 39.28 |

| 15 | 1 | 1 | 0 | 43.15 |

| 16 | 0 | 0 | 0 | 48.23 |

| 17 | -1 | -1 | 0 | 36.19 |

Table 5 Design and results of Box-Behnken Design

试验编号 Code | 水平 Level | 堆积角 Repose angle/(°) | ||

|---|---|---|---|---|

| D | G | J | ||

| 1 | 0 | -1 | 1 | 43.25 |

| 2 | 0 | 1 | 1 | 48.35 |

| 3 | -1 | 0 | -1 | 34.15 |

| 4 | 1 | 0 | 1 | 50.85 |

| 5 | 0 | 0 | 0 | 47.30 |

| 6 | 0 | 0 | 0 | 45.73 |

| 7 | -1 | 0 | 1 | 45.50 |

| 8 | 0 | 0 | 0 | 46.80 |

| 9 | 1 | -1 | 0 | 42.50 |

| 10 | 1 | 0 | -1 | 41.65 |

| 11 | 0 | 0 | 0 | 47.85 |

| 12 | -1 | 1 | 0 | 40.80 |

| 13 | 0 | -1 | -1 | 38.23 |

| 14 | 0 | 1 | -1 | 39.28 |

| 15 | 1 | 1 | 0 | 43.15 |

| 16 | 0 | 0 | 0 | 48.23 |

| 17 | -1 | -1 | 0 | 36.19 |

方差来源 Soruce of variation | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|

| 模型Model | 340.15 | 9 | 23.37 | 0.000 2** |

| D | 57.84 | 1 | 35.76 | 0.000 6** |

| G | 16.27 | 1 | 10.06 | 0.015 7* |

| J | 149.99 | 1 | 92.73 | <0.000 1** |

| DG | 3.92 | 1 | 2.42 | 0.163 5 |

| DJ | 1.16 | 1 | 0.71 | 0.425 9 |

| GJ | 4.10 | 1 | 2.54 | 0.155 4 |

| D2 | 34.95 | 1 | 21.61 | 0.002 3** |

| G2 | 55.82 | 1 | 34.51 | 0.000 6** |

