中国农业科技导报 ›› 2022, Vol. 24 ›› Issue (5): 93-101.DOI: 10.13304/j.nykjdb.2021.0056

收稿日期:2021-01-17

接受日期:2021-04-11

出版日期:2022-05-15

发布日期:2022-06-06

通讯作者:

许静

作者简介:陈平录 E-mail:cpl757@163.com;

基金资助:

Pinglu CHEN( ), Shihua XIAO, Jing XU(

), Shihua XIAO, Jing XU( ), Muhua LIU

), Muhua LIU

Received:2021-01-17

Accepted:2021-04-11

Online:2022-05-15

Published:2022-06-06

Contact:

Jing XU

摘要:

针对联合收割机刚收获的稻谷由于含水率较大而易霉变的问题,提出了利用远红外联合热风将稻谷在收割谷物提升搅龙中直接干燥的方法。设计了红外加热器安装在搅龙中心的内加热和安装在搅龙外筒上的外加热2种方案,采用CFD-DEM耦合方法对稻谷运动、传热传质过程以及搅龙内的流场进行了仿真分析,并采用外筒加热方案试验对仿真结果进行了验证。结果表明:模拟值和试验值变化趋势一致,最大相对误差仅为8.34%,试验和仿真结果基本吻合;在不同搅龙转速、热风温度、热风风速和喂入量条件下,外加热方案脱水速率比内加热方案至少快2.91%,说明外加热方案干燥效果优于内加热方案;谷粒的升温随着搅龙转速、热风速度和喂入量的增大而减小,随着热风温度的增大而增大;谷粒脱水速率随着搅龙转速和喂入量的增大而减小,随着热风温度和热风速度的增大而增大。上述研究结果为联合收割机谷物提升搅龙中集成干燥装置的设计及干燥过程的优化提供了理论依据。

中图分类号:

陈平录, 肖石华, 许静, 刘木华. 收割机提升搅龙中干燥稻谷的CFD-DEM数值模拟[J]. 中国农业科技导报, 2022, 24(5): 93-101.

Pinglu CHEN, Shihua XIAO, Jing XU, Muhua LIU. CFD-DEM Simulation of Paddy Drying in Lifting Screw Conveyor of Harvester[J]. Journal of Agricultural Science and Technology, 2022, 24(5): 93-101.