| J2 | 6.72 | 1 | 4.16 | 0.080 9 |

| 残差Residual | 11.32 | 7 | ||

| 失拟项Lack of fit | 7.51 | 3 | 2.63 | 0.187 0 |

| 纯误差Pure error | 3.81 | 4 | ||

| 总和Sum | 351.48 | 16 |

Table 6 ANOVA of regression model of Box Behnken Design

方差来源 Soruce of variation | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|

| 模型Model | 340.15 | 9 | 23.37 | 0.000 2** |

| D | 57.84 | 1 | 35.76 | 0.000 6** |

| G | 16.27 | 1 | 10.06 | 0.015 7* |

| J | 149.99 | 1 | 92.73 | <0.000 1** |

| DG | 3.92 | 1 | 2.42 | 0.163 5 |

| DJ | 1.16 | 1 | 0.71 | 0.425 9 |

| GJ | 4.10 | 1 | 2.54 | 0.155 4 |

| D2 | 34.95 | 1 | 21.61 | 0.002 3** |

| G2 | 55.82 | 1 | 34.51 | 0.000 6** |

| J2 | 6.72 | 1 | 4.16 | 0.080 9 |

| 残差Residual | 11.32 | 7 | ||

| 失拟项Lack of fit | 7.51 | 3 | 2.63 | 0.187 0 |

| 纯误差Pure error | 3.81 | 4 | ||

| 总和Sum | 351.48 | 16 |

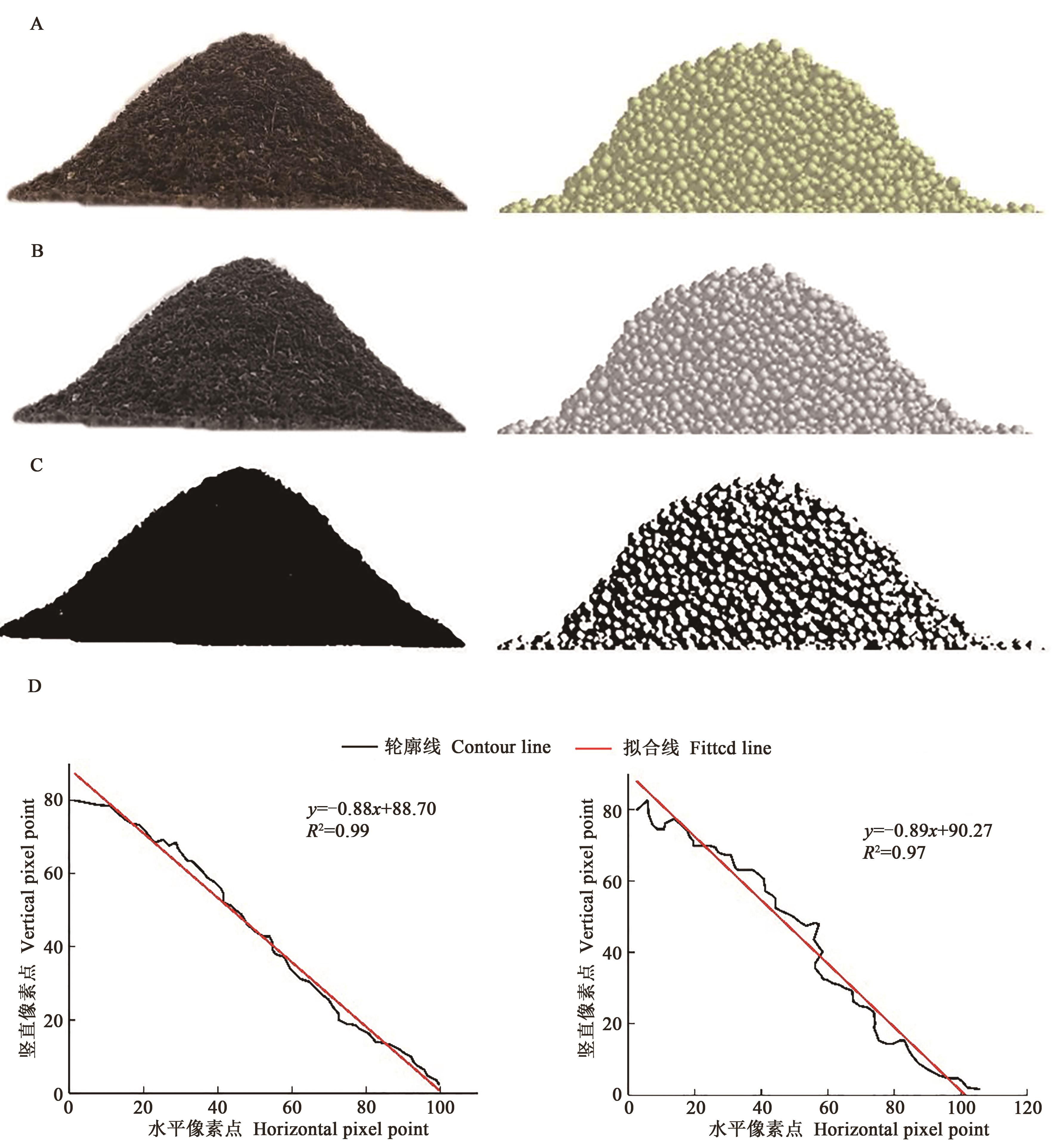

Fig. 5 Comparison of physical test and simulation testA: Physical test and simulation image; B: Grayscale processing; C: Binarization processing; D:Comparison of boundary contou. The left shows physical test and the right shows simulation test

| 1 | RAHMAN M A, SHAHAZI R, NOVA S N B, et al.. Biogas production from anaerobic co-digestion using kitchen waste and poultry manure as substrate—part 1: substrate ratio and effect of temperature [J/OL]. Biomass Convers. Bioresour., 2021 [2021-10-27]. . |

| 2 | ISHA A, D' SILVA T C, SUBBARAO P M V, et al.. Stabilization of anaerobic digestion of kitchen wastes using protein-rich additives: Study of process performance, kinetic modelling and energy balance [J/OL]. Bioresour. Technol., 2021, 337:125331[2021-03-05]. . |

| 3 | 谷士艳, 闫屹嵩, 张文一,等. 高盐高油对餐厨垃圾厌氧发酵酶活性及产VFAs的影响 [J]. 农业工程学报,2021,37(6):228-234. |

| GU S Y, YAN Y S, ZHANG W Y, et al.. Effects of high salt and high oil content on anaerobic fermentation enzyme activity and production of VFAs in food waste [J]. Trans. CSAE, 2021,37(6):228-234. | |

| 4 | 黄晶晶, 戴思慧, 张良,等.生活垃圾有机肥制造设备的设计与试验 [J]. 湖南农业大学学报(自然科学版),2019,45(3):332-336. |

| HUANG J J, DAI S H, ZHANG L, et al.. Design and experimental research on the organic fertilizer manufacturing equipment for domestic garbage [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2019, 45(3):332-336. | |

| 5 | 张晓林, 段永改, 贺永惠. 餐厨垃圾与鸡粪饲养黑水虻幼虫条件优化 [J]. 浙江农业科学,2021,62(06):1200-1203, 1258. |

| ZHANG X L, DUAN Y G, HE Y H. Optimization of feeding conditions of black soldier fly larvae by food waste and chicken manure [J]. J. Zhejiang Agric. Sci., 2021,62(6):1200-1203, 1258. | |

| 6 | LU Y, ZHANG S Y, SUN S B, et al.. Effects of different nitrogen sources and ratios to carbon on larval development and bioconversion efficiency in food waste treatment by black soldier fly larvae (Hermetia illucens) [J/OL]. Insects, 2021, 12(6):507[2021-03-05]. . |

| 7 | 尹靖凯,龚小燕,孙丽娜,等.黑水虻对餐厨垃圾养分转化研究[J].中国农业科技导报,2021,23(6):154-159. |

| YIN J K, GONG X Y, SUN L N, et al.. Study on the transformation of nutrients in kitchen waste by black soldier fly [J]. J. Agric. Sci. Tech. China, 2021,23(6):154-159. | |

| 8 | 张志剑,王先哲,许绍伟,等.虻粪二次堆肥生化特性的动态变化趋势及其微生物演替规律[J].微生物学报,2020,60(12):2664-2674. |

| ZHANG Z J, WANG X Z, XV S W, et al.. Dynamic features of biochemical property and microbial succession of black soldier fly larvae (Hermetia illucens L) vermicompost during secondary composting [J]. Acta Microbiol. Sin., 2020,60(12):2664-2674. | |

| 9 | 李逵,杨启志,雷朝亮,等.我国利用昆虫转化有机废弃物的发展现状及前景[J].环境昆虫学报,2017,39(2):453-459. |

| LI K, YANG Q Z, LEI C L, et al. Status and prospects of the transformation of organic wastes by insects in China [J]. J. Environ. Entomol., 2017,39(2):453-459. | |

| 10 | 王国强.离散单元法及其在EDEM上的实践[M]. 西安:西北工业大学出版社,2010: 1-155. |

| 11 | 胡国明.颗粒系统的离散元素法分析仿真[M]. 武汉:武汉理工大学出版社,2010: 1-302. |

| 12 | 韩树杰,戚江涛,坎杂,等.新疆果园深施散体厩肥离散元参数标定研究[J].农业机械学报,2021,52(4):101-108. |

| HAN S J, QI J T, KAN Z, et al. Parameters calibration of discrete element for deep application of bulk manure in Xinjiang orchard [J]. Trans. CSAM, 2021,52(4):101-108. | |