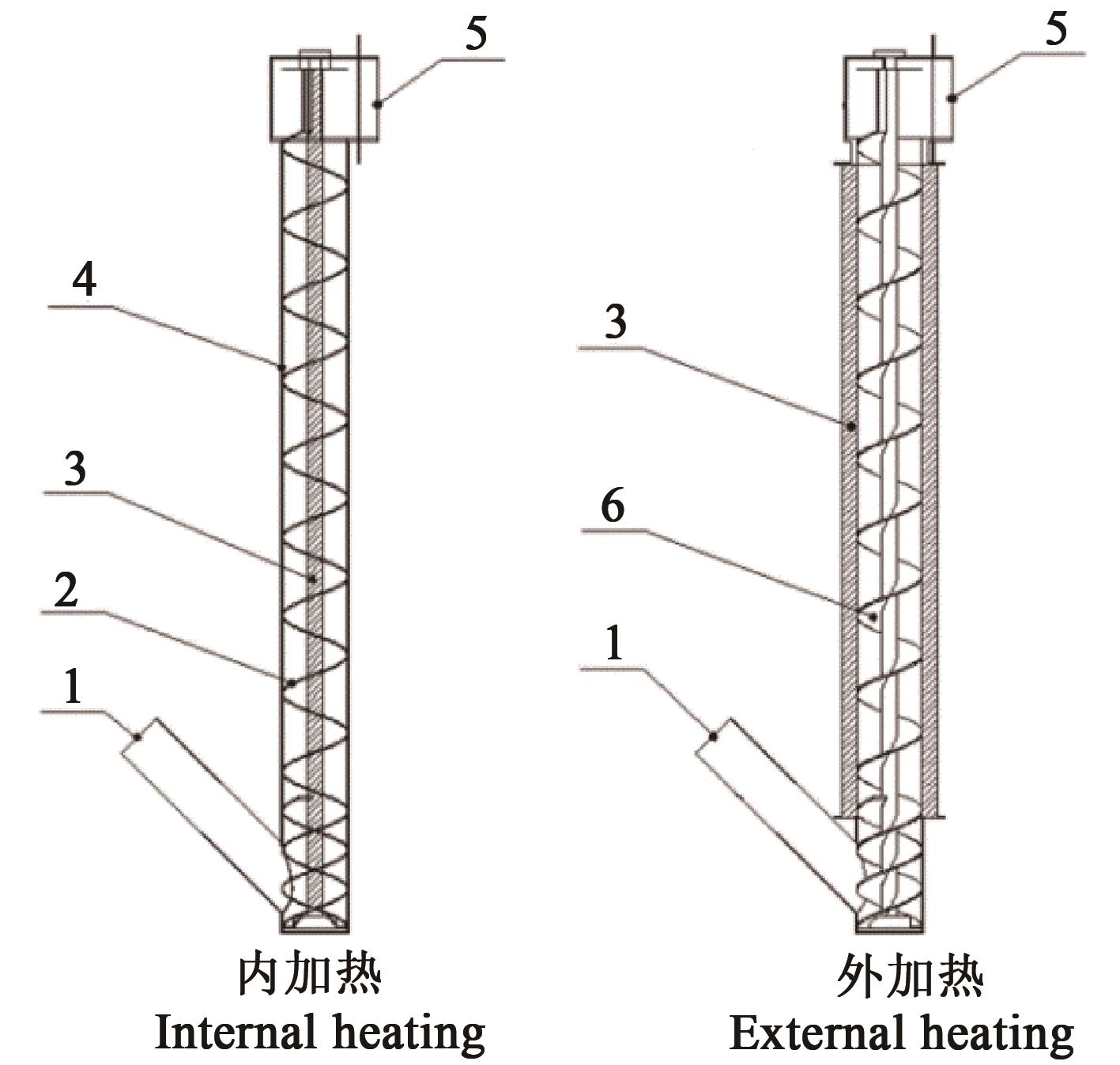

图1 在机干燥装置结构注:1—进料口(热风进口);2—无轴搅龙;3—红外加热管;4—外筒;5—出料口(干燥废气出口);6—有轴搅龙。

Fig.1 Structure of drying device in combine harvesterNote:1—Inlet (hot air inlet); 2—Shaftless screw conveyor; 3—Infrared heating tube; 4—Shell; 5—Outlet (exhaust outlet); 6—Screw conveyor.

| 材料 Material | 密度Density/(kg·m-3) | 弹性模量Hear modulus/(N·m-2) | 泊松比 Poisson’s ratio |

|---|---|---|---|

| 稻谷 Paddy | 1 086 | 8.65×107 | 0.25 |

| 钢 steel | 7 850 | 7×109 | 0.29 |

表1 颗粒模型材料参数

Table 1 Material parameters of particle model

| 材料 Material | 密度Density/(kg·m-3) | 弹性模量Hear modulus/(N·m-2) | 泊松比 Poisson’s ratio |

|---|---|---|---|

| 稻谷 Paddy | 1 086 | 8.65×107 | 0.25 |

| 钢 steel | 7 850 | 7×109 | 0.29 |

接触形式 Form of contact | 恢复系数 Coefficient of restitution | 静摩擦系数 Coefficient of static friction | 动摩擦系数 Coefficient of rolling friction |

|---|---|---|---|

| 稻谷-稻谷Paddy-paddy | 0.40 | 0.81 | 0.01 |

| 稻谷-钢Paddy-steel | 0.56 | 0.35 | 0.02 |

表 2 颗粒模型接触参数

Table 2 Contact parameters of particle model

接触形式 Form of contact | 恢复系数 Coefficient of restitution | 静摩擦系数 Coefficient of static friction | 动摩擦系数 Coefficient of rolling friction |

|---|---|---|---|

| 稻谷-稻谷Paddy-paddy | 0.40 | 0.81 | 0.01 |

| 稻谷-钢Paddy-steel | 0.56 | 0.35 | 0.02 |

| 1 | 唐庆春,赵立欣.2019年黑龙江省稻米市场形势分析及后市展望[J].农业展望,2020,16(4):3-6. |

| TANG Q C, ZHAO L X. Analysis of rice market situation and future prospects in Heilongjiang Province in 2019 [J]. Agric. Prospects, 2020, 16(4):3-6. | |

| 2 | 姚瑶.基于自回热理论的稻谷流化床干燥系统设计与研究[D].南京:南京航空航天大学,2017. |

| YAO Y. Design and research of rice fluidized bed drying system based on self-regenerative theory [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017. | |

| 3 | GAO W Z, FENG L M, LIU Z J. Design and analysis of engine exhaust gas energy recovery system [J]. Environ. Sci. Eng., 2008, 2(12):1-5. |

| 4 | 李素云,夏朝勇,朱文学.红外辐射在谷物干燥中的应用[J].粮食与食品工业,2007,14(1):44-46. |

| LI S Y, XIA C Y, ZHU W X. Application of infrared radiation in drying grain [J]. Cereal Food Ind., 2007, 14(1):44-46. | |

| 5 | 夏朝勇,朱文学,张仲欣,等.红外对流组合干燥稻谷试验[J].农业机械学报,2006,37(8):235-238. |

| 6 | 姜亚南.基于余热回收的粮食烘干系统的设计与实现[J].安徽农业科学,2016,44(26):228-230. |

| JIANG Y N. Design and implementation of grain drying system based on waste heat recovery [J]. J. Anhui Agric. Sci., 2016, 44(26):228-230. | |

| 7 | 白继伟,罗书强,叶进,等.多功能拖拉机发动机余热利用系统设计[J].农机化研究,2008,12:195-197. |

| BAI J W, LUO S Q, YE J, et al.. Design of multi-functional tractor engine waste heat utilization system [J]. J. Agric. Mechan. Res., 2008, 12:195-197. | |

| 8 | 吕欢.全太阳能木材干燥室性能测试及流场模拟优化[D].北京:北京林业大学, 2016. |

| LYU H. Performance test and flow field simulation optimization of all-solar wood drying chamber [D]. Beijing: Beijing Forestry University, 2016. | |

| 9 | 王仕琪.花生干燥过程中湿热传递机理及实验研究[D].郑州:河南工业大学,2020. |

| WANG S Q. Mechanism and experimental study of moisture and heat transfer in peanut drying process [D]. Zhengzhou: Henan University of Technology, 2020. | |

| 10 | 汪喜波,胡琼,肖波,等.稻谷红外辐射与对流联合干燥过程的模型模拟[J].农业机械学报,2013,44(9):145-151. |

| WANG X B, HU Q, XIAO B, et al.. Simulation of drying process of rice by combination of infrared radiation and convection [J]. Trans. Chin. Soc. Agric. Mach., 2013, 44(9):145-151. | |

| 11 | 高敏.稻谷籽粒热风干燥过程中热质传递模拟[D].天津:天津科技大学, 2017. |

| GAO M. Simulation of heat and mass transfer in rice grain during hot air drying [D]. Tianjin: Tianjin University of Science and Technology, 2017. | |

| 12 | WANG Z, HURTER S, YOU Z, et al.. Influences of negative pressure on air-leakage of coalseam gas extraction: Laboratory and CFD-DEM simulations [J/OL]. J. Pet. Sci. Eng., 2021, 196:107731 [2021-02-28]. . |

| 13 | SHAHAB G, RAHMAT S, REZA Z, et al.. Review and implementation of CFD-DEM applied to chemical process systems [J/OL]. Chem. Eng. Sci., 2020, 221:115646 [2021-02-28]. . |

| 14 | 马华庆,赵永志.喷动流化床中杆状颗粒混合特性的CFD-DEM模拟[J].浙江大学学报(工学版),2020, 54(7):1347-1354. |

| MA H Q, ZHAO Y Z. CFD-DEM investigation on mixing of rod-like particles in spout-fluid bed [J]. J. Zhejiang Univ. (Eng. Sci.), 2020, 54(7):1347-1354. | |

| 15 | 李云川,赵崤隆,石平平,等.基于CFD-DEM耦合的土壤渗透性数值分析[J].江苏农业科学,2020,48(16): 255-259. |

| LI Y C, ZHAO Y L, SHI P P, et al.. Numerical analysis of soil permeability based on CFD-DEM coupling [J]. Jiangsu Agric. Sci., 2020, 48(16):255-259. | |