| 13 | 王韦韦,蔡丹艳,谢进杰,等.玉米秸秆粉料致密成型离散元模型参数标定[J].农业机械学报,2021,52(3):127-134. |

| WANG W W, CAI D Y, XIE J J, et al. Parameters calibration of eiscrete element model for corn stalk powder compression simulation [J]. Trans. CSAM, 2021,52(3):127-134. | |

| 14 | 石辰风,杨茂蕊,唐正馨,等.中药浸膏粉离散元模拟参数标定方法研究[J].中草药,2020,51(24):6205-6212. |

| SHI C F, YANG M R, TANG Z X, et al.. Calibration of discrete element simulation parameters of Chinese medicine extract powders [J]. China Tradit Herb Drugs, 2020,51(24):6205-6212. | |

| 15 | 彭才望,许道军,贺喜,等.黑水虻处理的猪粪有机肥离散元仿真模型参数标定[J].农业工程学报,2020,36(17):212-218. |

| PENG C W, XV D J, HE X, et al.. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen [J]. Trans. CSAE, 2020,36(17):212-218. | |

| 16 | 邢洁洁,张锐,吴鹏,等.海南热区砖红壤颗粒离散元仿真模型参数标定[J].农业工程学报,2020,36(5):158-166. |

| XING J J, ZHANG R, WU P, et al.. Parameter calibration of discrete element simulation model for latosol particles in hot areas of Hainan Province [J]. Trans. CSAE, 2020,36(5):158-166. | |

| 17 | 刘家平,刘胜芳.利用物理方法对餐厨垃圾分类处理研究[J].食品安全导刊,2017(18):117-118. |

| 18 | 任立斌.黑水虻生物转化餐厨垃圾试验的研究[D]. 兰州:兰州交通大学, 2020. |

| REN L B. The experimental Study on the biological transformation of food waste from black solider fly larva [D]. Lanzhou: Lanzhou Jiaotong University, 2020. | |

| 19 | 余参参,段宏兵,蔡兴奎,等.基于离散元仿真参数的微型薯物料测定[J].华中农业大学学报,2021,40(1):210-217. |

| YU C C, DUAN H B, CAI X K, et al.. Discrete element simulation parameters-based measurement of materials for potato minituber [J]. J. Huazhong Agric. Univ., 2021,40(1):210-217. | |

| 20 | 张晓明.有机肥颗粒热风干燥工艺及装备研究[D].北京:中国农业大学, 2017. |

| ZHANG X M. Study on the Drying Process and Equipment for Organic Feretilizer Pellets [D]. Beijing: China Agricultural University, 2017. | |

| 21 | 武涛,黄伟凤,陈学深,等.考虑颗粒间黏结力的黏性土壤离散元模型参数标定[J].华南农业大学学报(自然科学版),2017,38(3):93-98. |

| WU T, HUANG W F, CHEN X S, et al.. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles [J]. J. South China Agric. Univ. (Nat. Sci.), 2017,38(3):93-98. | |

| 22 | 林嘉聪,罗帅,袁巧霞,等.不同含水率蚯蚓粪颗粒物料流动性研究[J].农业工程学报,2019,35(9):221-227. |

| LIN J C, LUO S, YUAN Q X, et al.. Flow properties of vermicompost particle with different moisture contents [J]. Trans. CSAE, 2019,35(9):221-227. | |

| 23 | 罗帅,袁巧霞, GOUDA S, 等. 基于JKR粘结模型的蚯蚓粪基质离散元法参数标定[J].农业机械学报,2018,49(4):343-350. |

| LUO S, YUAN Q X, GOUDA S, et al.. Parameters calibration of vermicomposting nursery substrate with discrete element method based on JKR contact model [J]. Trans. CSAM, 2018,49(4):343-350. | |