| 16 | HOBBS A. Simulation of an aggregate dryer using coupled CFD and DEM methods [J]. Int. J. Computational Fluid Dynamics, 2009, 23(2):199-207. |

| 17 | 石林榕,吴建民,赵武云,等.基于CFD-EDEM耦合的小区玉米帘式滚筒干燥箱数值模拟[J].干旱地区农业研究,2014,32(6):273-278. |

| SHI L R, WU J M, ZHAO W Y, et al.. Numerical simulation of corn curtain drying oven based on CFD-EDEM coupling [J]. Agric. Res. Arid Areas, 2014, 32(6):273-278. | |

| 18 | 虞文俊,吴瑞梅,李红,等.基于Fluent-EDEM耦合的茶叶红外杀青机滚筒内流场数值模拟[J].食品与机械,2019,35(8):104-109. |

| YU W J, WU R M, LI H, et al.. Numerical simulation of flow field in tea infrared cleaning machine drum based on fluent and EDEM coupling [J]. Food Mach., 2019, 35(8):104-109. | |

| 19 | 胡国明.颗粒系统的离散元素法分析仿真[M].武汉:武汉理工大学出版社,2010:87-88. |

| HU G M. Analysis and Simulation of Particle System by Discrete Element Method [M]. Wuhan: Wuhan University of Technology Press, 2010:87-88. | |

| 20 | 朱兰.基于HDG的混合网格法的应用研究[D].成都:电子科技大学,2017. |

| ZHU L. Application research of hybrid mesh method based on HDG [D]. Chengdou: University of Electronic Science and Technology of China, 2017. | |

| 21 | 原建博,李骅,吴崇友,等.基于离散单元法的水稻籽粒快速颗粒建模研究[J].南京农业大学学报,2018,41(6):1151-1158. |

| YUAN J B, LI H, WU C Y, et al.. Fast grain modeling of rice based on discrete element method [J]. J. Nanjing Agric.Univ., 2018, 41(6):1151-1158. | |

| 22 | 王润发.粮食红外线辅助热风干燥工艺系统设计[D].广州:华南农业大学,2016. |

| WANG R F. Design of grain infrared assisted hot air drying process system [D]. Guangzhou: South China Agricultural University, 2016. | |

| 23 | 王珊珊.稻谷籽粒干燥玻璃化转变过程数值模拟[D].天津:天津科技大学,2019. |

| WANG S S. Numerical simulation of drying vitrification process of rice grain [D]. Tianjin: Tianjin University of Science and Technology, 2019. | |

| 24 | 郑刚,孙丽琴.不同干燥温度和干燥风速对稻谷品质的影响研究[J].粮油食品科技,2020,28(4):173-176. |

| ZHENG G, SUN L Q. Study on the effect of different drying temperature and drying wind speed on rice quality [J]. Sci. Technol. Cereals Oils Food, 2020, 28(4):173-176. |

| [1] | 胡华鹏, 张绪坤, 谌佳君, 潘杨杨, 杨佩林, 鲁志. 茶渣双轴搅拌干燥机结构优化及含水率模拟分析[J]. 中国农业科技导报, 2025, 27(4): 120-132. |

| [2] | 钟国良, 万霖, 车刚, 唐浩, 曲天奇, 张骐麟. 干燥参数对稻谷热风干燥速率及能耗的影响[J]. 中国农业科技导报, 2025, 27(3): 95-103. |

| [3] | 陈子民, 莫江婷, 陈广生, 郭小璇, 朱贤文. 基于Fluent的顶风式热泵干燥箱气流场分析及优化[J]. 中国农业科技导报, 2024, 26(10): 135-144. |

| [4] | 刘大为, 秦锋, 廖骞, 王修善, 谢方平, 李铁辉. 南方籼稻热风干燥特性及其工艺参数优化[J]. 中国农业科技导报, 2024, 26(8): 93-102. |

| [5] | 肖瑶, 吴明亮. 计算流体力学在农业工程中的应用现状与发展趋势[J]. 中国农业科技导报, 2023, 25(8): 1-9. |

| [6] | 周书娴, 石毅新, 蒋蘋. 基于CFD两级注入式射流混合器设计与试验研究[J]. 中国农业科技导报, 2021, 23(6): 86-96. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||