| 24 | 温翔宇,袁洪方,王刚,等.颗粒肥料离散元仿真摩擦因数标定方法研究[J].农业机械学报,2020,51(2):115-122, 142. |

| WEN X Y, YUAN H F, WANG G, et al.. Calibration method of friction coefficient of granular fertilizer by discrete element simulation [J]. Trans. CSAM, 2020,51(2):115-122, 142. | |

| 25 | 马彦华,宋春东,宣传忠,等.苜蓿秸秆压缩仿真离散元模型参数标定[J].农业工程学报,2020,36(11):22-30. |

| MA Y H, SONG C D, XUAN C Z, et al.. Parameters calibration of discrete element model for alfalfa straw compression simulation [J]. Trans. CSAE, 2020,36(11):22-30. | |

| 26 | 葛宜元.试验设计方法与Design-Expert软件应用[M].哈尔滨:哈尔滨工业大学出版社,2015:1-207. |

| 27 | 李俊伟,佟金,胡斌,等.不同含水率黏重黑土与触土部件互作的离散元仿真参数标定[J].农业工程学报,2019,35(6):130-140. |

| LI J W, TONG J, HU B, et al.. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China [J]. Trans. CSAE, 2019,35(6):130-140. | |

| 28 | 郝建军,魏文波,黄鹏程,等.油葵籽粒离散元参数标定与试验验证 [J].农业工程学报,2021,37(12):36-44. |

| HAO J J, WEI W B, HUANG P C, et al.. Calibration and experimental verification of discrete element parameters of oil sunflower seeds [J]. Trans. CSAE, 2021,37(12):36-44. | |

| 29 | 张杰,温逸婷,高正辉,等.黑水虻的资源化利用研究现状[J].应用昆虫学报,2019,56(5):997-1006. |

| ZHANG J, WEN Y T, GAO Z H, et al.. Progress in research on, and the utilization of, Hermetia illucens [J]. China J. Appl. Entomol., 2019,56(5):997-1006. | |

| 30 | 彭才望,贺喜,孙松林,等.斗式黑水虻处理猪粪有机肥取料机设计与试验[J]. 农业机械学报,2021,52(2):145-156. |

| PENG C W, HE X, SUN S L, et al.. Design and experiment on shoveling eevice of pig manure organic rertilizer by Hermetia illucen transforming based on bucket-wheel mechanism [J]. Trans. CSAM, 2021,52(2):145-156. | |

| 31 | 彭才望,宋世圣,谢烨林,等.黑水虻虫沙双向集料装置参数优化与试验[J].河南农业大学学报,2021,55(4):689-697, 714. |

| PENG C W, SONG S S, XIE Y L, et al.. Parameter optimization and experiment for Hermetia illucens sand bidirectional aggregating device [J]. J. Henan Agric.Univ., 2021,55(4):689-697, 714. | |

| 32 | 蔡静.基于DEM的蛆粪混合物动力学与多维振动筛的优化设计[D]. 江苏镇江:江苏大学, 2018. |

| CAI J. Dynamics of maggots and manure based on DEM and optimal design of the multi-dimensional sieving machine [D]. Jiangsu Zhenjiang: Jiangsu University, 2018. |

| [1] | Haidong ZHANG, Zhixian TANG, Liyun ZHANG, Qi YU, Chaojun SONG. Optimization of Discrete Elemental Simulation Parameters for Forest Panax pseudoginseng Plantation Red Soil Based on GA-BP-GA [J]. Journal of Agricultural Science and Technology, 2025, 27(9): 120-130. |

| [2] | Xuelin DU, Ying LIU, Jiahua ZOU, Yu TU, Can ZHOU, Jinpeng CHENG. Crushing Effect of Double Tooth Roller Crushing Mechanism and Wall Breaker Crushing Mechanism on Kitchen Waste [J]. Journal of Agricultural Science and Technology, 2025, 27(9): 99-109. |

| [3] | Xiaobo XI, Jieyuan DING, Wendi ZHANG, Yangjie SHI, Yifu JIN, Ruihong ZHANG. Design and Experiment of Orchard Obstacle Avoidance Weeding Cultivator [J]. Journal of Agricultural Science and Technology, 2025, 27(7): 101-110. |

| [4] | Jing XU, Han LI, Pinglu CHEN, Jiangni LUO, Chenglu TANG, Muhua LIU. Calibration and Validation of Discrete Element Model for Camelliaoleifera Seed Meal [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 112-121. |

| [5] | Changlong FENG, Chunguang HUANG, Chenyang NING, Shuping LI, Kejin CHEN. Optimization of Performance and Characteristics of Spiral Drill Bit Excavation Mechanism for Planting Machine [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 89-98. |

| [6] | Xiangzhou TIAN, Fuqiang HE, Fajiang CHEN, Luxin ZHAN. Calibration of Discrete Elemental Parameters of Wood Powder with Different Moisture Content Based on Angle of Repose [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 118-128. |

| [7] | Guoqiang DUN, Lei WANG, Xinxin JI, Xinbo JIANG, Yu ZHAO, Na GUO. Calibration and Verification of Discrete Element Parameters of Jinxiang Purple Garlic Seeds [J]. Journal of Agricultural Science and Technology, 2024, 26(8): 131-139. |

| [8] | Jingwen QIANG, Wanqing WANG, Manyu TANG, Na ZHANG, Shuang WU, Wei HUA, Hengxuan SHAO, Yanling CHENG. Effects of Anaerobic Digestion of Kitchen Waste on Biogas Microorganisms and Environment [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 159-169. |

| [9] | Guoqiang DUN, Xingpeng WU, Xinxin JI, Fuli ZHANG, Wenyi JI, Yongzhen YANG. Simulation and Optimization of Soybean Plot Metering Device with Double Swing Plate [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 82-90. |

| [10] | Ming LI, Shuai DONG, Yongqiang PANG, Jiehua YAN, Wangzhong YE. Design Improvement and Test of Aeolian Sand Mixing Cutter [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 87-96. |

| [11] | Yuanhao HUANG, Lazhen QUAN, Guangfa HU, Wei QUAN, Fanggang SHI. Calibration of Discrete Element Contact Parameters for Various Materials and Soils with Different Moisture Content [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 98-109. |

| [12] | Lin CHEN, Nanhui YU, Lizong WANG, Jijun FAN, Gang LEI, Xiaopeng LIU, Long ZHOU, Jin ZHOU. Measurement of Contact Parameters and Discrete Element Simulation Calibration of Rice Bran and Broken Rice [J]. Journal of Agricultural Science and Technology, 2024, 26(2): 127-136. |

| [13] | Dafang YANG, Feixiang LI, Yuefeng GE, Yichen LI. Study on Fertilizer Discharge Performance of External Groove Wheel Fertilizer Applicator Based on Discrete Element Method [J]. Journal of Agricultural Science and Technology, 2024, 26(12): 88-97. |

| [14] | Hongbo WANG, Zhipeng FAN, Wulantuya, Chunguang WANG, Zhe MA. Parameter Calibration of Discrete Element Model for Simulation of Crushed Corn Stalk Screw Conveying [J]. Journal of Agricultural Science and Technology, 2023, 25(3): 96-106. |

| [15] | Miao YU, Haibin ZHOU, Jingtao DING, Hongsheng CHENG, Yujun SHEN, Shengyuan FAN, Xi ZHANG, Jian WANG, Pengxiang XU, Qiongyi CHENG. Calibration of Interparticle Contact Parameters of Kitchen Waste Composition Based on EDEM [J]. Journal of Agricultural Science and Technology, 2023, 25(12): 111-120. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号